Tobacco leaf field harvesting device

A tobacco leaf and field technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as low efficiency, and achieve the effects of improving harvesting efficiency, easy promotion and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

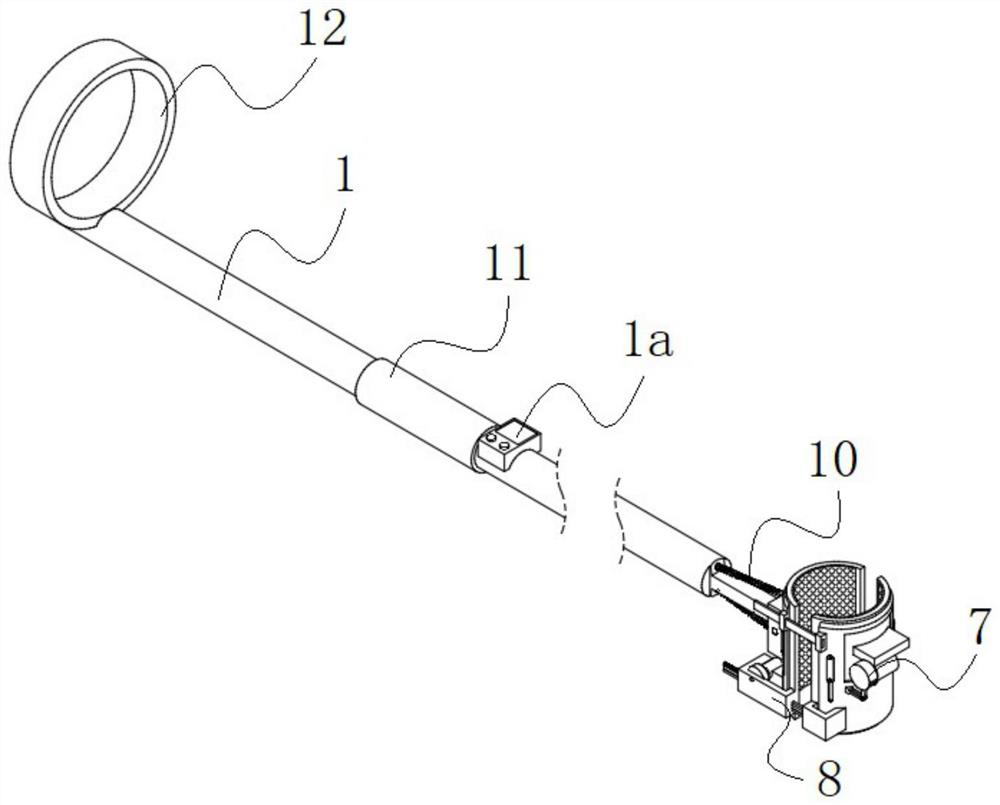

[0084] Before using the tobacco leaf field harvesting device with the above-mentioned design structure, the finished harvesting device needs to be transported to a designated working position by manual or corresponding transport equipment for use.

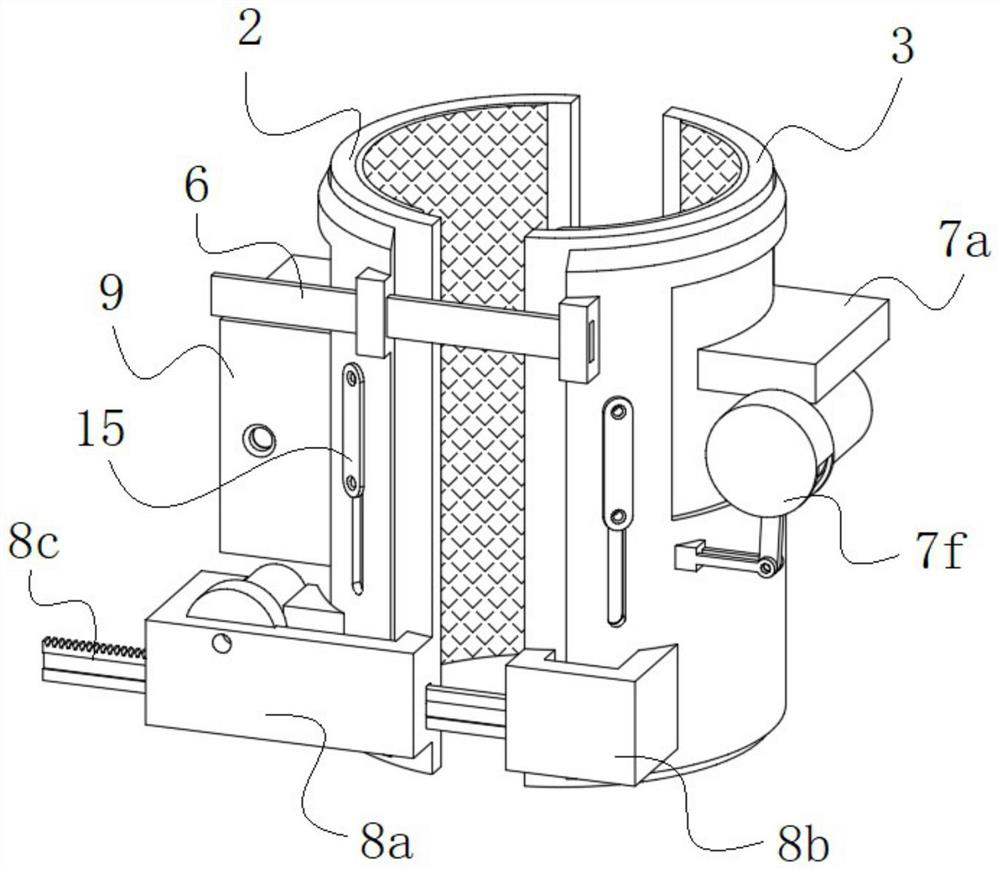

[0085] When used, such as Figure 4 As shown, the user only needs to put his arm through the collar 26, hold the handle 11 with his hand, and move the first splint 2 and the second splint 3 through the operating rod 1, so that the two first splint 2 and the second splint 3 Move to the bottom of the tobacco leaf plant to be harvested, move the first clamping plate 2 and the second clamping plate 3 so that the first clamping plate 2 and the second clamping plate 3 are placed on the surface of the tobacco leaf plant, and the first motor 8f drives the gear 8g to rotate, and the gear 8g drives the two first splints 2 and the second splint 3 to be clamped on the surface of the tobacco plant through the rack 8c, the first fixed frame 8a a...

Embodiment 2

[0088] Before using the tobacco leaf field harvesting device with the above-mentioned design structure, the finished harvesting device needs to be transported to a designated working position by manual or corresponding transport equipment for use.

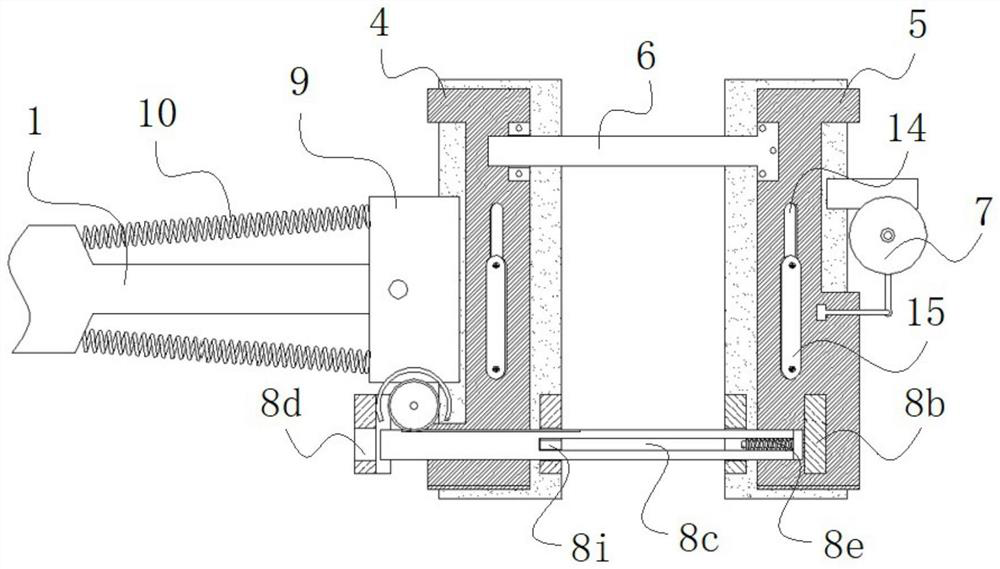

[0089] The design structure of this embodiment 2 is basically the same as that of embodiment 1, the only difference is that the blades of the first cutting knife 4 and the second cutting knife 5 are downward and the design of parts on the lifting control mechanism 7 is different. The specific implementation process is as follows:

[0090]When used, such as Figure 5 to Figure 8 As shown, the user only needs to put his arm through the collar 26, hold the handle 11 with his hand, and move the first splint 2 and the second splint 3 through the operating rod 1, so that the two first splint 2 and the second splint 3 Move to the bottom of the tobacco leaf plant to be harvested, move the first clamping plate 2 and the second clamping pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com