Catalyst with low Pt loading capacity as well as preparation method and application thereof

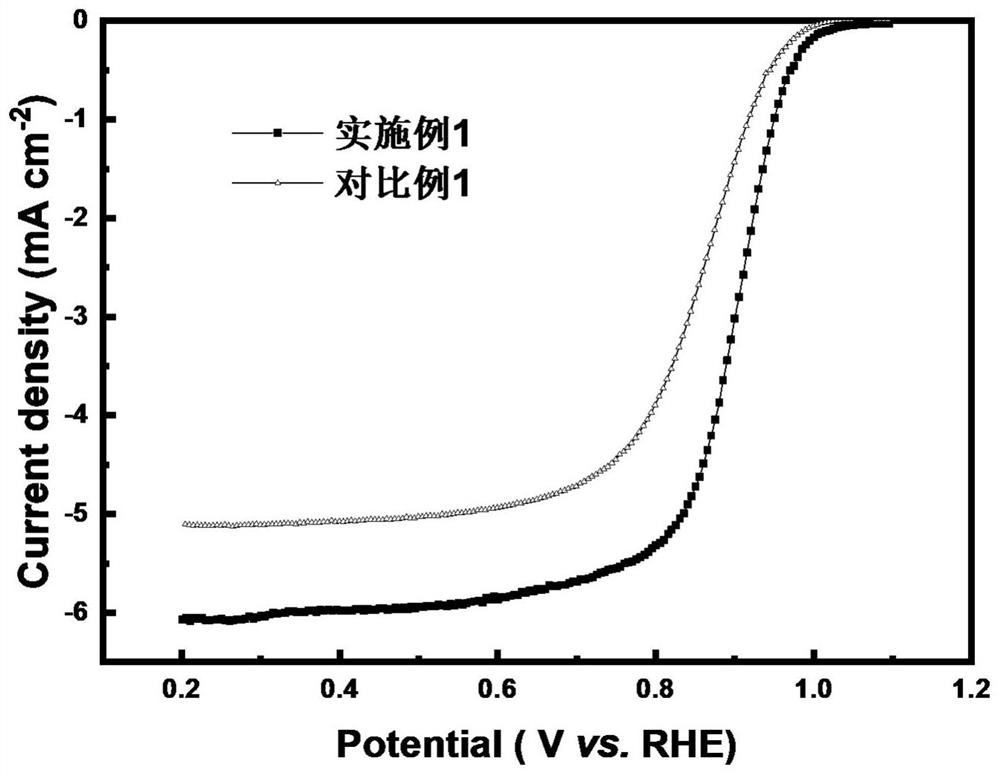

A catalyst and loading capacity technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of Pt nanoparticle agglomeration and complicated process, and achieve the effects of reducing costs, excellent ORR activity, and improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a catalyst with a low Pt load, comprising the following steps:

[0027] Preparation of Fe-N-C catalyst carrier: weigh 2.2g Zn(NO 3 ) 2 ·6H 2 O, 0.2g Fe(NO 3 ) 3 9H 2 O was dissolved in 100ml of anhydrous methanol, ultrasonically mixed for 20min, and recorded as solution A. Weigh 2.5g of 2-methylimidazole and dissolve it in 20ml of anhydrous methanol, stir for 20min, and record it as solution B. Subsequently, the solutions A and B were mixed uniformly and placed in an oil bath at 60° C. for 24 h. After the reaction was completed, it was washed twice with absolute ethanol, and dried in a vacuum oven (60° C.) for 12 hours. The dried white precursor was pyrolyzed at 1100 °C for 1 h under nitrogen atmosphere (heating rate 5 °C min -1 ), and finally the obtained catalyst product is fully ground, which is recorded as Fe-N-C catalyst carrier.

[0028] Supporting Pt and CeO on Fe-N-C Catalyst Support 2 : first disperse 100mg Fe-N-C catalyst carr...

Embodiment 2

[0030] A preparation method of a catalyst with a low Pt load, comprising the following steps:

[0031] Preparation of Fe-N-C catalyst carrier: weigh 2.2g Zn(NO 3 ) 2 ·6H 2 O, 0.2g Fe(NO 3 ) 3 9H 2O was dissolved in 100ml of anhydrous methanol, ultrasonically mixed for 20min, and recorded as solution A. Weigh 2.5g of 2-methylimidazole and dissolve it in 20ml of anhydrous methanol, stir for 20min, and record it as solution B. Subsequently, the solutions A and B were mixed uniformly and placed in an oil bath at 60° C. for 24 h. After the reaction was completed, it was washed twice with absolute ethanol, and dried in a vacuum oven (60° C.) for 12 hours. The dried white precursor was pyrolyzed at 500 °C for 1 h in an ammonia atmosphere (heating rate 5 °C min -1 ), and finally the obtained catalyst product is fully ground, which is recorded as Fe-N-C catalyst carrier.

[0032] Supporting Pt and CeO on Fe-N-C Catalyst Support 2 : first disperse 100mg Fe-N-C catalyst carrier...

Embodiment 3

[0034] A preparation method of a catalyst with a low Pt load, comprising the following steps:

[0035] Preparation of Fe-N-C catalyst carrier: weigh 2.2g Zn(NO 3 ) 2 ·6H 2 O, 0.2g Fe(NO 3 ) 3 9H 2 O was dissolved in 100ml of anhydrous methanol, ultrasonically mixed for 20min, and recorded as solution A. Weigh 2.5g of 2-methylimidazole and dissolve it in 20ml of anhydrous methanol, stir for 20min, and record it as solution B. Subsequently, the solutions A and B were mixed uniformly and placed in an oil bath at 60° C. for 24 h. After the reaction was completed, it was washed twice with absolute ethanol, and dried in a vacuum oven (60° C.) for 12 hours. The dried white precursor was pyrolyzed at 1300 °C for 1 h under an argon atmosphere (heating rate 5 °C min -1 ), and finally the obtained catalyst product is fully ground, which is recorded as Fe-N-C catalyst carrier.

[0036] Supporting Pt and CeO on Fe-N-C Catalyst Support 2 : first disperse 100mg Fe-N-C catalyst carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com