Hot isostatic pressure repair process for connection interface of tungsten-chromium zirconium copper vacuum brazing part

A hot isostatic press, chromium zirconium copper technology, applied in welding equipment, manufacturing tools, non-electric welding equipment and other directions, to achieve the effect of improving yield, improving stability and firmness, and repairing interface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

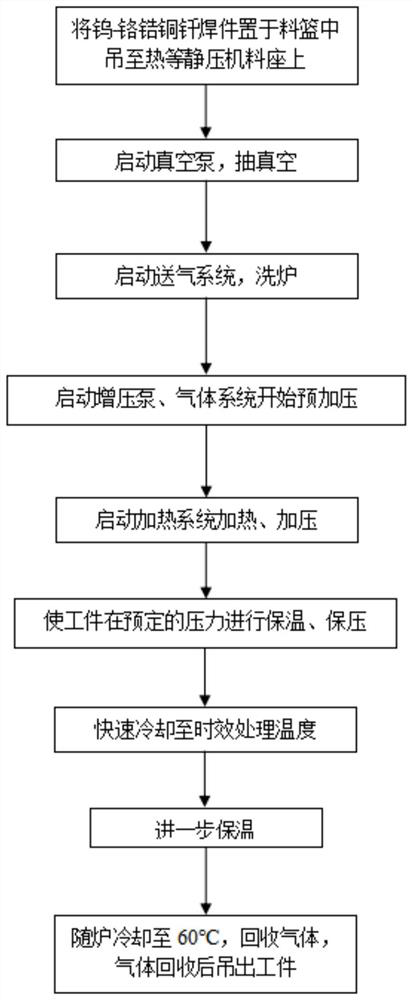

[0032] Please refer to figure 1 , the present embodiment provides a tungsten-chromium-zirconium-copper vacuum brazing joint interface hot isostatic pressing repair process, including the following steps:

[0033] Place the tungsten-chromium-zirconium copper vacuum brazing parts in the hot isostatic press basket, and place them on the material seat of the hot isostatic press;

[0034] Start the hot isostatic press and start vacuuming, the vacuum degree is 100Pa;

[0035] Start the gas supply system to clean the furnace and deflate the gas. The purity of the gas is not less than 99.99% argon. replaced;

[0036] Start the supercharger to start pre-increasing, the pre-increasing parameter is 45MPa; the pre-increasing is because the pressure of the gas will increase with the temperature during the heating process, and the pressure will increase, so generally some pressure will be pre-increased, When the temperature is up, if the pressure is not enough, add a little more pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com