New Energy Saving Stoves

A new type of stove technology, applied in the field of stoves, can solve the problems of increased energy consumption of thermal insulation performance, poor thermal insulation performance, low thermal efficiency, etc., and achieves the effects of protecting service life, good anti-fall performance and improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

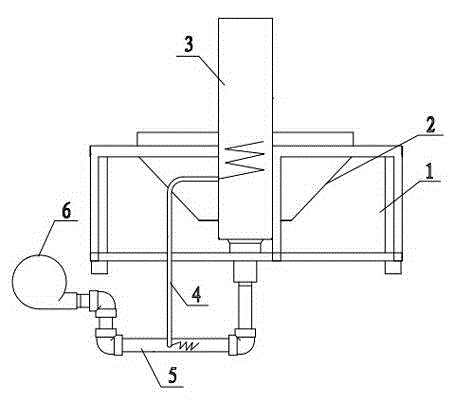

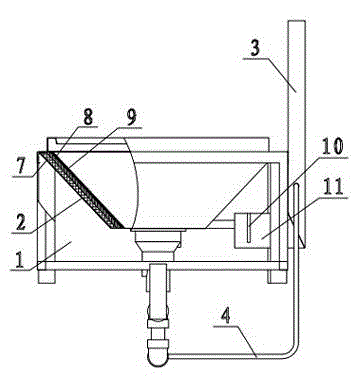

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] A new type of energy-saving stove, including a stove 1, a furnace core, a furnace 2, an air inlet, an air inlet and a chimney 3. The furnace 2 is connected through the smoke exhaust pipe 11, the air inlet is connected with the external air intake device through the air inlet pipe, and the air inlet is connected with the external blower 6 through the air inlet pipe 5; , tin platinum plate 8 and metal mesh 9, the furnace ring can be set as two parts enclosed, heat insulation plate 7 is made of polycrystalline mullite fiber, the thickness of the heat insulation plate is 2-6cm, tin platinum plate 8 The thickness is 0.04mm. The metal mesh 9 is composed of 4-10 layers of iron-chromium-aluminum meshes with different mesh numbers and diameters. , Coating the surface of the Fe-Cr-Al mesh with a high-temperature-resistant coating can increase the amount of heat reflection an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com