Method for improving smoke quality of air-cured tobacco

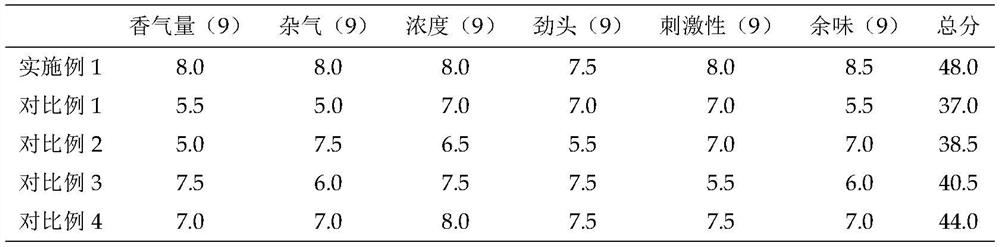

A technology for air-drying tobacco and flue gas, which is applied in the field of tobacco, and can solve the problems of insufficient smoke aroma and aroma, failure to meet quality requirements, and insufficient purity of the aftertaste, and achieve the effect of sufficient aroma, pure aftertaste, and less miscellaneous gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) After the fresh tobacco leaves are fully aired, turned yellow and fixed, the color is removed from the shelf, so that the water content of the tobacco leaves is 11wt%; put into the characteristic extract of Artemisia annua obtained above and soak for 30 minutes;

[0033] (2) Add the soaked tobacco leaves to the rice wine fermentation liquid, and the natural fermentation time is 2 days at 90°C;

[0034] (3) airing the tobacco leaves after fermentation for 10 days again, so that the moisture content of the tobacco leaves is 15wt%;

[0035] (4) The air-dried tobacco leaves are put into storage for natural aging and aging for 30 days, the relative air humidity is 50%, and the temperature is 30°C; the air-dried tobacco is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com