Underground slurry paving device with turning screw blade combination

A technology of spiral blades and padding, applied in the direction of soil lifting machinery, shovels, plows, etc., can solve problems such as low efficiency, time-consuming and labor-intensive, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

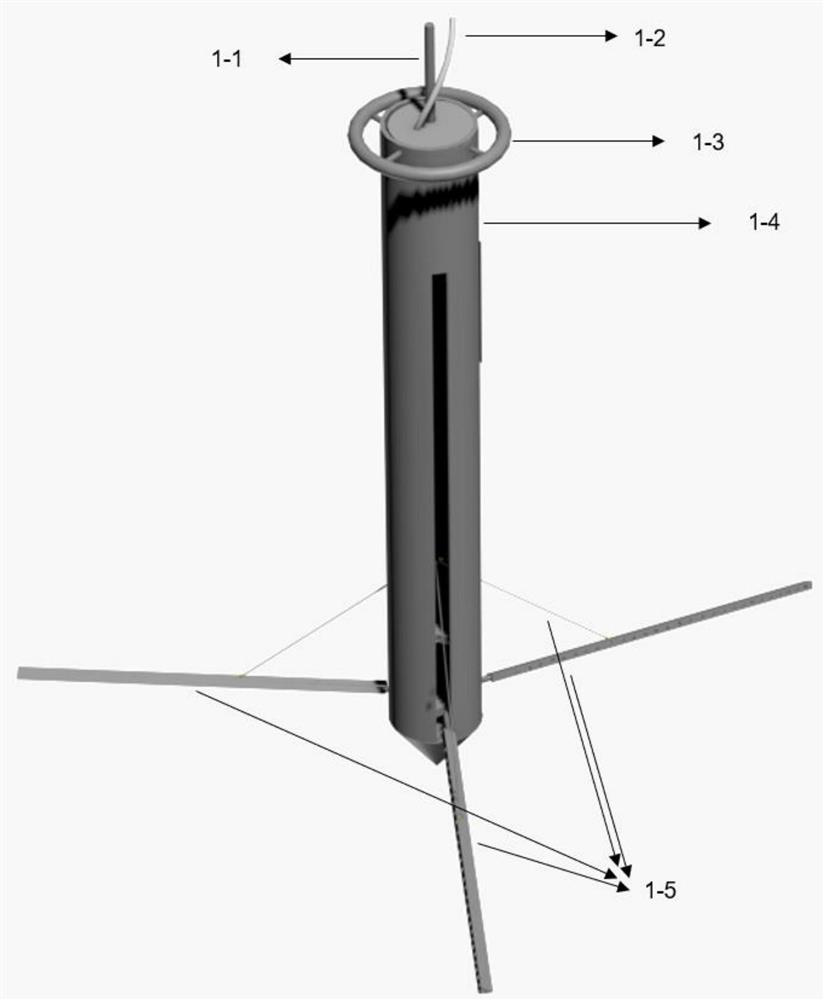

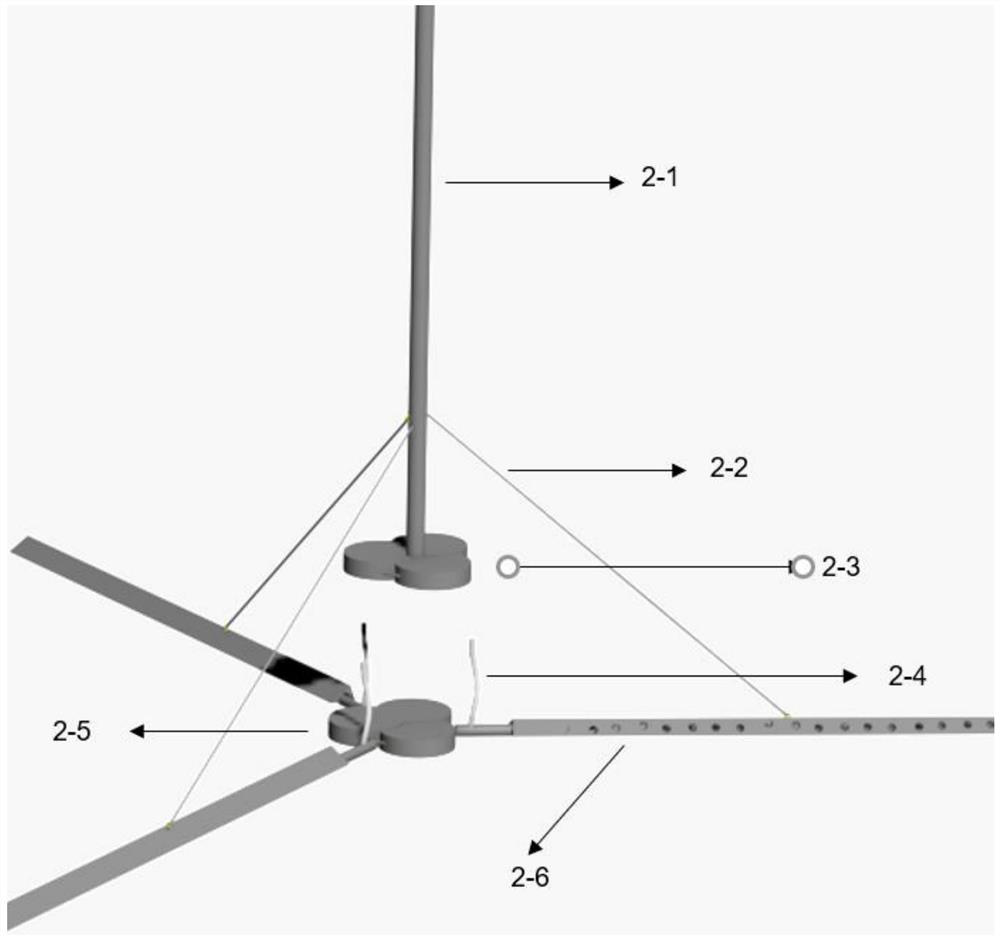

[0016] figure 1 It is a schematic diagram of the overall structure, which is composed of a hollow drill rod and an arc handle on it, a grouting conduit, a movable disc control rod and a reversible helical blade connected to it. The steps to use are:

[0017] 1. Insert 1-4 hollow drill pipes into the ground as needed.

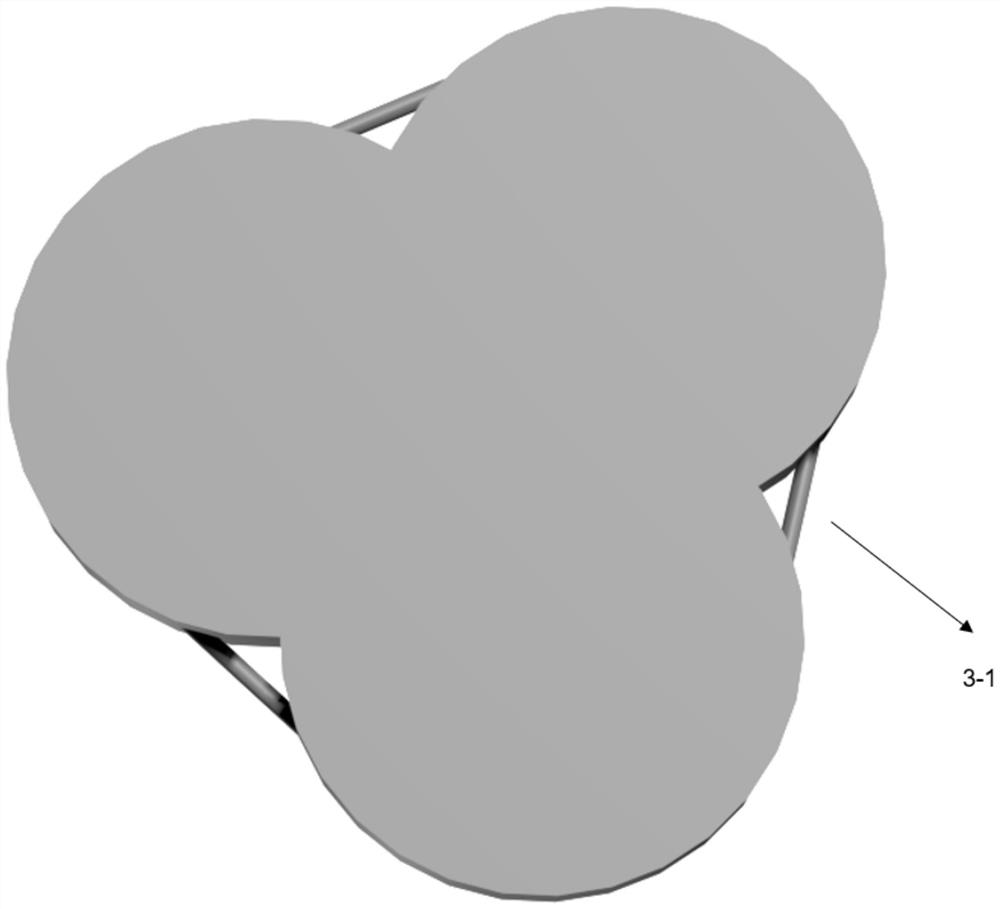

[0018] 2. Press the 1-1 (2-1) movable disc control lever to make the 1-5 reversible helical blade combination open underground.

[0019] 3. Turn on the high-pressure pouring machine, so that the slurry material flows into the 2-6 wedge-shaped blade through the 1-2 (2-4) grouting conduit, and then leaks out from the 4-1 circular continuous small hole.

[0020] 4. Twist the 1-3 arc handle of the 1-4 hollow drill pipe at a uniform speed, so that the 1-5 reversible helical blade combination is driven by the 2-2 bearing rod to follow the 1-4 hollow drill pipe to rotate in the ground, and the slurry The body materials are laid parallel and evenly on the ground.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com