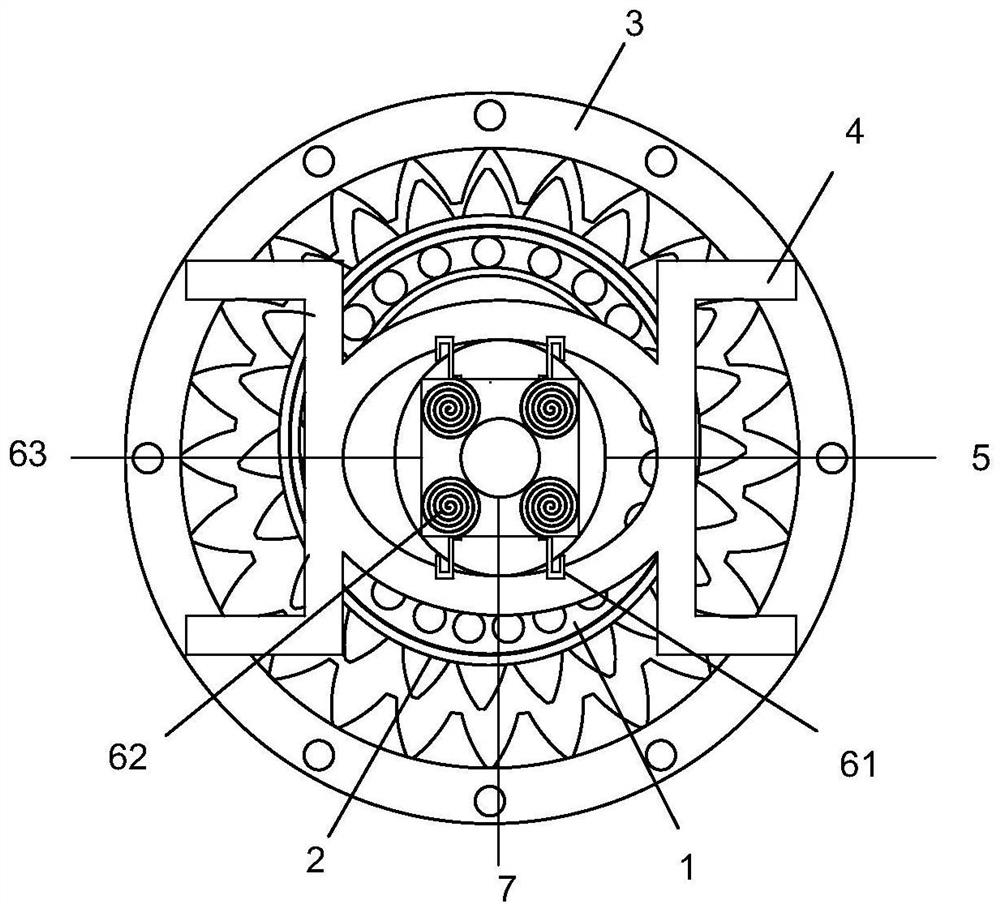

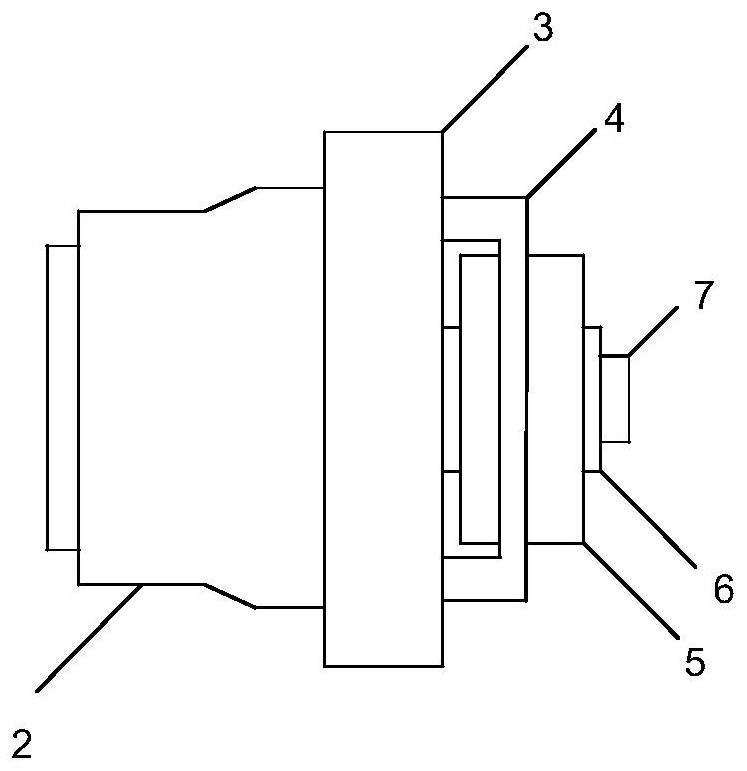

Harmonic gear reducer

A gear reducer and harmonic technology, which is applied in the field of harmonic gear reducer, can solve the problems of reduced service life, increased cost, and difficulty in heat dissipation of harmonic gear reducers, so as to reduce frictional resistance, increase service life, and increase sequential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

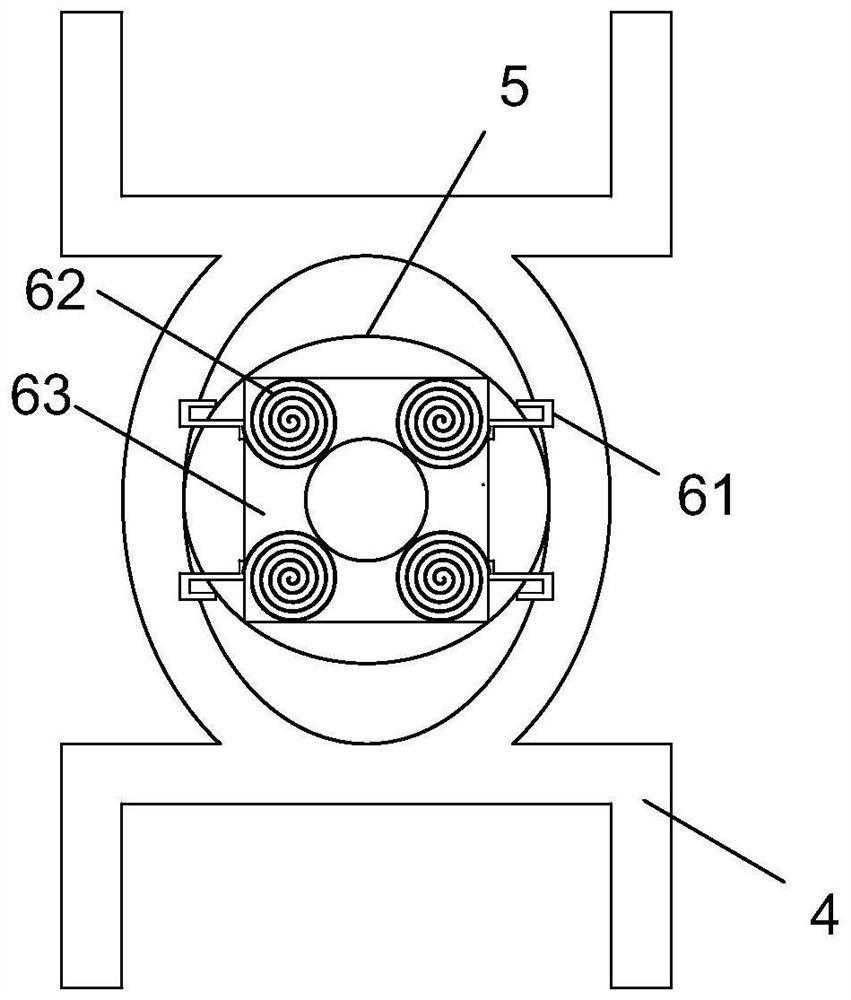

[0026] As an embodiment of the present invention, an air hole 51 is provided at b in the annular air chamber 5, the wall thickness at a in the annular air chamber 5 is set to 10-20 cm, and b in the annular air chamber 5 The wall thickness is set to 3-5cm.

[0027] Because a place in the annular air chamber 5 is the contact part of the fixing mechanism 4 and the annular air chamber 5, so the wall thickness at a in the annular air chamber 5 is set to 10-20cm, which can increase the wear resistance of the annular air chamber 5, thereby increasing the annular air chamber. For the service life of the air chamber 5, the wall thickness at b in the annular air chamber 5 is set to 3-5 cm. When the gas is ejected from the air hole 51 at b, vibration will occur at b in the annular air chamber 5, thereby driving the air hole 51 to vibrate. The movement direction of the ejected gas is disordered, thereby increasing the heat dissipation area, thereby increasing the service life of the harmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com