System and method for improving primary frequency modulation performance of reheating unit

A technology for reheating units and thermal systems, applied to mechanical equipment, steam engine devices, engine components, etc., can solve the problems of volume inertia delay in reheating systems, achieve short paths, low cost, and improve the performance of primary frequency regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 of the present disclosure introduces a system for improving the primary frequency regulation performance of a reheat unit.

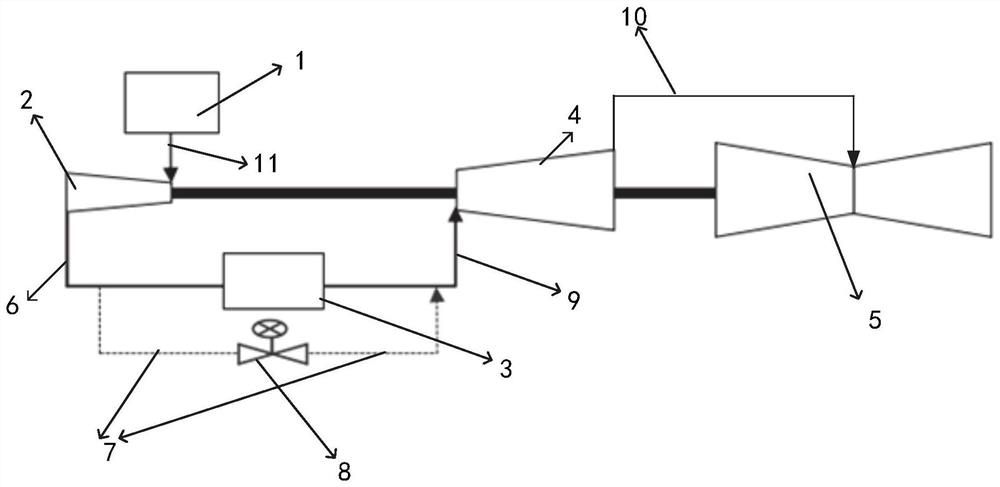

[0044] Such as figure 1 A system for improving the performance of primary frequency regulation of reheating units is shown, including superheater 1, high-pressure cylinder 2, reheater 3, medium-pressure cylinder 4, low-pressure cylinder 5, reheat system cold section steam main pipe 6, reheat Steam bypass pipe 7, regulating valve 8, steam main pipe 9 in the hot section of the reheating system, connecting pipe 10 and main steam main pipe 11 of the unit.

[0045] As one or more implementations, the cold section pipeline 6 of the reheat system is used to connect the high pressure cylinder 2 and the reheater 3 , and the hot section pipeline 9 of the reheat system is used to connect the reheater 3 and the medium pressure cylinder 4 .

[0046] As one or more implementations, one side of the high-pressure cylinder 2 is connected to the super...

Embodiment 2

[0051] Embodiment 2 of the present disclosure introduces a method for improving the primary frequency regulation performance of a reheating unit.

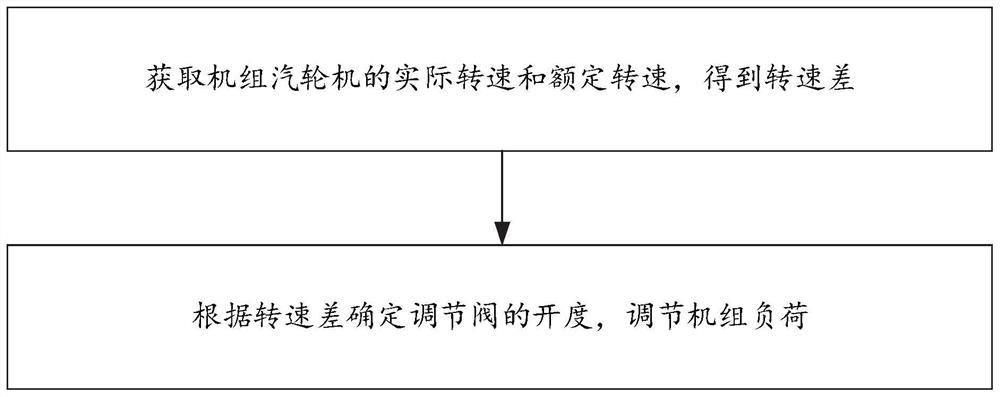

[0052] Such as figure 2 A method for improving the primary frequency regulation performance of the reheating unit shown includes the following steps:

[0053] Obtain the actual speed and rated speed of the steam turbine of the unit, and obtain the speed difference;

[0054] Determine the opening of the regulating valve according to the speed difference to adjust the load of the unit

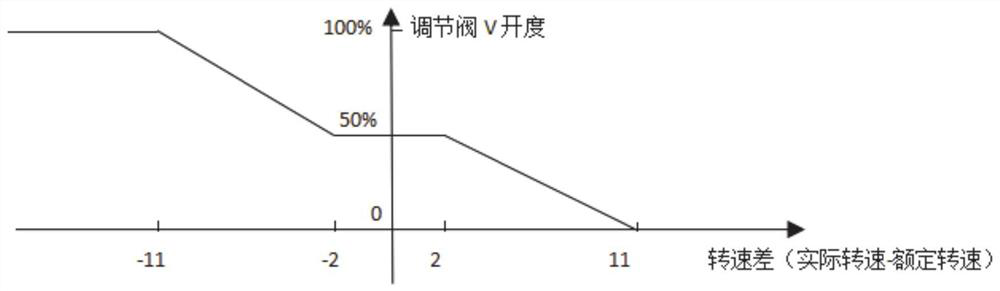

[0055]As one or more implementations, according to the maximum load variation of primary frequency regulation is 6% of rated power, the capacity of the reheat steam bypass system can be designed according to 12% of the rated flow of reheat steam.

[0056] The control logic of the reheat steam bypass flow regulating valve V is added to the DCS, and the opening of V is a schematic diagram of the function relationship of the steam turbine speed differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com