Electrical cabinet automatic inspection system based on infrared temperature measurement imaging

An infrared temperature measurement and automatic inspection technology, applied in electrical components, transmission systems, temperature recording methods, etc., can solve the problems of easy breakage of optical fibers, complicated installation, difficult wiring, etc., to reduce potential safety hazards, improve inspection efficiency, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

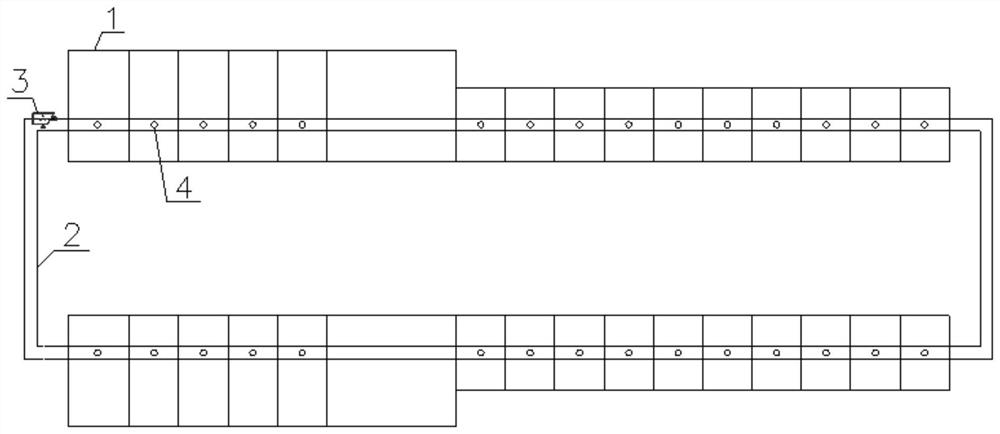

[0035] Such as figure 1 and figure 2 As shown, the automatic inspection system for electrical cabinets based on infrared temperature measurement and imaging includes infrared thermal imaging cameras 3 .

[0036] The infrared thermal imaging camera 3 is arranged on a terminal platform capable of moving along the preset guide rail 2;

[0037] The preset guide rail 2 is set around a plurality of electrical cabinets 1 that need to be inspected, forming a circular track that can circle around a plurality of electrical cabinets 1;

[0038] There is a lifting device on the intelligent platform;

[0039] The lifting device is used to lift the infrared thermal imaging camera 3 to a height corresponding to the infrared transmission window 4 of each electrical cabinet 1;

[0040] Both the terminal platform and the infrared thermal imaging camera 3 are connected to the monitoring cloud platform by wired or wireless means, send the current working status to the monitoring cloud platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com