Industrial glass fiber reinforced plastic washing tower

A glass fiber reinforced plastic and washing tower technology, which is applied in the field of washing towers, can solve the problems of reducing washing efficiency, reducing cooling efficiency of flue gas, etc., and achieves the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

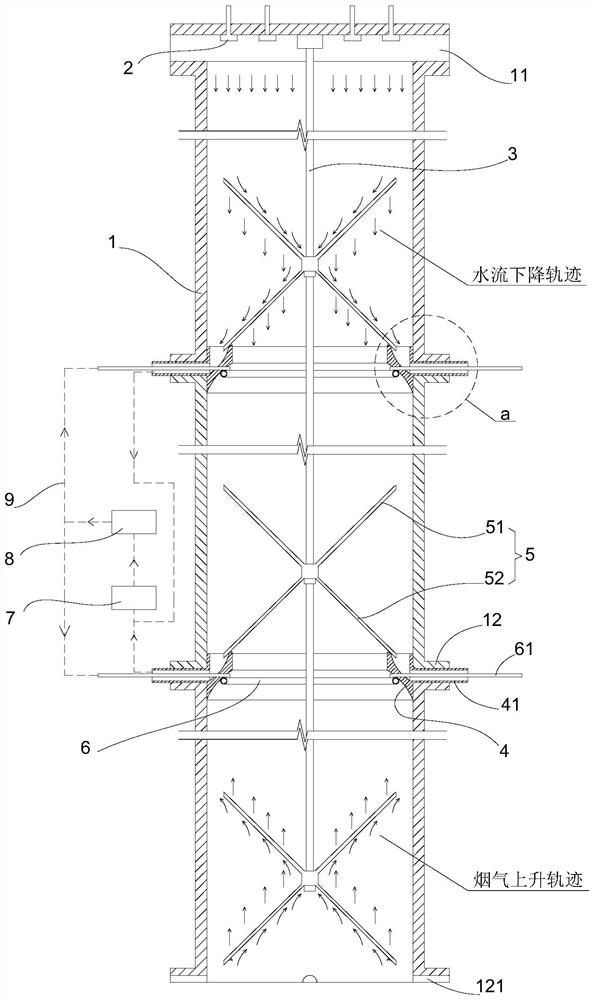

[0033] Such as Figure 1-8 As shown, an industrial glass fiber reinforced plastic washing tower includes a tower body, and the tower body includes several sections of rising pipes 1. The end faces of the rising pipes 1 are provided with flange surfaces 12, and several sections of rising pipes 1 are detachable through the flange surfaces 12. The uppermost rising pipe 1 is provided with a spraying device 2 inside, and the spraying device 2 sprays the inside of the rising pipe 1 to wash the rising flue gas.

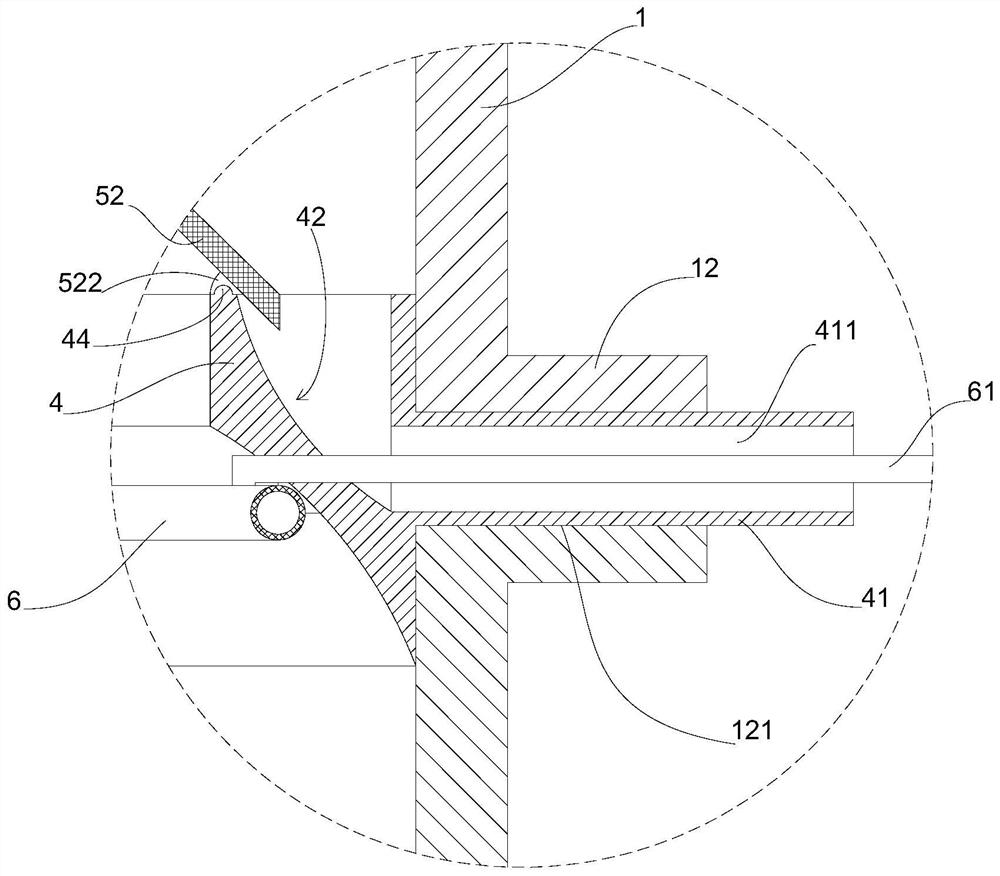

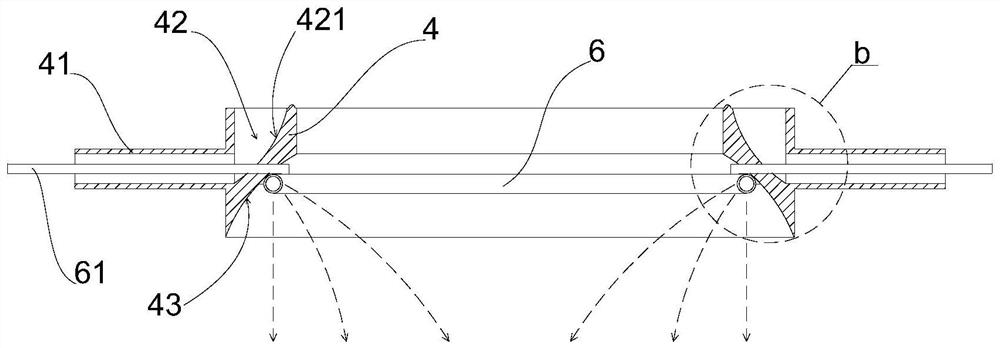

[0034] Each flange surface 12 of the riser pipe 1 is provided with several installation grooves 121, and the installation grooves 121 are preferably arranged as semicircles, so that when two sections of riser pipes 1 are connected into one body, the two semicircle installation grooves 121 is closed to form a circular installation hole, which is convenient for sealing. The inner wall of the rising pipe 1 is closely attached to a sewage discharge ring 4, and the interior of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com