A kind of color heat reflective paint and its preparation method and application

A technology of heat-reflecting and heat-insulating coatings, applied in the field of coatings, can solve the problems of heat-reflecting performance degradation, single color, and reduced heat insulation effect, and achieve the effects of reducing surface temperature, prolonging service life, and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

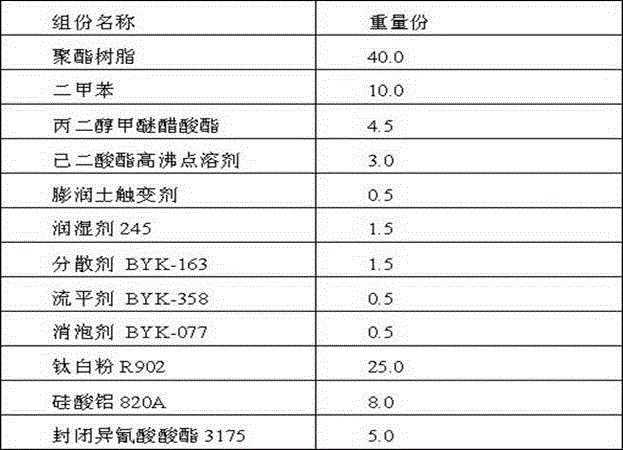

[0059] A preparation method of a gray heat reflective coating metal plate, the method comprises the following steps:

[0060] 1) White heat reflective primer

[0061]

[0062] Gray Insulation Paint Finish

[0063]

[0064] The coating preparation process:

[0065] (1) Preparation of primer:

[0066] First put 40.0 parts of polyester resin into the stirring tank, add 10.0 parts of xylene, 4.5 parts of propylene glycol methyl ether acetate, and 3.0 parts of adipate ester high-boiling point solvents, and stir evenly; add 0.5 parts of bentonite thixotropic agent in proportion, After stirring at high speed for 0.5 hours, check whether the thixotropic agent has been stirred evenly (no granular); add 1.5 parts of dispersant, 1.5 parts of wetting agent, 0.5 parts of defoamer, 0.5 parts of leveling agent in sequence, and stir evenly ; Add 25.0 parts of titanium dioxide pigment and 5.0 parts of aluminum silicate in proportion, and stir for 0.5-1 hour until the dispersion is uni...

Embodiment 2

[0076] A method for preparing a brown heat-reflective coating metal plate, the method comprising the following steps:

[0077] 1) White heat reflective primer

[0078]

[0079] Brown thermal insulation paint finish

[0080]

[0081] The coating preparation process:

[0082] (1) Preparation of primer:

[0083] First put 28.0 parts of epoxy resin into the stirring tank, then add 25.0 parts of xylene and 5.0 parts of n-butanol, and stir evenly; add 1.0 parts of bentonite thixotropic agent in proportion, and after stirring at high speed for 0.5 hours, check whether the thixotropic agent has been stirred Uniform (no granular); add 1.5 parts of dispersant, 0.5 parts of leveling agent in proportion, and stir evenly; add 25.0 parts of titanium dioxide pigment, 5.0 parts of talcum powder, 8.0 parts of zirconium silicate in proportion, and stir for 0.5-1 Hours, until the dispersion is uniform; put the above slurry into a sand mill, grind until the fineness reaches 20-25 microns...

Embodiment 3

[0093] A method for preparing a beige heat-reflective coating metal plate, the method comprising the following steps:

[0094] 1) White heat reflective primer

[0095]

[0096] Beige thermal insulation paint finish

[0097]

[0098] The coating preparation process:

[0099] (1) Preparation of primer:

[0100] First put 40.0 parts of polyester resin into the stirring tank, add 10.0 parts of xylene, 4.5 parts of propylene glycol methyl ether acetate, and 3.0 parts of adipate ester high-boiling point solvents, and stir evenly; add 0.5 parts of bentonite thixotropic agent in proportion, After stirring at high speed for 0.5 hours, check whether the thixotropic agent has been stirred evenly (no granular); add 1.5 parts of dispersant, 1.5 parts of wetting agent, 0.5 parts of defoamer, 0.5 parts of leveling agent in sequence, and stir evenly ; Add 25.0 parts of titanium dioxide pigment and 5.0 parts of aluminum silicate in proportion, and stir for 0.5-1 hour until the dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com