Drivable spiral progressive low-injury integrated bone puncture needle

A low-injury, one-piece technology, used in puncture needles, trocars, internal bone synthesis, etc., can solve the problems of pedicle and vertebral body injury, reduced puncture success rate, increased surgical risk, etc. The effect of destroying, reducing surgical complications, and simplifying surgical procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

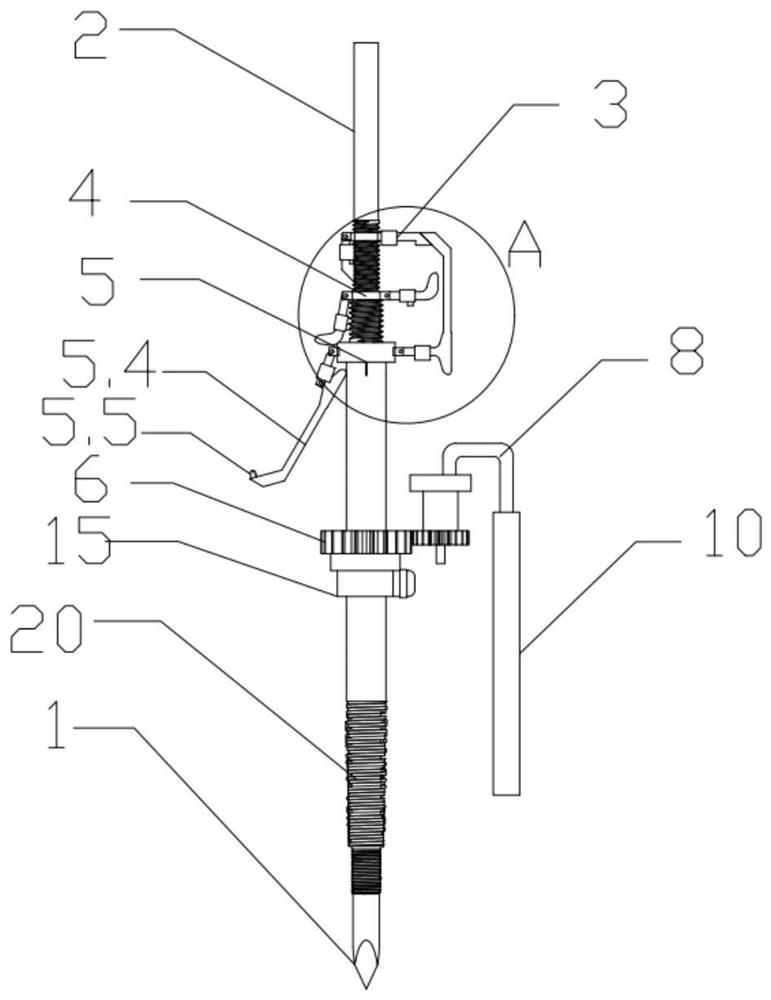

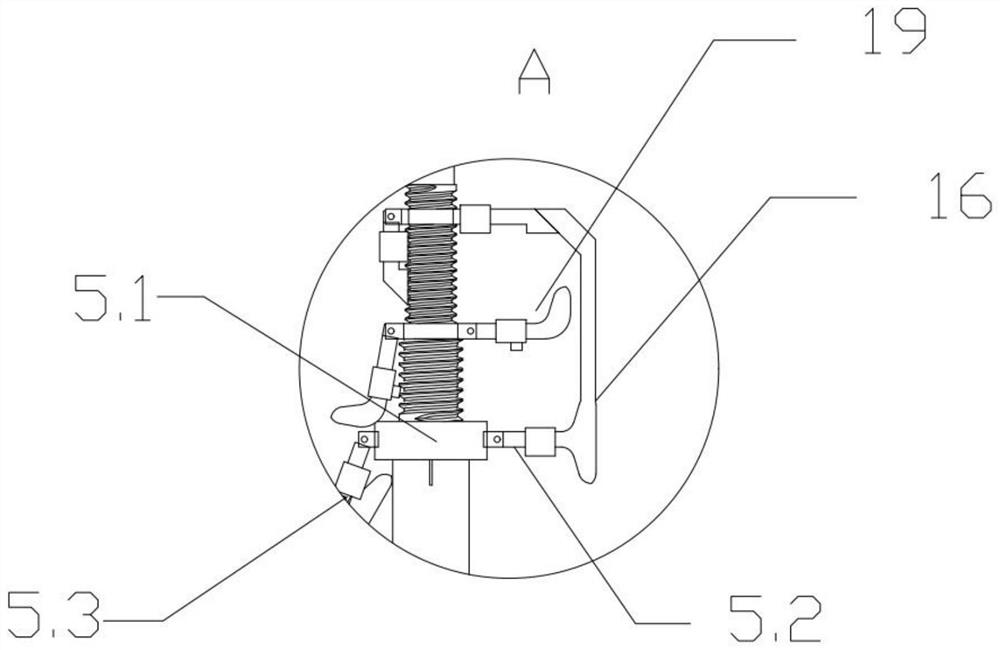

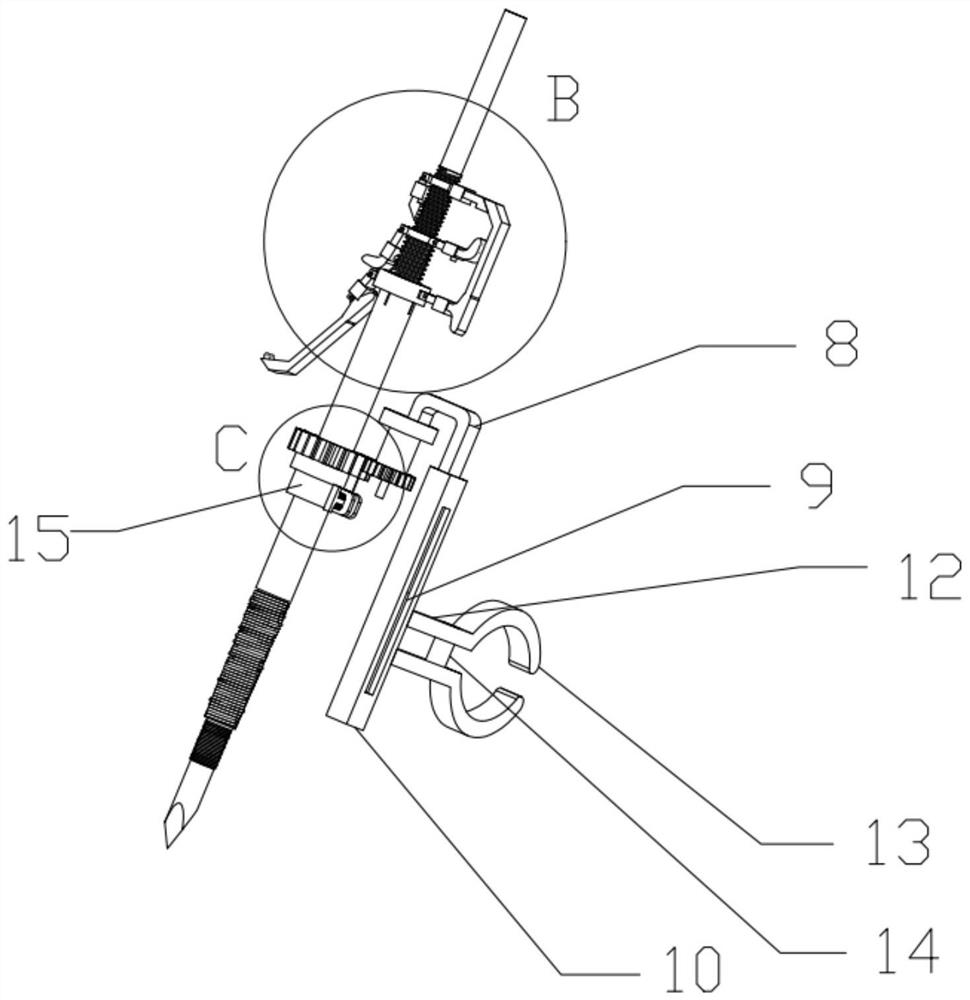

[0029] Attached below Figure 1-8 The present invention is described in further detail.

[0030] A drivable spiral progressive low-injury integrated bone puncture needle, comprising:

[0031] A bone spur needle body, one end of the body is provided with a tapered tip 1, and the other end of the body is provided with a threaded assembly section 2;

[0032] The assembly section 2 is sequentially screwed with an outer rod handle 3, a middle rod handle 4 and an inner rod handle 5, and the inner rod handle 5 is set to be openable;

[0033] A connection mechanism is provided on the main body and between the tip part 1 and the inner rod handle 5. The connection mechanism includes a detachable gear 6, a fixed locking part for limiting the gear 6 and an adjustable clip connected to the gear 6. Connecting part, the clamping part is used for clamping the hospital bed.

[0034] In the process of specific implementation, open the outer rod handle 3, and the fully opened state can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com