Industrial VOC emission monitoring sensor and mounting structure thereof

A technology for monitoring sensors and installation structures, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of troublesome power connection, increased power consumption and use costs, and increased costs, so as to facilitate installation and use, reduce use and installation, Realize the effect of electric energy conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

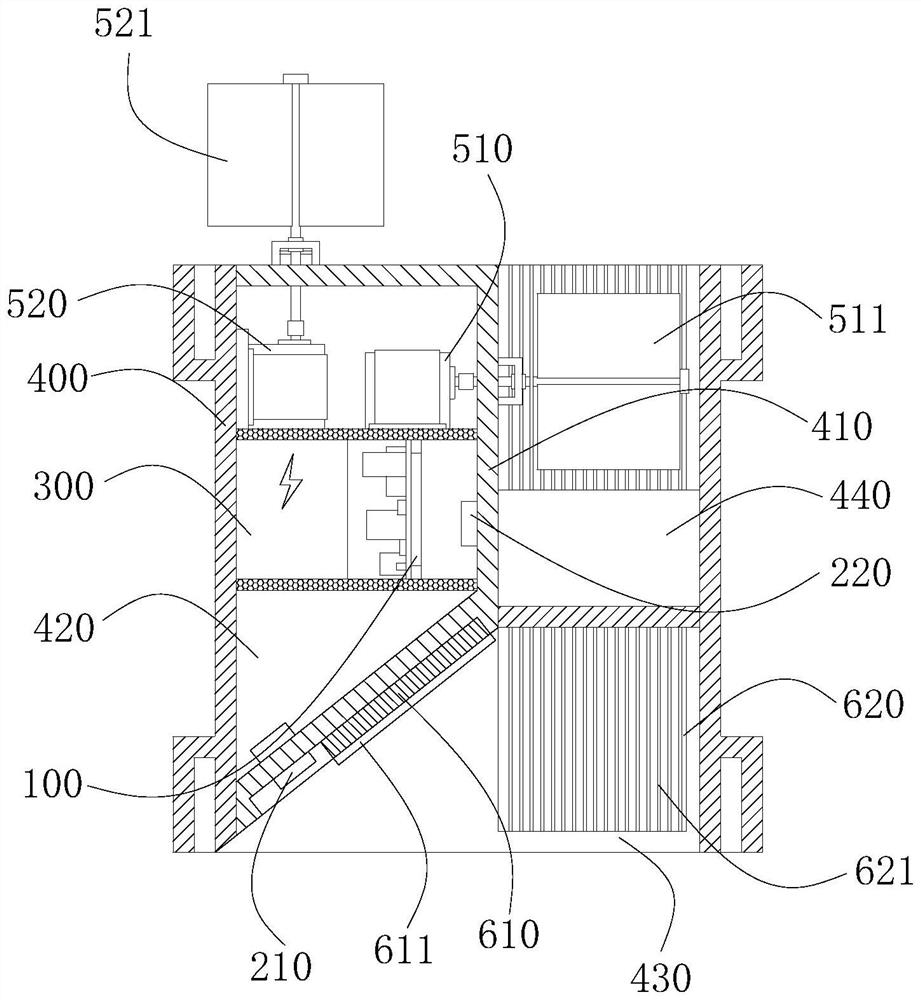

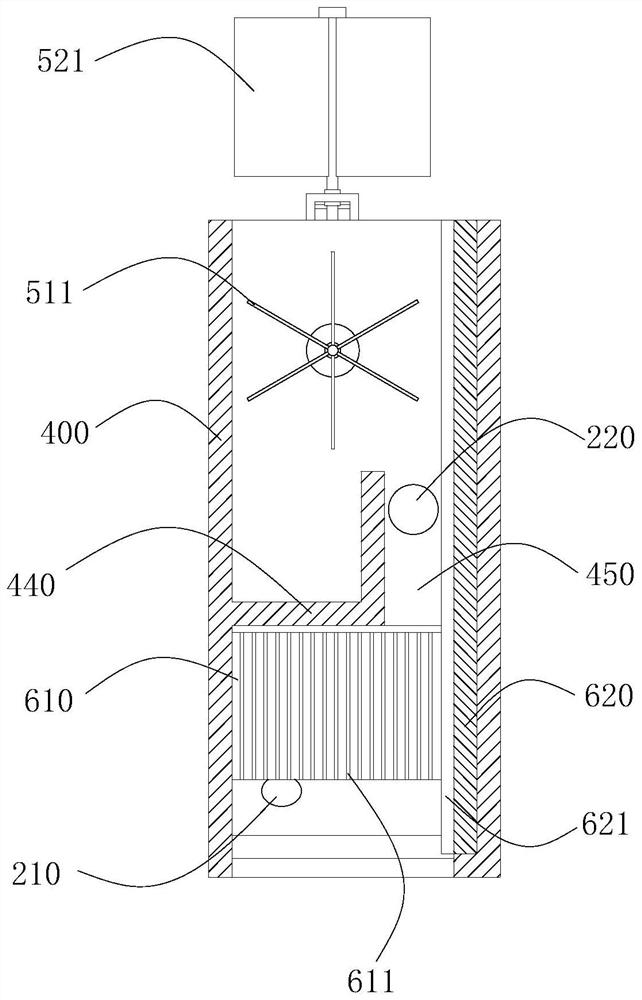

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

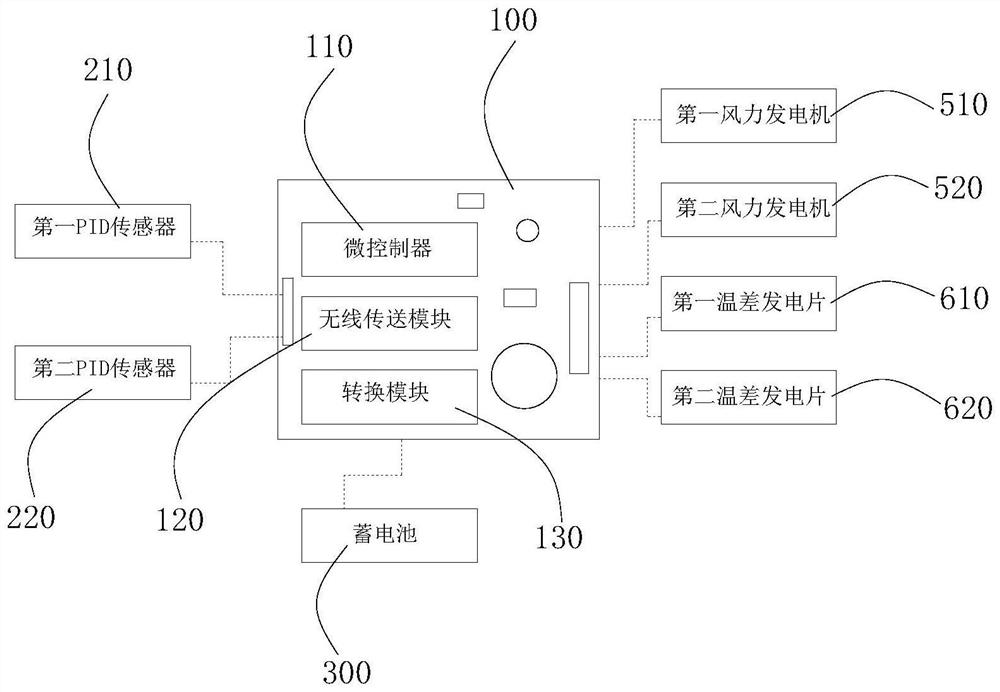

[0026] like figure 1 As shown, an industrial VOC emission monitoring sensor is disclosed in a specific embodiment of the present invention, including a circuit board 100, a microcontroller 110 and a wireless transmission module 120 integrated on the circuit board 100, and the microcontroller 110 is electrically connected. The connected first PID sensor 210 and the second PID sensor 220; the first PID sensor 210 and the second PID sensor 220 extend outward through external wires; further, the circuit board 100 is integrated with a conversion module 130 for electric energy conversion, The circuit board 100 is externally connected with a storage battery 300 , a wind power generator set, and a thermoelectric generation sheet group through wires; the electric energy generated by the wind turbine generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com