Method for building laser spot homogenization system for fiber laser and system

A fiber laser and laser spot technology, applied in the field of space optical target simulation, can solve the problems of poor stability, complex system structure, unfavorable laser spot homogenization design, etc., and achieve the effects of good stability, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

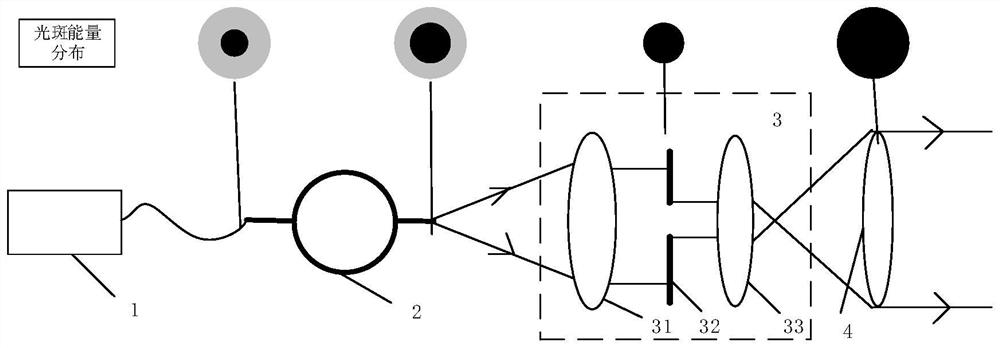

[0039] Such as figure 1 As shown, the present invention is a laser spot homogenization system for fiber lasers, the main working principle is: the fiber laser emits laser light through the pigtail, and passes through the homogenization optical fiber (the homogenization optical fiber adopted in this embodiment is a square-core optical fiber) ) for energy homogenization, so that the original energy distribution of the spot is disrupted, but due to the limitations of the device, the energy uniformity is not high, so the "apodizer" (lens system) is used to achieve high homogenization requirements. The straight lens can realize the collimation of the beam, select the beam that meets the uniformity requirements through the diaphragm, and then complete the focusing of the beam through the focusing lens, and finally complete th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com