Weld joint toughness evaluation method

An evaluation method and toughness technology, which is applied in the field of weld toughness evaluation, can solve the problems of low accuracy and achieve the effects of improving accuracy, improving evaluation efficiency, and shortening the evaluation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

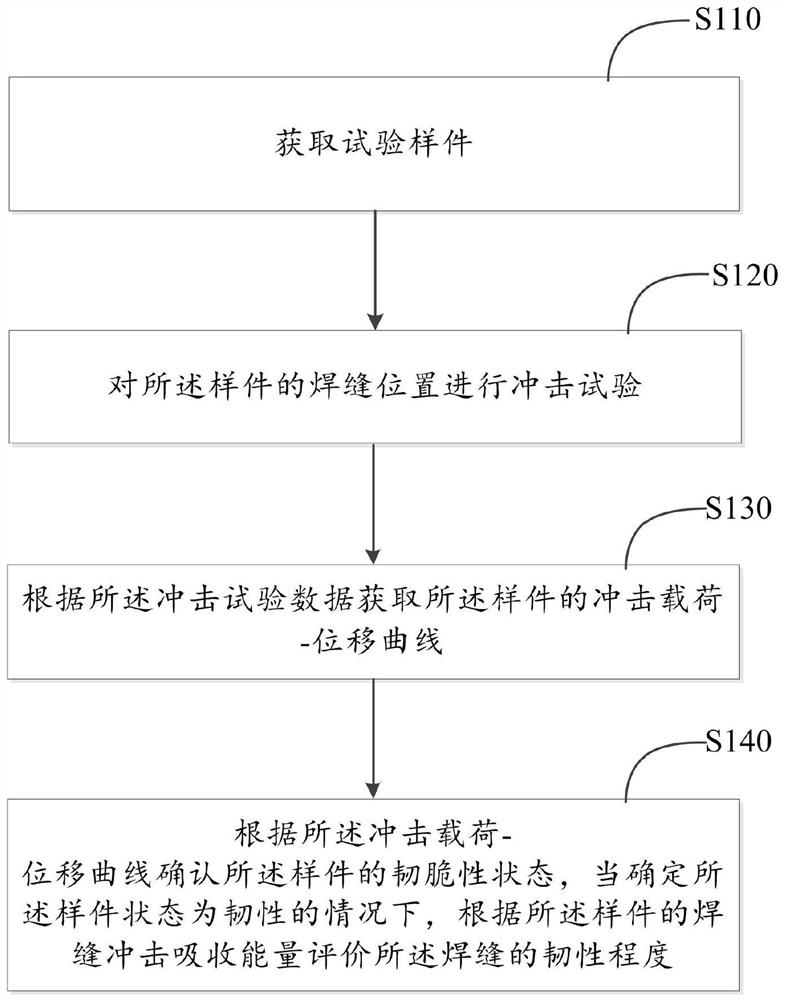

[0048] see figure 1 , is a schematic flow chart of a method for evaluating the toughness of a weld 210 provided in the embodiment of the present application, which may specifically include:

[0049] S110, obtaining the test sample 200;

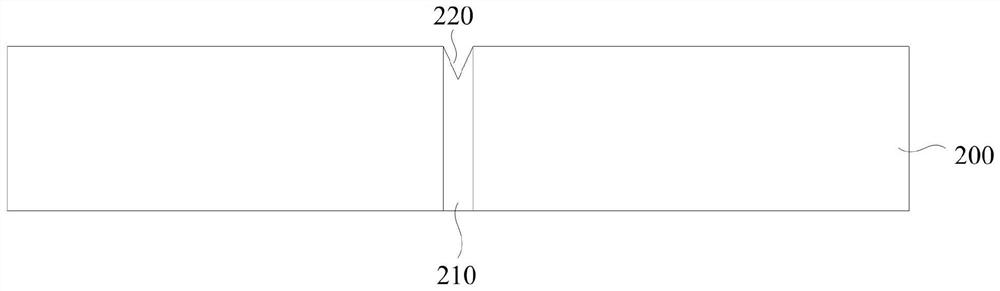

[0050] Specifically, the material of this application is a thermoformed tailor-welded blank, and a test sample 200 is obtained from the thermoformed tailor-welded blank, and the test sample 200 includes a weld 210;

[0051] S120, performing an impact test on the position of the weld 210 of the sample 200;

[0052] Specifically, the sample 200 is placed on a testing machine, and an impact test is performed on the position of the weld 210 of the sample 200. The testing machine can be a pendulum impact testing machine. The testing range of the pendulum impact testing machine is 25J and 50J, and the pendulum impact testing machine with a testing range of 50J can be used for tough materials.

[0053] Exemplarily, the testing machine can be a zwi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com