Frame and frame integrated RAT system

An integrated, frame-based technology, applied in the direction of auxiliary power equipment, aircraft parts, transportation and packaging, etc., can solve the problems of large volume, difficult manufacturing, heavy weight, etc., and achieve simple interface, reduce overall weight, and difficult processing low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

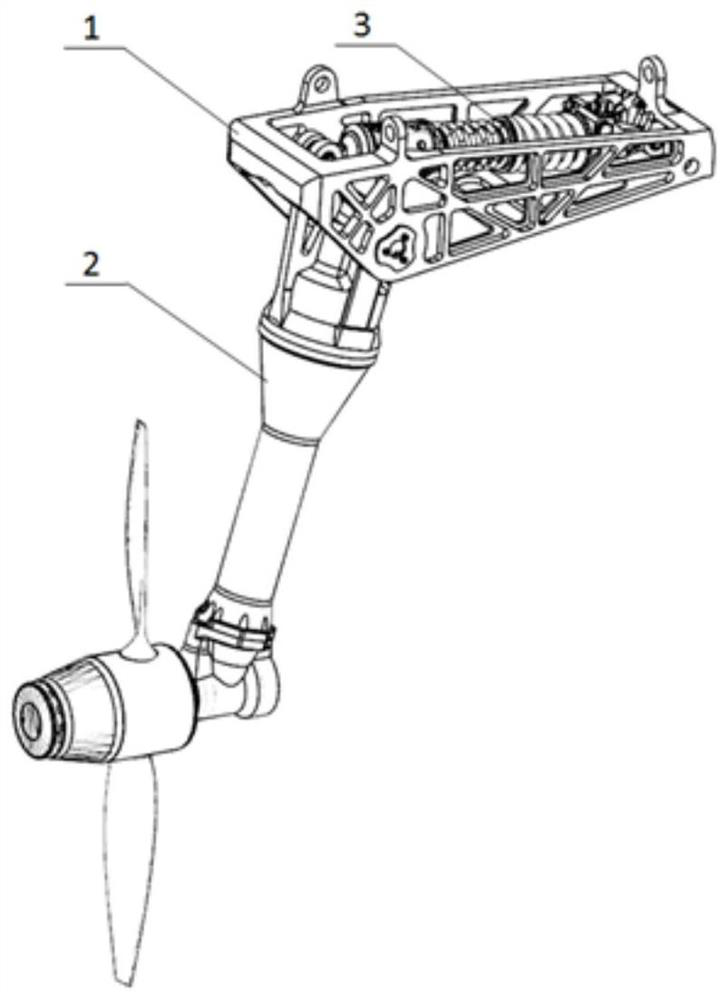

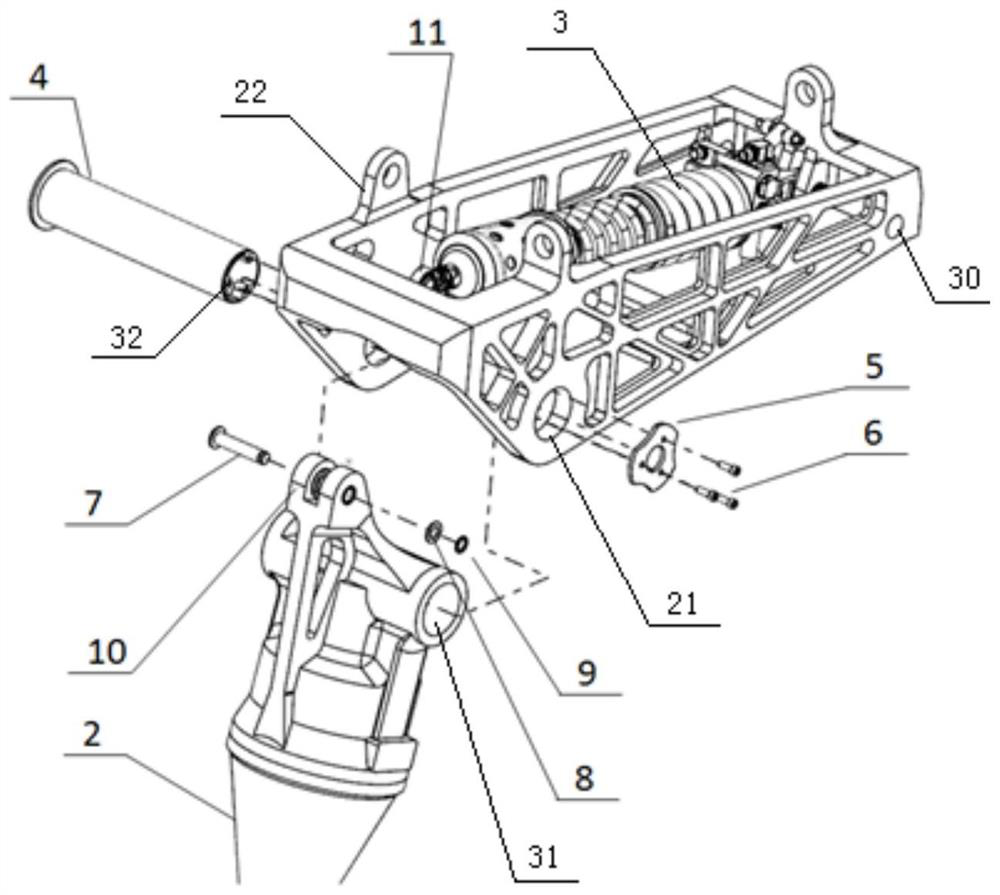

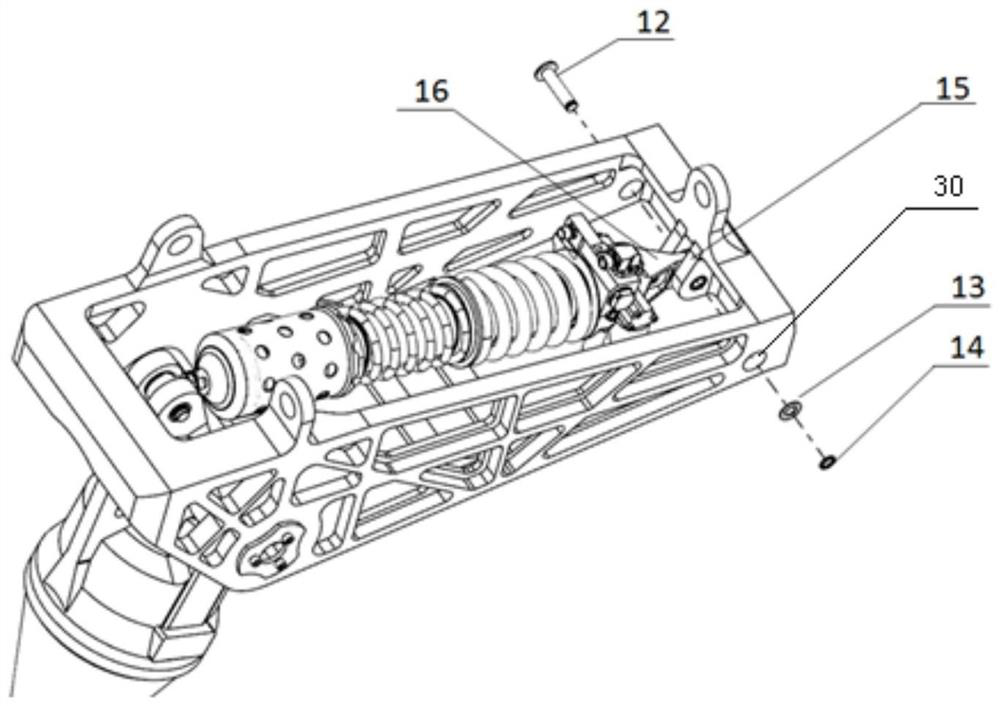

[0029] Example 1. A frame-integrated RAT system, constituted as Figure 1-5 As shown, it includes a pair of frame plates 20 arranged in parallel. The overall shape of the frame plates 20 is an inverted triangle shape. The top corners of the head ends of the two frame plates 20 are connected by the front beam 17. Connected through the lower beam 19, the top corners of the tail ends of the two frame plates 20 are connected through the tail beam 18; the bottom corners of the two frame plates 20 are provided with a coaxial pivot center hole 21; the middle part of the tail beam 18 is provided with Tail beam hanging point interface 15; the frame is integrally formed, and the top of the frame is provided with three aircraft hanging points 22 connected with the aircraft. The one-piece molding is made by 3D printing, which is convenient for the field to replace as a whole, and compared with the one-piece casting, it has higher strength.

[0030] The aforementioned lower beam 19 is pr...

Embodiment 2

[0040] Example 2. A frame-integrated RAT system, such as figure 1 As shown, it consists of a frame 1, a ram air turbine 2 and a retractable actuator 3, wherein the frame 1 is an integrated structure manufactured by 3D printing. Such as figure 2 As shown, the ram air turbine 2 is mounted on the frame 1 through a pivot 4, a retaining ring I5 and three screws 6. Such as image 3As shown, the tail boom 18 is integrated with the tail boom hanging point interface 15 of the retractable actuator tailstock 16, and the tailstock 16 of the retractable actuator 3 is connected to the tail boom through the pin shaft II12, the washer II13 and the retaining ring III14 On the hanging point interface 15. Such as figure 2 As shown, the ram air turbine 2 is designed with a front seat hanging point interface 10 connected to the front seat of the retractable actuator, and the front seat 11 of the retractable actuator 3 is connected to the front seat hanging point interface through the pin s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com