Air frying food processor

A food processor and air frying technology, which is applied to kitchen utensils, home utensils, roasters/barbecue grids, etc., can solve the problems of complex buckle structure, difficult cleaning, complicated operation, etc., and achieves simple structure and convenient cleaning. , easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail

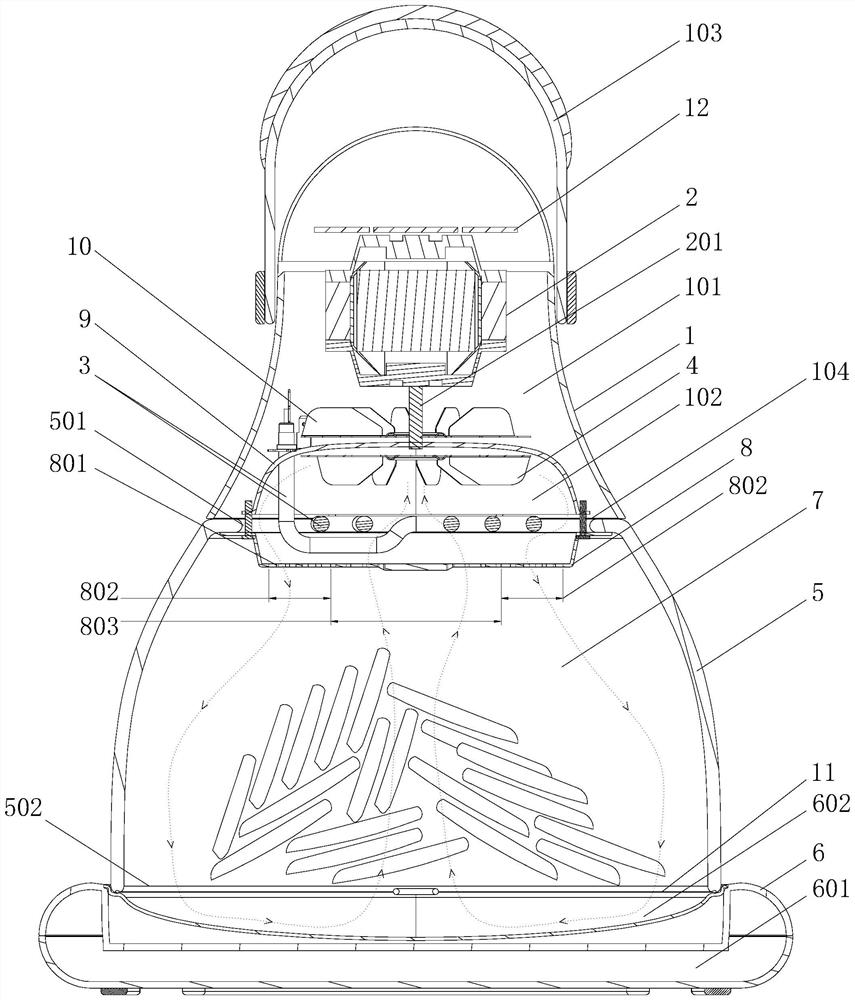

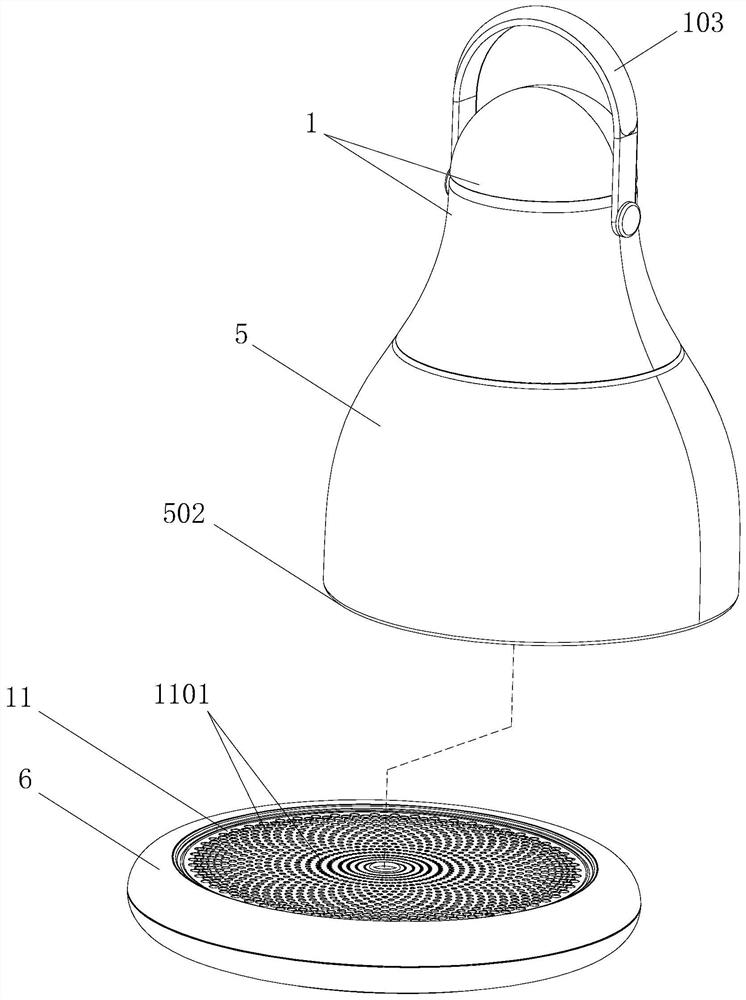

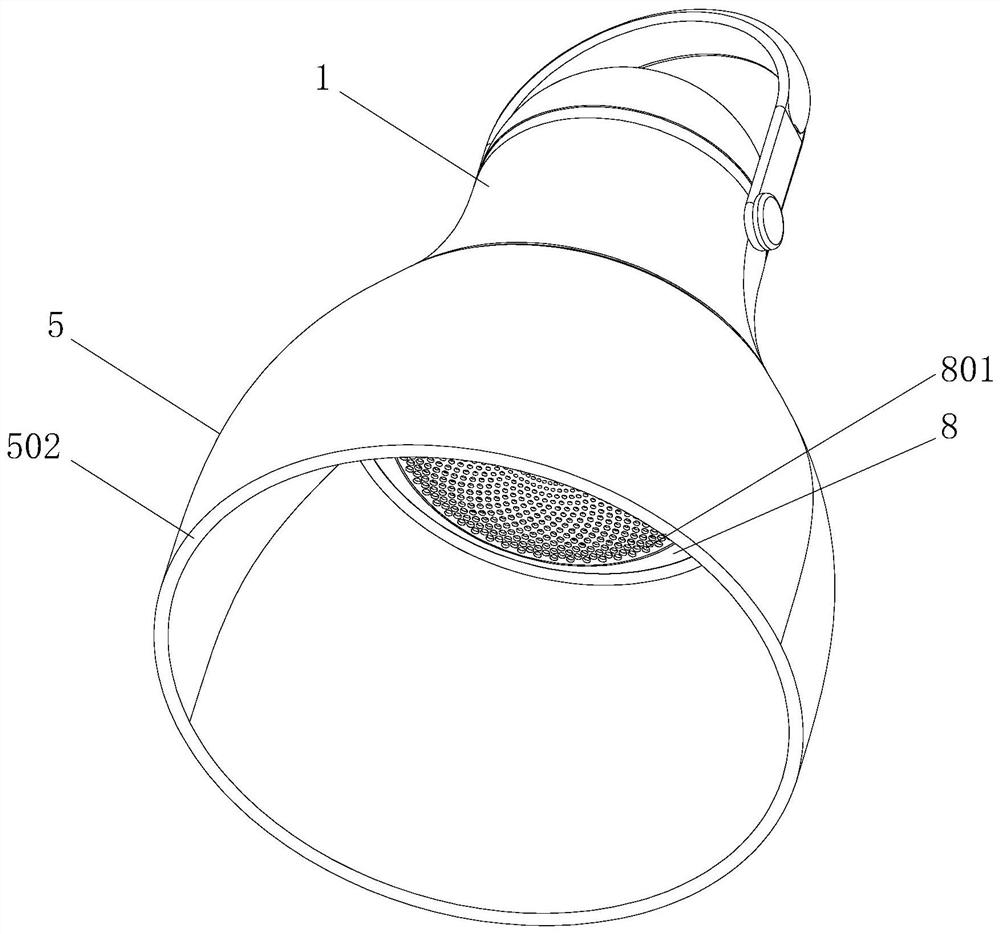

[0028] Such as Figure 1-3 As shown, an air frying food cooking machine includes a host 1, a control panel 12 is arranged on the host 1, a motor 2 and a heating element 3 are arranged in the host 1, a fan 4 is connected to the output end 201 of the motor 2, and the control panel 12 They are respectively electrically connected to the motor 2, the heating element 3 or other temperature sensors or electronic components. It is characterized in that the bottom of the host 1 is connected with a cover body 5 extending downward, and the lower opening 502 of the cover body 5 is supported by the chassis 6. The main engine 1 and the cover body 5 are detachably arranged relative to the chassis 6. The oil leakage plate 11 on the chassis 6 and the inner wall of the cover body 5 form a food frying cavity 7, and food is placed in the food frying cavity 7, and the fan 4 in the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com