Multi-color electrochromic structure and device with high brightness, saturation and purity and manufacturing method of multi-color electrochromic structure and device

An electrochromic layer and saturation technology, which is applied in the field of optics or optoelectronics, can solve problems such as the need to improve brightness, small color gamut, and low color saturation of colorful films, and achieve brilliant colors, stable colors, and high manufacturability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0102] In some embodiments, the preparation method of the colorful electrochromic structure includes: by physical or chemical deposition, such as coating, printing, casting film, etc. or magnetron sputtering, electron beam evaporation, heat evaporation, electrochemistry Deposition, chemical vapor deposition, atomic force deposition, sol gel technique, etc. form the first optical structural layer or the second optical structure layer, a dielectric layer, or the like, and is not limited thereto.

[0103] Further, the preparation method of the colorful electrochromic structure includes:

[0104] A substrate is provided; a method of depositing a first optical structural layer or a second optical structuring layer is deposited on the substrate, and a medium layer is deposited on the first optical structural layer or a second optical structure layer; Different layers are deposited according to requirements.

[0105] Further, the method of deposition of the PVD includes thermal sanding, ...

Embodiment 1

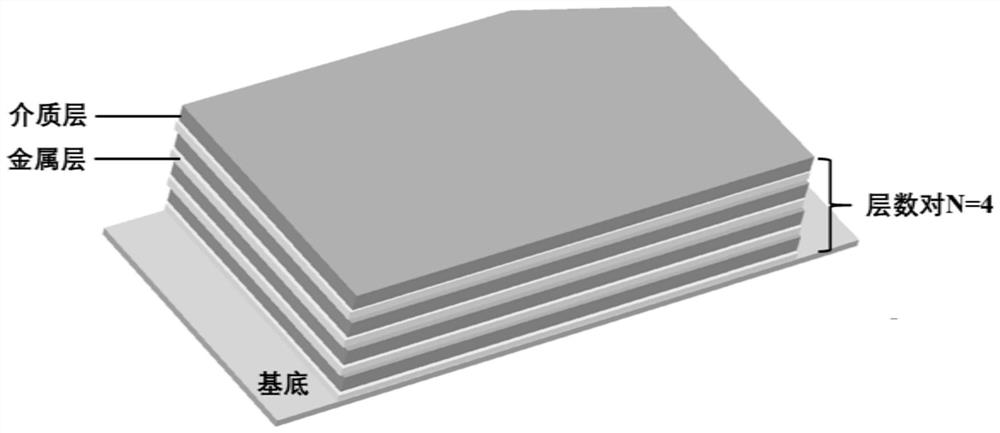

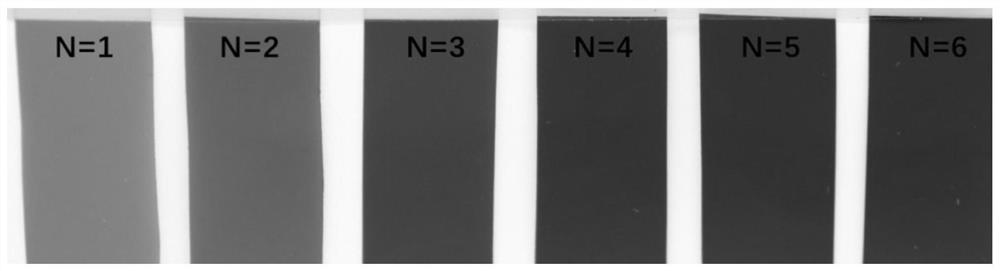

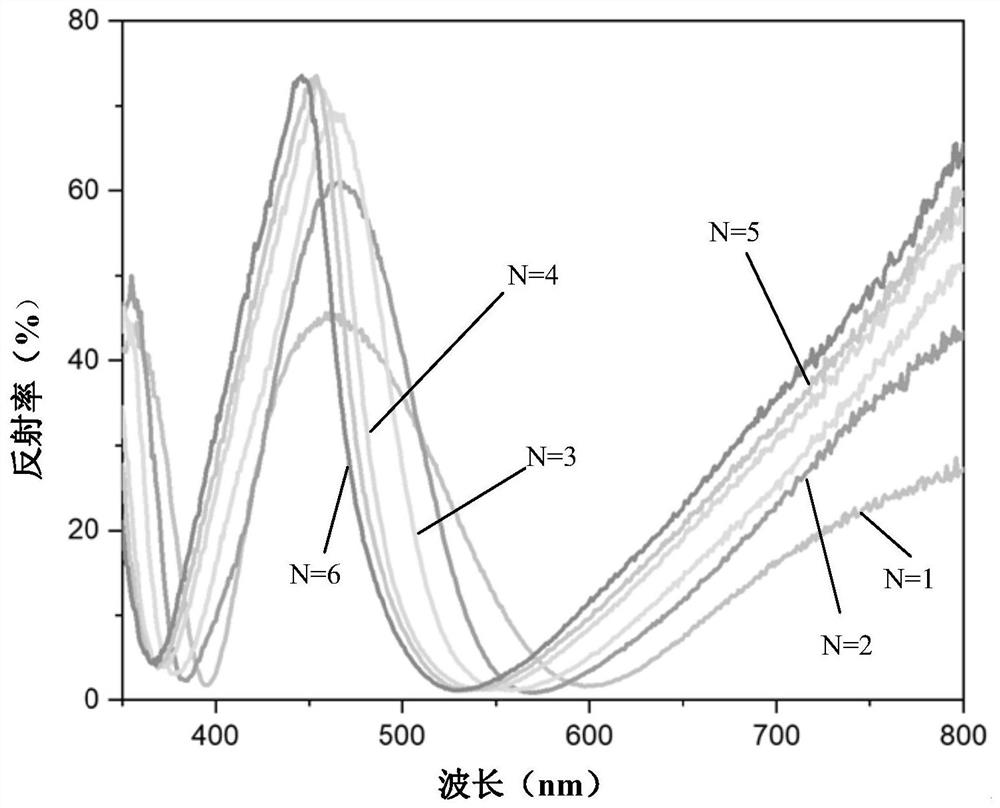

[0155] The preparation process of a multicolor, saturation, and purity of the present embodiment (may also be referred to as a colorful film) is as follows: in a clean PET substrate, a method of magnetron sputtering is deposited Layer W layer, thickness of about 10 ~ 30 nm; again in metal W layer, magnetron sputter one layer WO 3 The layer, the thickness is about 150 to 250 nm; the number of cycles can be obtained according to different requirements, and a colorful film of different layers to N = 2 to 6 (principle N ≥ 2) can be obtained. See figure 1As shown, the multicolored electrochromic film of the present embodiment includes a substrate, a metal layer, a dielectric layer, a metal layer, and a dielectric layer, which constitutes a metal-dielectric structure, which can generate optical multilayer film interference, thereby displaying colourful. figure 2 The real map of the colorful film is shown.

[0156] Of course, the aforementioned metal W layer can also be prepared using an...

Embodiment 2

[0160] The preparation process of a multi-color electrochromic film of the present embodiment disclosed is as follows: In the clean glass substrate, the desired pattern is obtained using a mask, and a layer is deposited by magnetron sputtering. The metal W layer, the thickness is about 10 ~ 30 nm; then the magnetron sputtering of the metal W layer is first WO 3 The layer, the thickness is about 150 to 250 nm; the number of cycles can be obtained according to different requirements, and a colorful film of different layers to N = 2 to 6 (principle N ≥ 2) can be obtained.

[0161] Of course, the aforementioned metal W layer can also be prepared using an electron beam evaporation, thermal plating. WO 3 The layer can be prepared by electron beam evaporation, thermurally plating, electrochemical deposition, and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com