Welding point detection equipment for liquid crystal display module

A liquid crystal display module and detection equipment technology, applied to measuring devices, instruments, mechanical devices, etc., can solve problems such as low efficiency, achieve the effect of preventing waste and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

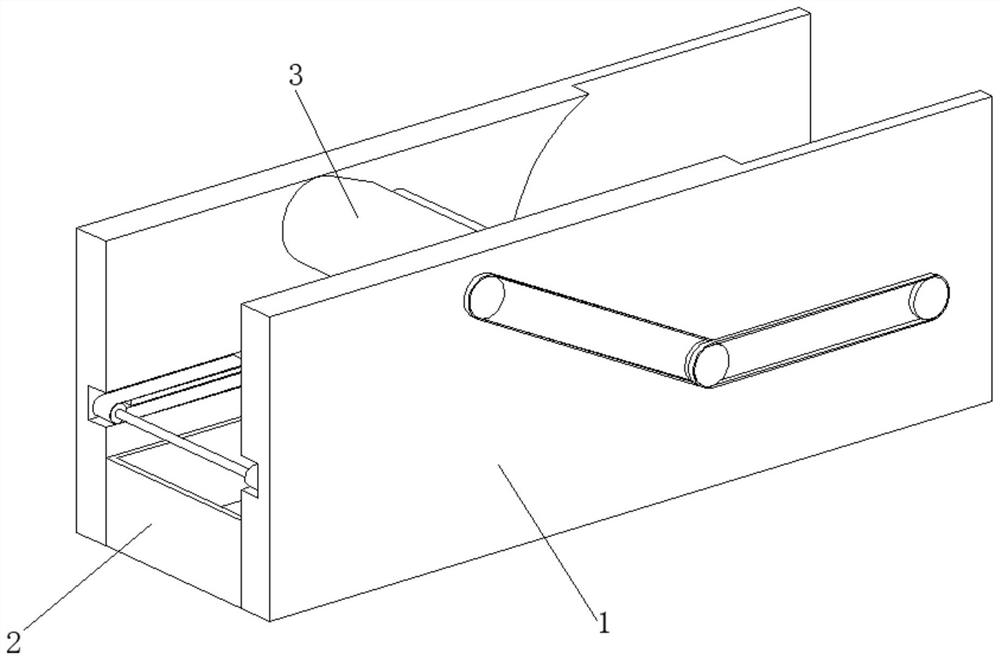

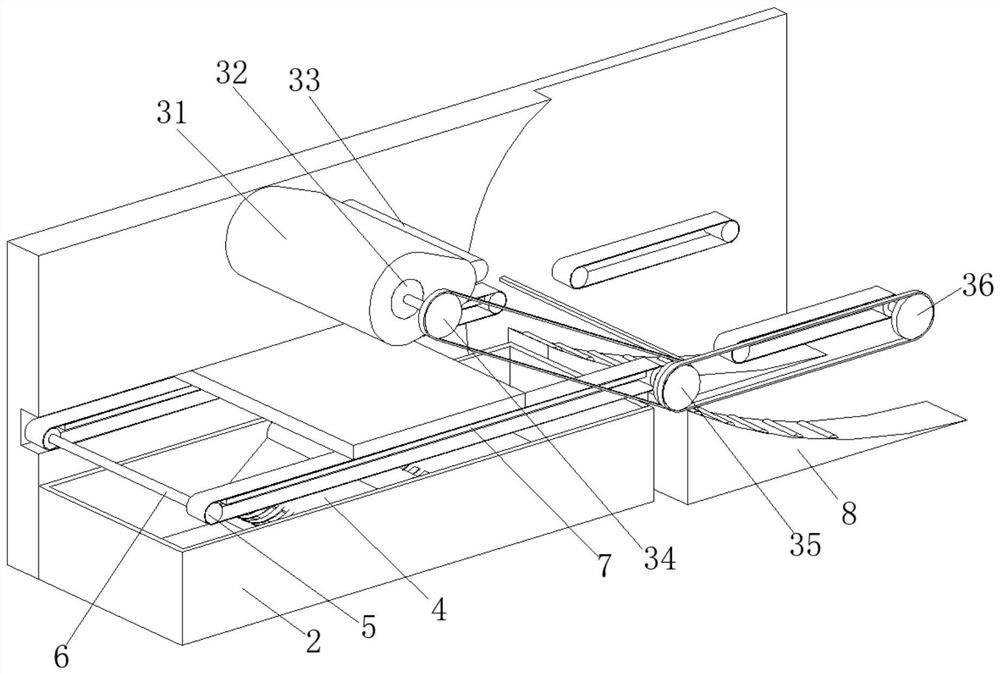

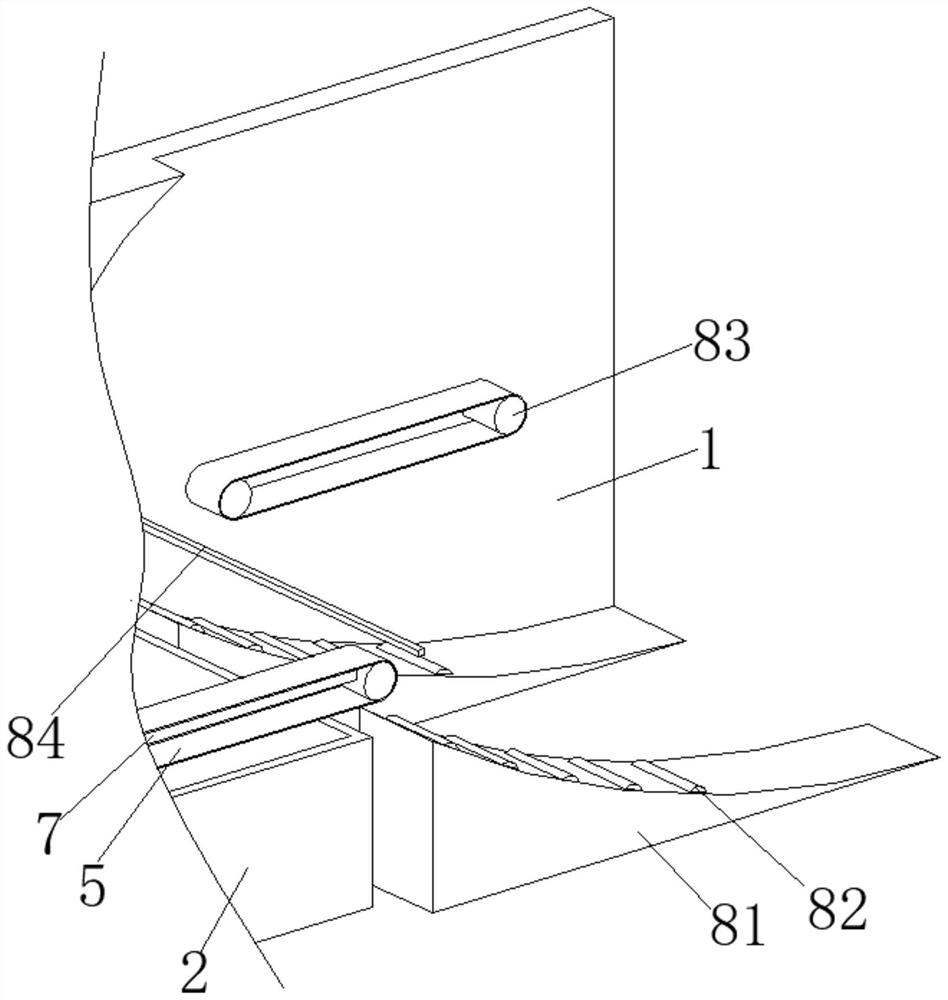

[0030] A kind of welding point detection equipment of liquid crystal display module, such as Figure 1-Figure 6 As shown, including a mounting plate 1, it is characterized in that: the surface of the mounting plate 1 is fixedly connected with a collection box 2, the surface of the mounting plate 1 is provided with a transmission device 3, and the transmission device 3 is located above the collection box 2, the collection box 2 The inner wall is provided with a collection device 4, and the number of mounting plates 1 is set to two, and the inner walls of the two mounting plates 1 are equipped with a No. The inner wall of the mounting plate 1 is fixedly connected with a support plate 7, the inner wall of the mounting plate 1 is provided with a discharge device 8, and the discharge device 8 is located on the right side of the collection box 2, the transmission device 3 includes a cam 31, and the inner wall of the cam 31 is fixedly connected with a rotating Shaft 32, the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com