Power transmission line tower surface defect detection method and device based on green laser imaging

A transmission line, laser imaging technology, applied in optical testing flaws/defects, camera devices, radio wave measurement systems, etc. The effect of non-destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

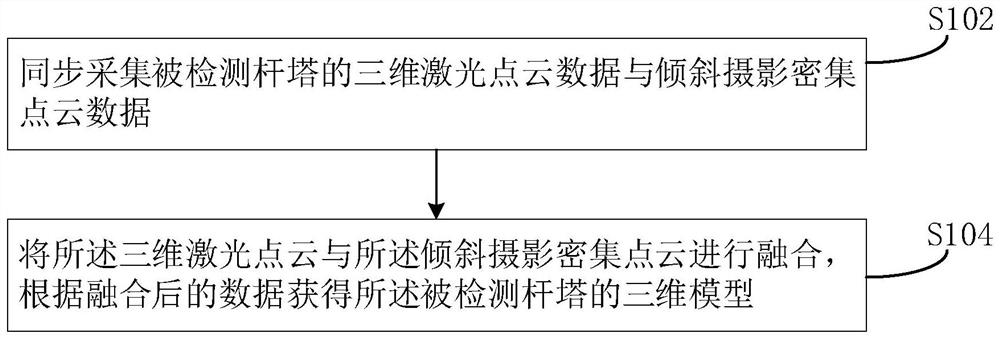

[0049] Such as figure 1 As shown, the embodiment of the present disclosure provides a laser imaging-based transmission line tower modeling method, which specifically includes the following steps:

[0050] Step S102, synchronously collecting 3D laser point cloud data and oblique photography dense point cloud data of the detected tower;

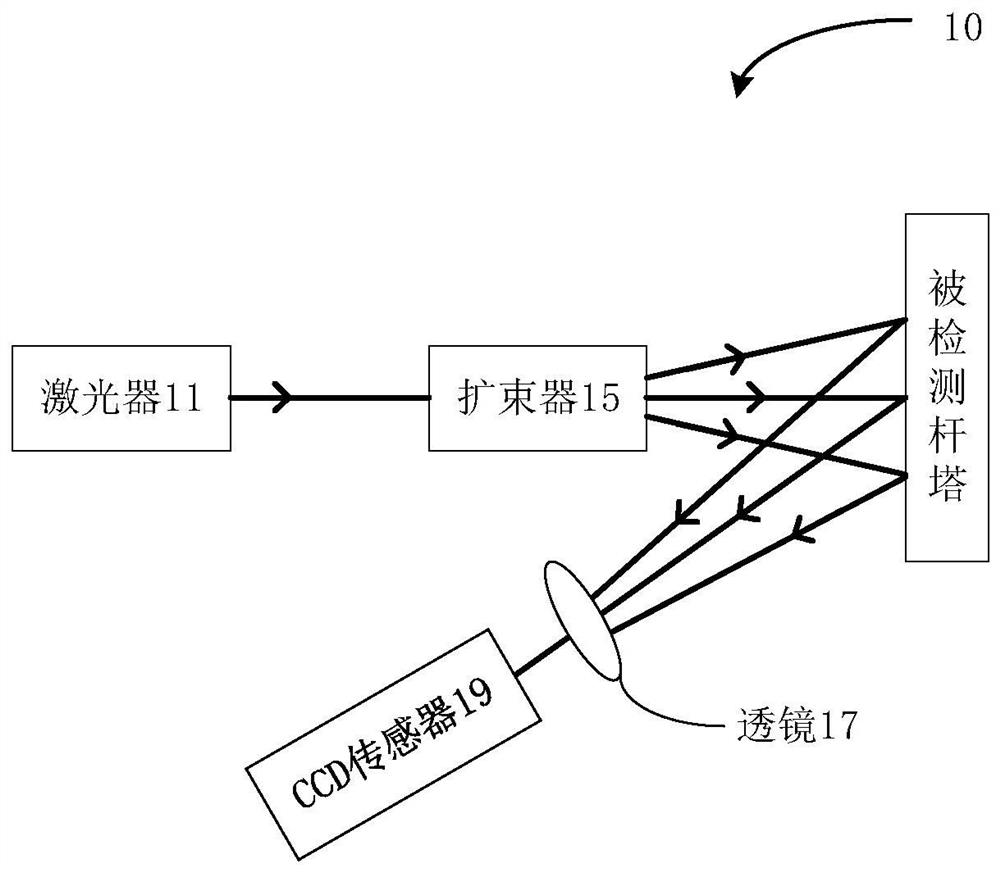

[0051] In this step, the 3D laser point cloud of the detected tower can be collected using a laser imaging system. figure 2 A schematic structural diagram of a laser imaging system 10 that can be used in this embodiment is shown.

[0052] The laser imaging system 10 includes: a laser 11 , a beam expander 15 , a lens 17 and a CCD sensor 19 . The laser beam emitted by the laser 11 is expanded by the beam expander 15 to become uniform divergent light, and the uniform divergent light and scattered light are finally imaged to the CCD sensor 19 through the lens 17 . Specifically, the laser 11 is used to generate detection light; the beam expander...

Embodiment 2

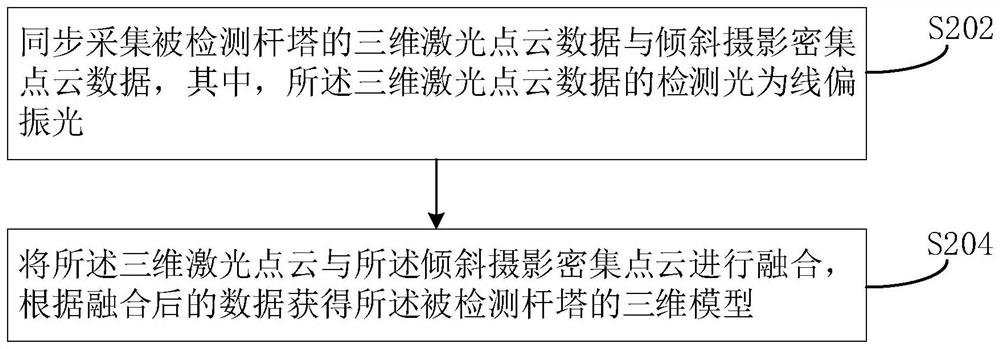

[0069] Such as image 3 As shown, the embodiment of the present disclosure also provides a method for modeling transmission line towers based on polarization laser imaging, which specifically includes the following steps:

[0070] S202. Synchronously collect 3D laser point cloud data and oblique photography dense point cloud data of the detected tower, wherein the detection light of the 3D laser point cloud data is linearly polarized light;

[0071] S204. Fusion the 3D laser point cloud data and the oblique photography dense point cloud data, and obtain a 3D model of the detected tower according to the fused data.

[0072] Different from the foregoing embodiments, linearly polarized light is used as the detection light of the three-dimensional laser point cloud data in this embodiment. Figure 4 A schematic structural diagram of a laser imaging system 20 that can be used in this embodiment is shown.

[0073] The laser imaging system 20 includes: a laser 11 , a polarizer 13 ,...

Embodiment 3

[0078] Such as Figure 5 As shown, the embodiment of the present disclosure also provides a method for modeling transmission line towers based on laser imaging, which specifically includes the following steps:

[0079] S302. Synchronously collect 3D laser point cloud data and oblique photography dense point cloud data of the detected tower, wherein the observation position of the 3D laser point cloud data is located on the ground near the detected tower, and the oblique photography dense point cloud The observation position point of the data is located in the air near the detected tower;

[0080] S304. Fusion the 3D laser point cloud data and the oblique photography dense point cloud data, and obtain a 3D model of the detected tower according to the fused data.

[0081] Different from the previous embodiments, the observation position of the three-dimensional laser point cloud data in this embodiment is located on the ground near the detected tower, while the observation posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com