Steam condensation method

A technology of steam condensation and steam, which is applied in the direction of steam condensation, separation methods, chemical instruments and methods, etc. It can solve the problems of large water discharge of cooling towers, idling of water pumps, and affecting heat exchange efficiency, etc., to achieve fast heat exchange efficiency, Effect of reducing intermediate conversion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

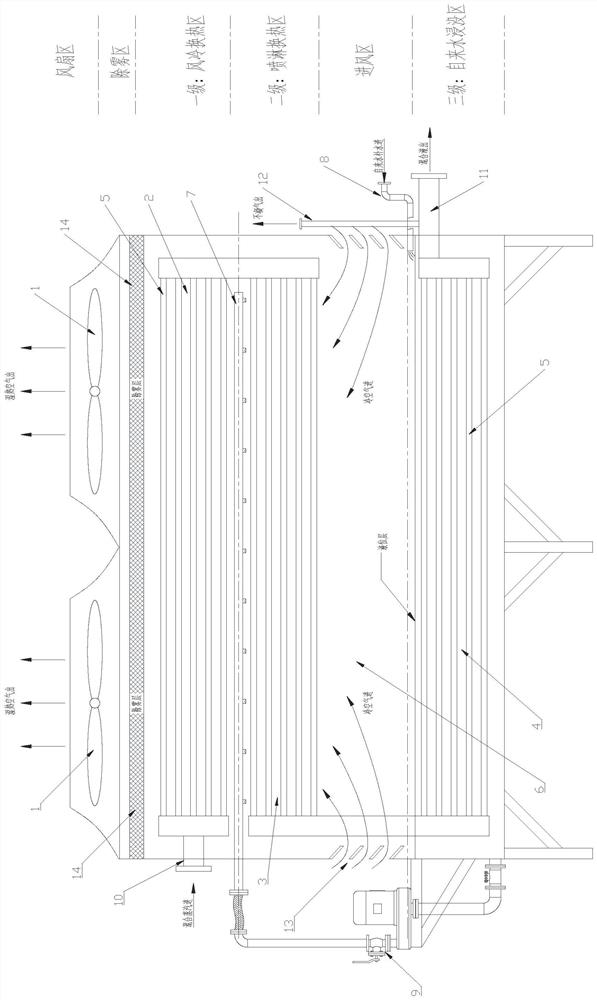

[0027] refer to Figure 1-2 , the steam condensation and heat dissipation integrated equipment in this embodiment includes a fan 1, a primary heat exchange area (device) 2, a secondary heat exchange area (device) 3, an air inlet area 6, and a third stage heat exchange area (device) ) 4. The defogging layer 14 arranged between the fan 1 and the first-stage heat exchange area 2, the water inlet pipe 8 set corresponding to the third-stage heat exchange area 4, and the air inlet 13 arranged corresponding to the air inlet area 6 are used for the second The spray pipeline 7 for spraying and cooling in the first-stage heat exchange area 3, the water pump 9 connecting the third-stage heat exchange area 4 and the spray pipe 7, and the air intake pipe 10 arranged at one end of the heat exchange pipe 5 in the first-stage heat exchange area 2 , a liquid outlet pipe 11 arranged at one end of the heat exchange tube 5 in the three-stage heat exchange area 4 , and a non-condensable gas discha...

Embodiment 2

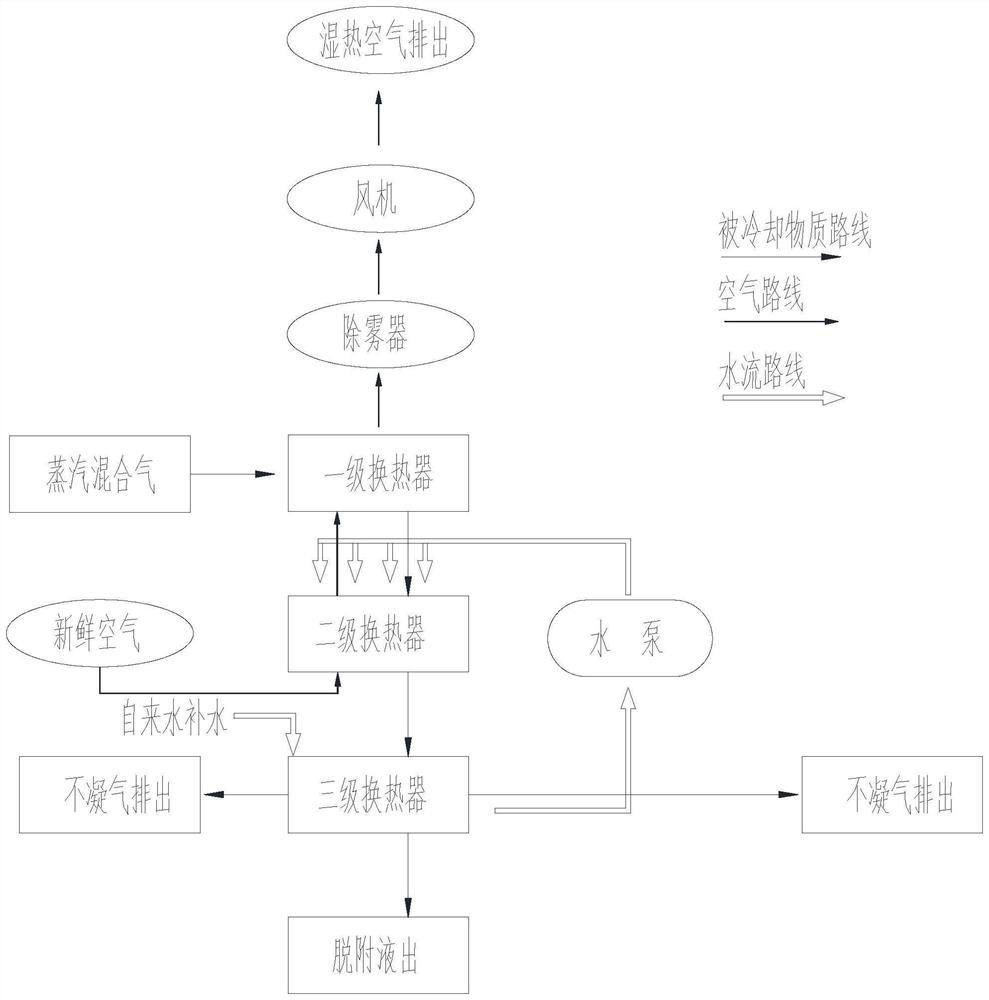

[0037] This embodiment provides a method for cooling and condensing steam based on the steam condensation and heat dissipation integrated equipment in Embodiment 1. The steam enters from one end of the heat exchange tube 5 in the primary heat exchange zone 2, and passes through the primary stage in turn. The heat exchange zone 2 is cooled once, the secondary heat exchange zone 3 is cooled twice, and the third heat exchange zone 4 is cooled three times. It is used to spray and lower the temperature of the material in the heat exchange tube 5 in the secondary heat exchange area 3; The contents are cooled.

[0038] Wherein, when the temperature is lowered once, the air flows from bottom to top to cool the material in the heat exchange tube 5, and the temperature of the material in the heat exchange tube 5 is lowered by using air as a medium; Up-down flow cools the material in the heat exchange tube 5, and uses liquid and air as the medium to reduce the temperature of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com