Depth-adjustable immersed hydraulic reclamation pipe orifice and hydraulic reclamation method thereof

An adjustable, submerged technology, applied in construction, infrastructure engineering and other directions, can solve the problems of inaccurate sediment accumulation position, easy diffusion of dredged soil, poor ability to resist wind and waves, etc., achieve accurate sediment filling and reduce pollution , the effect of strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

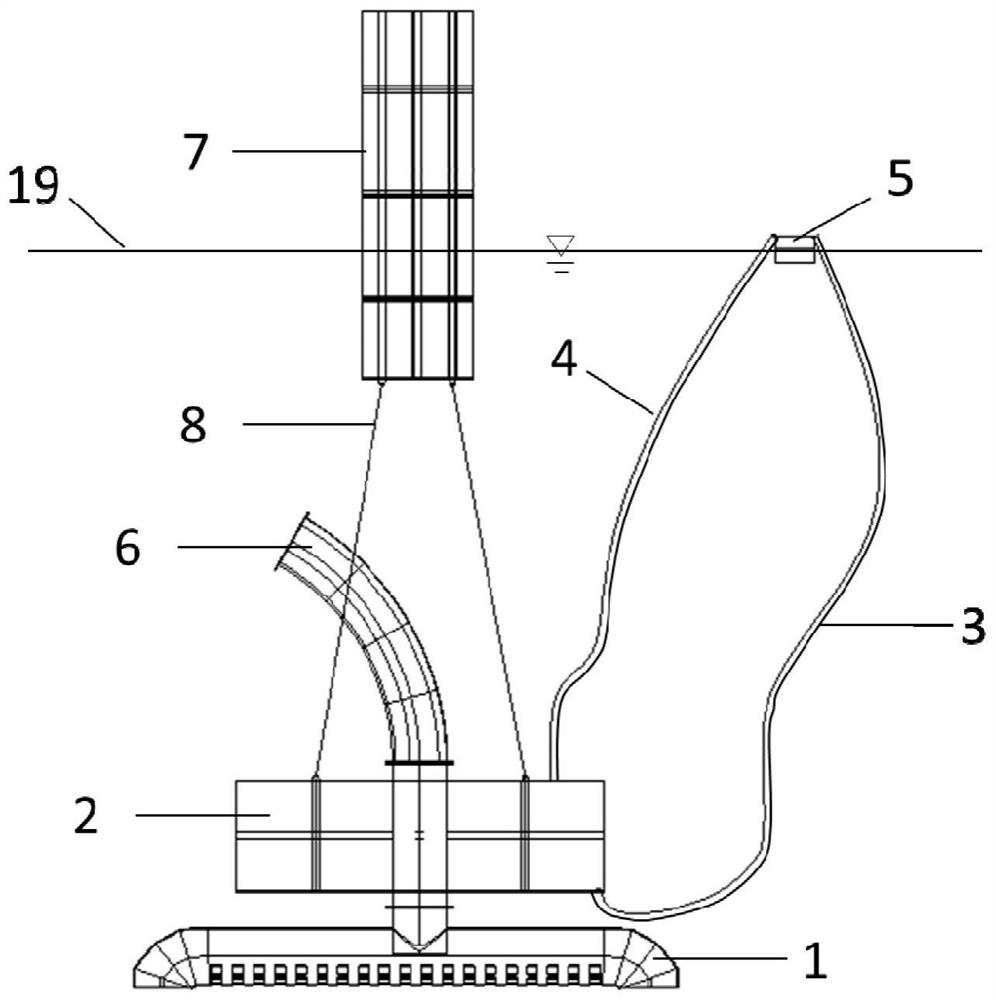

[0034] see Figure 1 to Figure 6 , this embodiment provides a depth-adjustable submerged blow-fill nozzle, including an underwater diffuser 1, an underwater buoy box 2, a long rubber hose 6, a water buoy 7, a water pipe 3, an air pipe 4, and a small buoy 5 and wire rope 8.

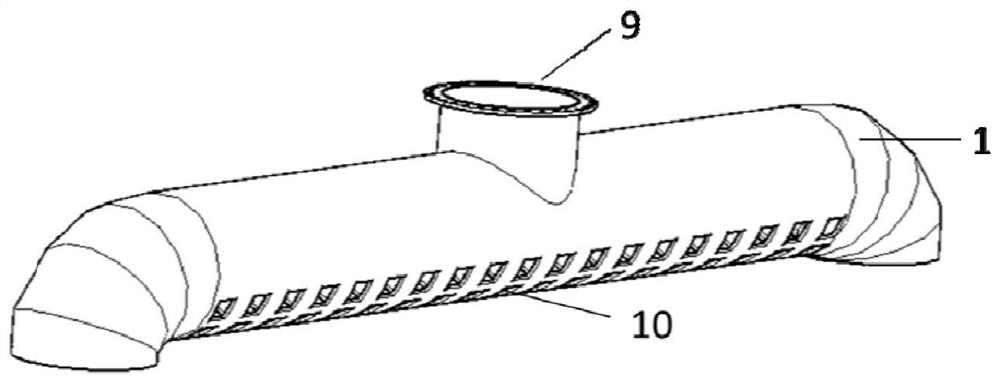

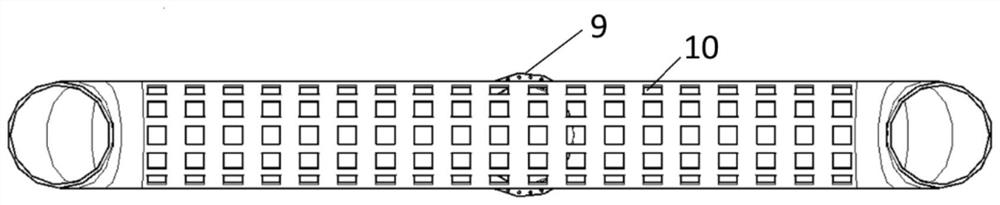

[0035] The underwater diffuser 1 is welded by a horizontal pipe, elbow pipes at both ends of the horizontal pipe and a connecting pipe on the upper part of the horizontal pipe. The bottom of the horizontal pipe is provided with several diffusion holes 10, and the top of the connecting pipe is provided with a flange 9.

[0036] The main surface of the underwater floating tank 2 is welded by steel plates, and the whole is a cubic structure. The middle part of the underwater floating tank 2 has a hole, and a steel pipe is welded at the opening. The upper and lower ends of the steel pipe extend out of the underwater floating tank 2. , the upper and lower ends of the steel pipe are provided with flanges 9; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com