Novel assembly type airport pavement system setting method

A prefabricated, airport technology, applied in the direction of paving, roads, and road repairs paved with prefabricated blocks. The effect of improving the load transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

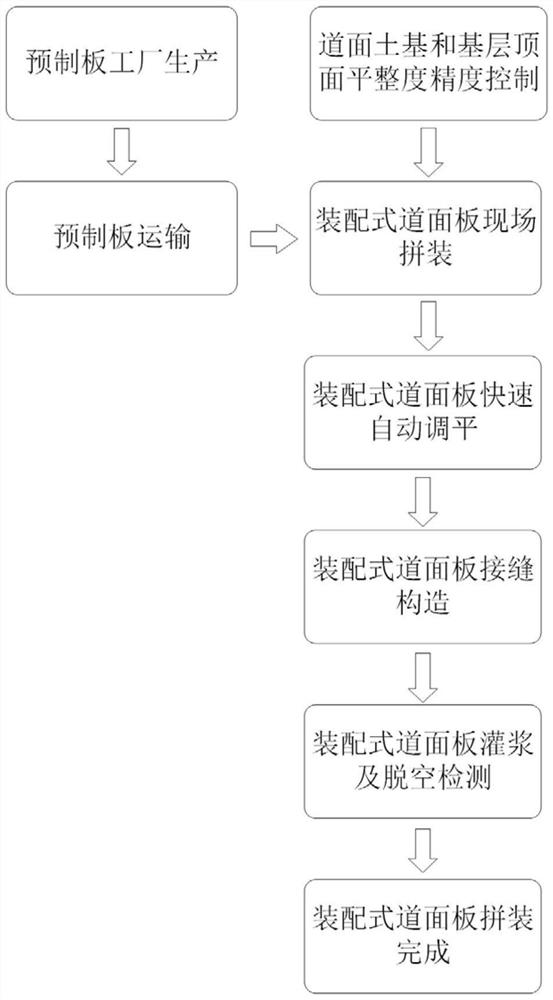

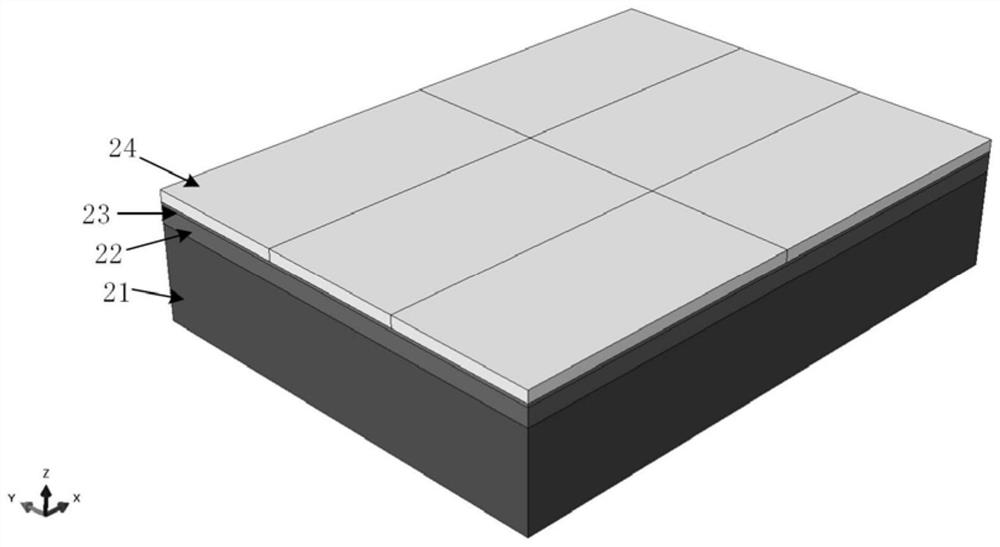

[0067] Combined with the accompanying drawings, a new type of prefabricated airport pavement system setting method. figure 2 It is a schematic cross-sectional view of the construction position of the prefabricated airport road slab, including a pavement soil foundation 21 and a base 22 arranged on the pavement soil foundation. Through the control method of the flatness accuracy of the pavement soil foundation and the top surface of the base, the production method of the prefabricated pavement panel prefabrication factory, the on-site assembly method of the prefabricated pavement pavement, the fast and automatic leveling method of the prefabricated pavement pavement, and the seaming method of the prefabricated pavement pavement , Prefabricated pavement grouting and void detection method, prefabricated pavement rapid replacement method, to achieve accurate and rapid installation, replacement and maintenance of the overall structure of the airport pavement.

Embodiment 2

[0069] The new prefabricated airport pavement system and method, through the precision control method of the road surface soil foundation and the top surface of the base, the production method of the prefabricated pavement panel prefabrication factory, the on-site assembly method of the prefabricated pavement pavement, and the rapid and automatic leveling of the prefabricated pavement pavement The method, the seaming method of the prefabricated pavement, the grouting and void detection method of the prefabricated pavement, and the rapid replacement method of the prefabricated pavement realize the accurate and rapid installation, replacement and maintenance of the overall structure of the airport pavement.

[0070] The control method of the flatness accuracy of the pavement soil foundation and the top surface of the base is as follows:

[0071] Step A1, control the flatness accuracy of the compacted soil foundation and the base layer of the pavement structural layer from bottom ...

Embodiment 3

[0075] The new prefabricated airport pavement system and method, through the precision control method of the road surface soil foundation and the top surface of the base, the production method of the prefabricated pavement panel prefabrication factory, the on-site assembly method of the prefabricated pavement pavement, and the rapid and automatic leveling of the prefabricated pavement pavement The method, the seaming method of the prefabricated pavement, the grouting and void detection method of the prefabricated pavement, and the rapid replacement method of the prefabricated pavement realize the accurate and rapid installation, replacement and maintenance of the overall structure of the airport pavement.

[0076] The production method of the fabricated road panel prefabrication plant is as follows:

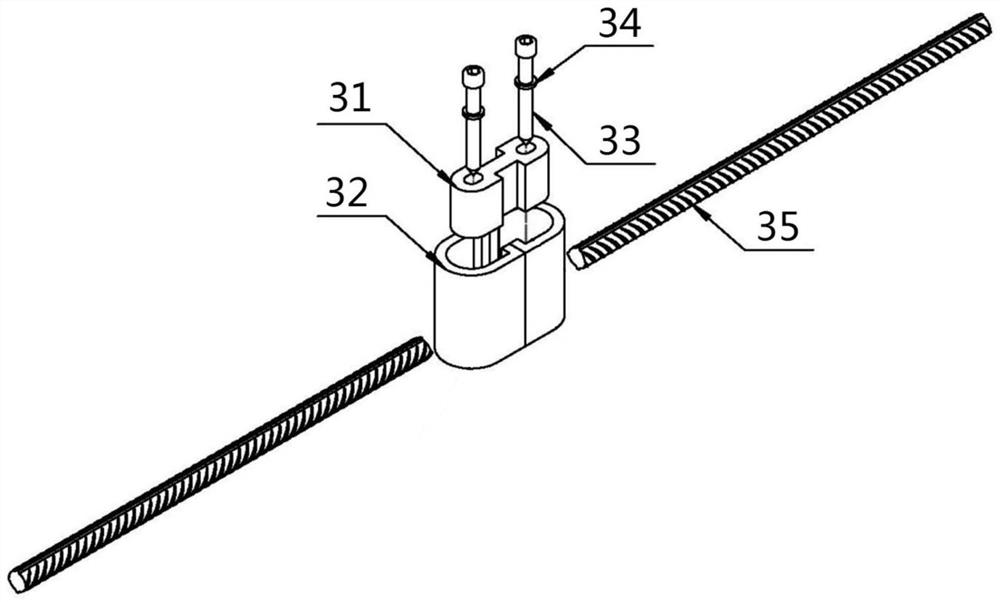

[0077] Step B1, clean up the steel mold, and accurately install all the embedded parts in the road panel according to the position and spacing of the construction drawing, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com