Multi-dimensional warm-keeping cotton with heat reflection function as well as production method and application of multi-dimensional warm-keeping cotton

A technology of heat reflection and thermal insulation cotton, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc. It can solve the problems of insufficient raw materials, hollow fibers are easy to be flattened, and downstream enterprises are troubled by material preparation, achieving the effect of low weight and excellent thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

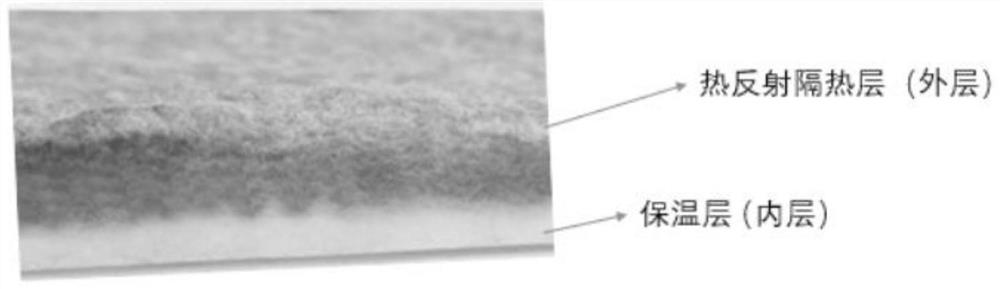

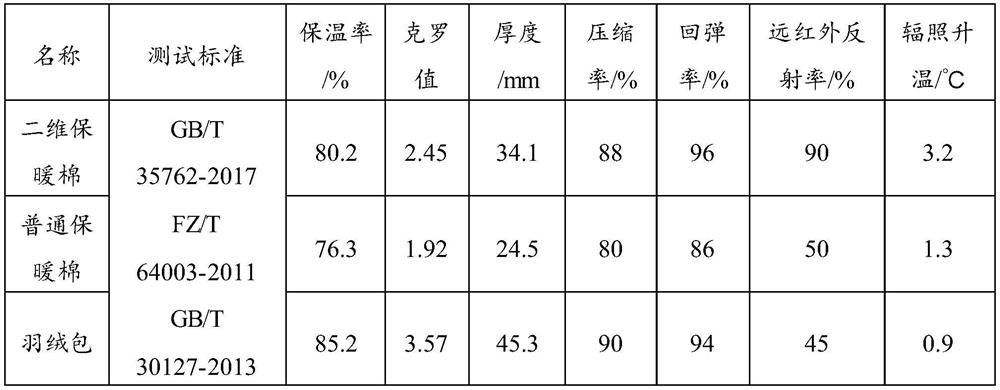

[0054] Name: two-dimensional thermal cotton (2 layers);

[0055] Gram weight: 150g / m 2 ;

[0056] Composition: The innermost three-dimensional crimped polyimide fiber has a fineness of 0.011-0.24dtex and a length of 45-60mm; the three-dimensional crimped acrylic fiber has a fineness of 0.010-0.24dtex and a length of 50-60mm; the low-melting point polyester fiber has a fineness of 1.8-2.30dtex, the length is 30-40mm; the contents of the three kinds of fibers are 60%, 35%, 5% respectively; 65mm; the fineness of metal-coated polyester fiber is 1.5-1.7dtex, and the length is 45-60mm; the fineness of low-melting point polyester fiber is 1.8-3.30dtex, and the length is 30-40mm; the contents of the three fibers are 40% and 55% respectively , 5%.

[0057] The production process and process are as follows:

[0058] 1) Prepare each layer of fiber raw materials according to the weight ratio, loosen the different fiber raw materials, and fully mix them evenly;

[0059] 2) Combing and...

Embodiment 2

[0071] Name: three-dimensional thermal cotton (three layers);

[0072] Gram weight: 200g / m 2 ;

[0073] Composition: The innermost three-dimensional crimped polyimide fiber has a fineness of 0.011-0.24dtex and a length of 45-60mm; the three-dimensional crimped acrylic fiber has a fineness of 0.01-0.24dtex and a length of 50-60-mm; low melting point polyester fiber The fineness is 1.8-2.30dtex, and the length is 30-40-mm; the contents of the three fibers are 55%, 40%, and 5% respectively; the outermost three-dimensional crimped polyimide fiber fineness is 0.2-0.44dtex, The length is 45-65mm; the fineness of metal-coated polyester fiber is 1.0-1.5dtex, and the length is 45-60mm; the fineness of low-melting point polyester fiber is 1.8-3.30dtex, and the length is 30-40mm; the content of the three fibers is 45 %, 50%, 5%; the three-dimensional crimped polyimide fiber in the middle layer has a fineness of 0.5-0.9dtex and a length of 35-55mm; the three-dimensional crimped acrylic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com