Orthopedic 3D printing method and device based on AI

A 3D printing and orthopedic technology, applied in the field of 3D printing, can solve the problems of inability to build a 3D model of damaged human tissue, lack of it, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

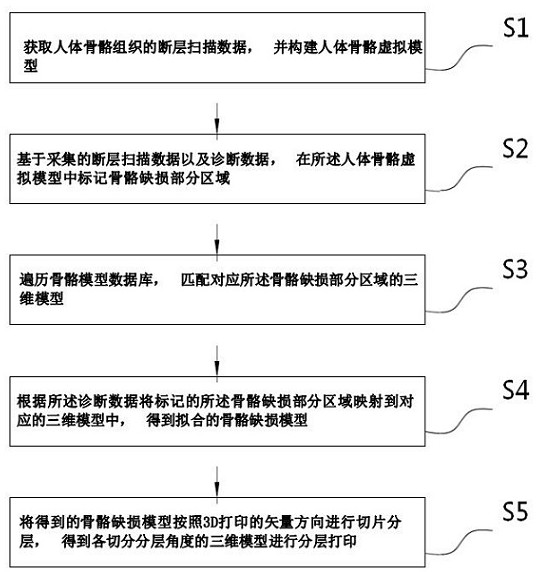

[0072] refer to figure 1 as shown, figure 1 A flow chart of an AI-based orthopedic 3D printing method provided in this application. One embodiment of the present application provides an AI-based orthopedic 3D printing method, comprising the following steps:

[0073] S1: Obtain tomographic data of human bone tissue, and construct a virtual model of human bone.

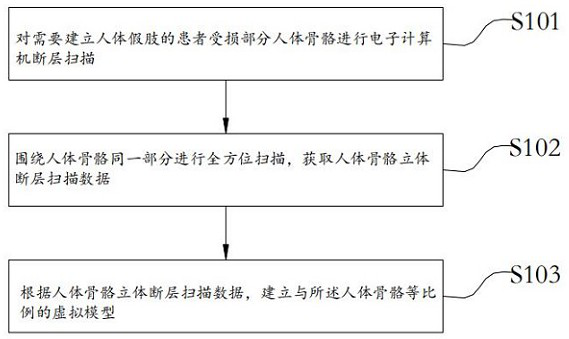

[0074] When constructing a virtual model of human skeleton, see figure 2 As shown, the acquisition method of the tomographic data is:

[0075] S101, performing computerized tomography scanning on the damaged part of the human skeleton of the patient who needs to establish a human prosthesis;

[0076] S102. Carry out an all-round scan around the same part of the human skeleton, and obtain the three-dimensional tomographic data of the human skeleton;

[0077] S103. According to the three-dimensional tomographic data of the human skeleton, establish a virtual model with the same proportion as the human skeleton.

[...

Embodiment 2

[0123] see Figure 7 As shown, an embodiment of the present application provides an AI-based orthopedic 3D printing device, including a bone virtual model building module 100, a defect area marking module 200, a three-dimensional model matching module 300, a bone defect model fitting module 400, and a 3D Print module 500 . in:

[0124] The skeleton virtual model construction module 100 is used for constructing a human skeleton virtual model according to the acquired tomographic image data.

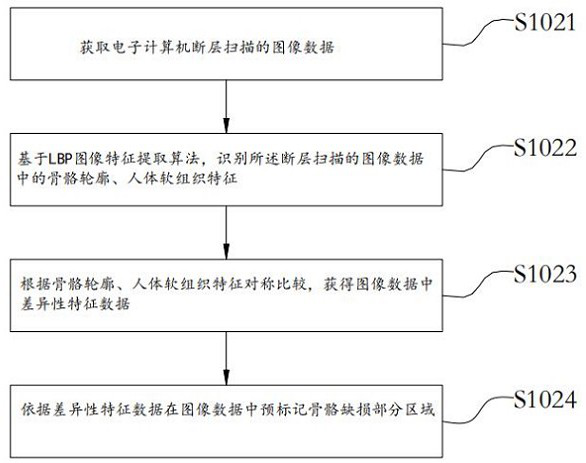

[0125] When constructing the virtual model of the human skeleton, by obtaining the image data of the electronic computer tomography, based on the LBP image feature extraction algorithm, identify the bone outline and human soft tissue features in the tomographic image data, according to the symmetry of the bone outline and human soft tissue features Compare to obtain the difference feature data in the image data.

[0126] The constructed virtual model of the damaged human skeleton is a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com