Waste gas desulfurization treatment device

A treatment device, a technology for desulfurization of waste gas, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of insufficient desulfurization, low efficiency, blockage of pores, etc., and achieve the effect of complete desulfurization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

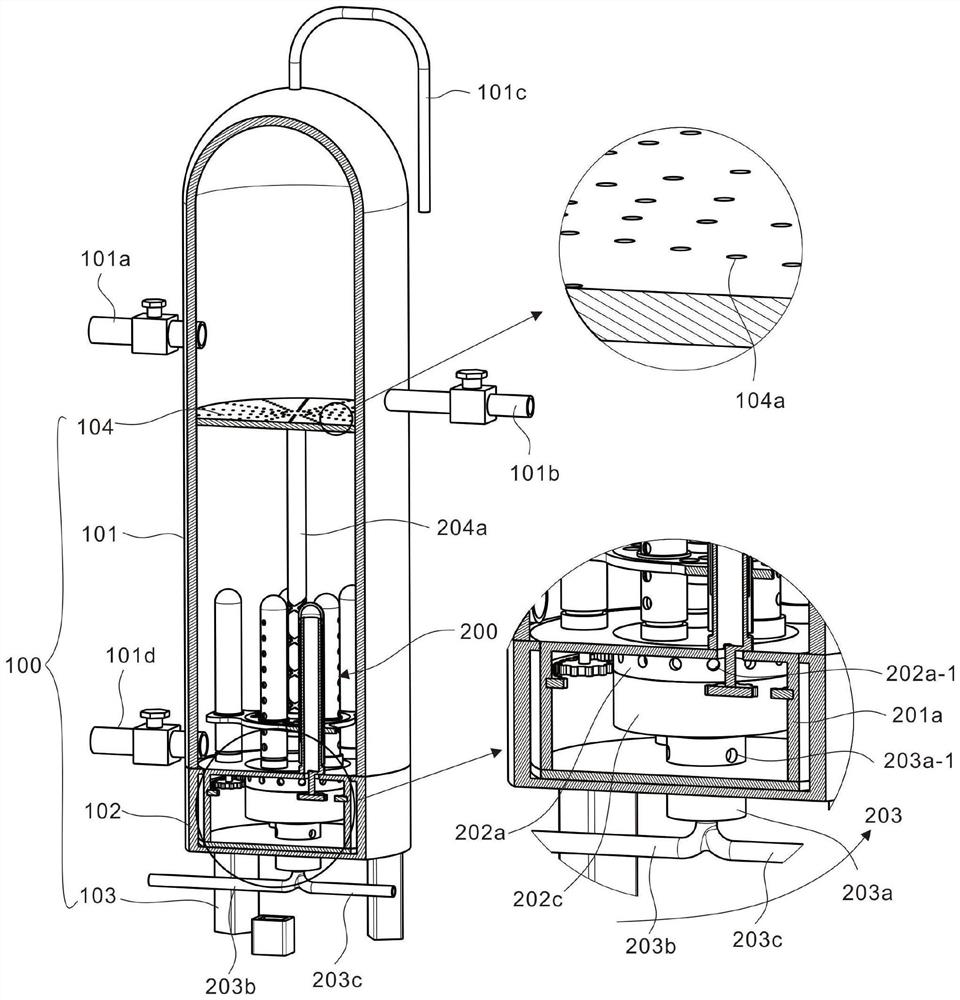

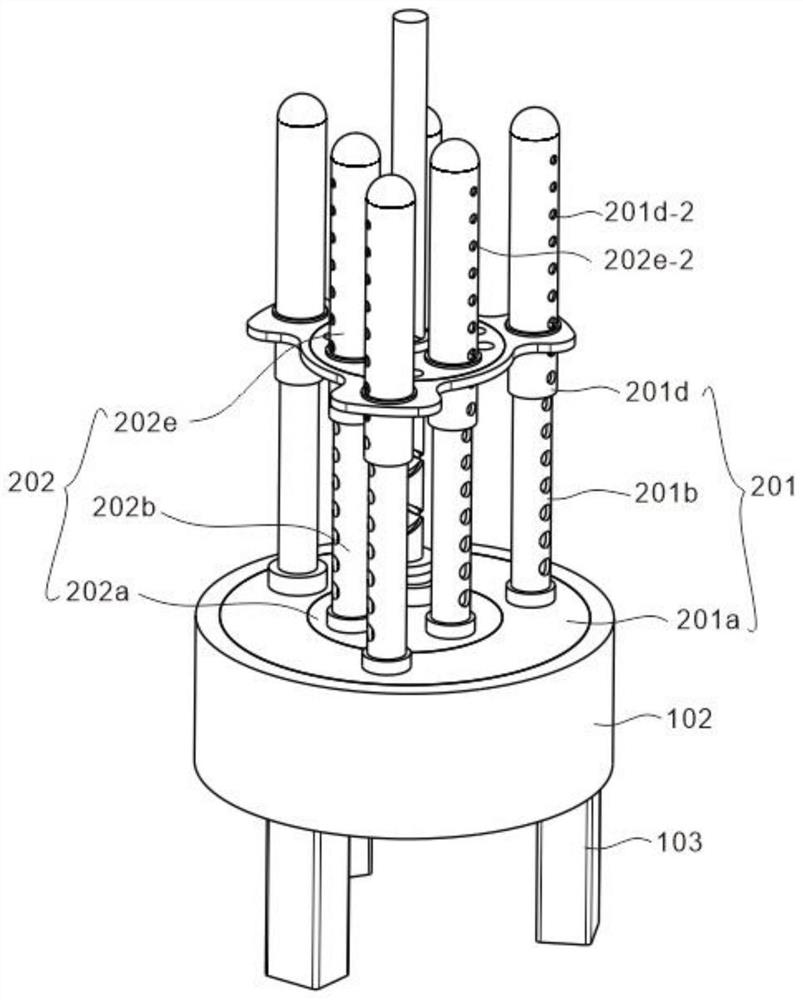

[0032] refer to Figure 1 to Figure 8 , is the first embodiment of the present invention, which provides an exhaust gas desulfurization treatment device. The exhaust gas desulfurization treatment device includes a carrying unit 100 and a processing unit 200 , and the processing unit 200 is arranged inside the carrying unit 100 .

[0033] Specifically, the bearing unit 100 includes a bearing tank 101, a base 102 sealingly connected with the bearing tank 101, a bracket 103 arranged at the bottom of the base 102, and a baffle 104 arranged at the upper half of the bearing tank 101, The baffle plate 104 is provided with an array of drip holes 104a.

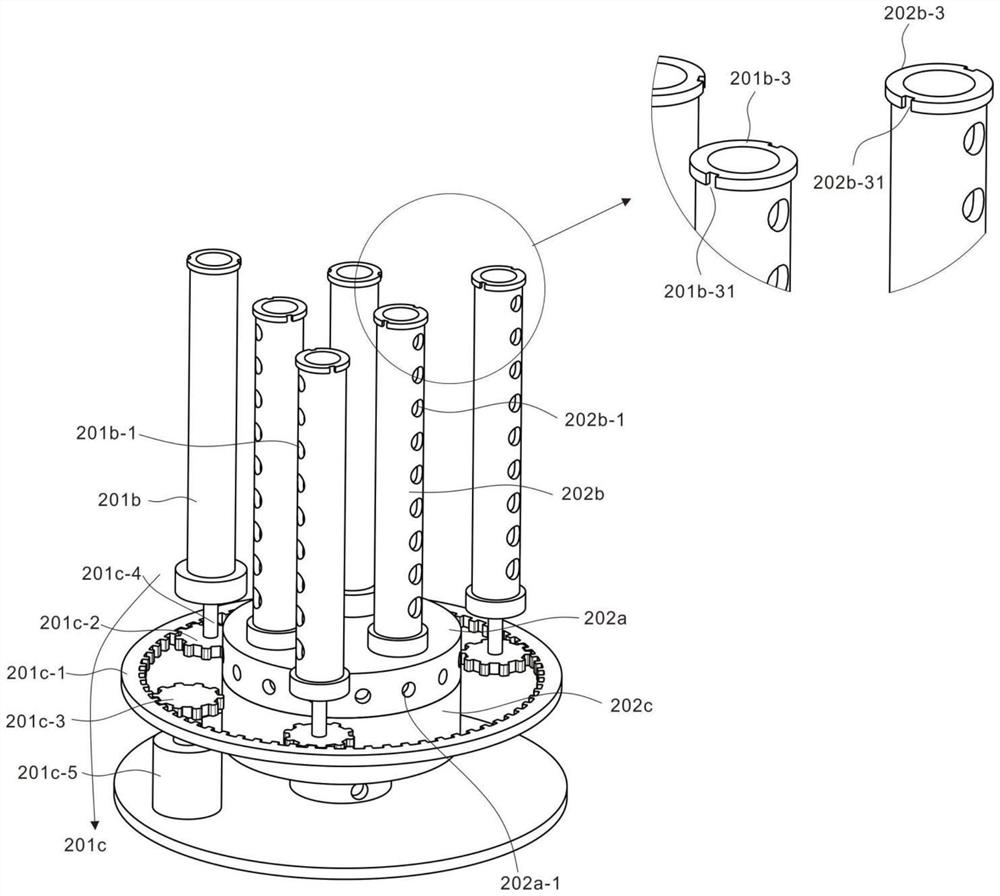

[0034] The processing unit 200 includes a first processing unit 201, a second processing unit 202, a gas supply unit 203, and a circulation lifting unit 204. The first processing unit 201 includes a first gas cylinder 201a that is rotatably engaged with the base 102 and is disposed on the second processing unit. A first gas outlet cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com