Anti-aging leather finishing agent processing device

A leather finishing agent and processing device technology, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as temperature instability and the influence of raw material ratios of coating agents, and achieve the goal of avoiding raw material ratios affect, guarantee quality and quality, guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

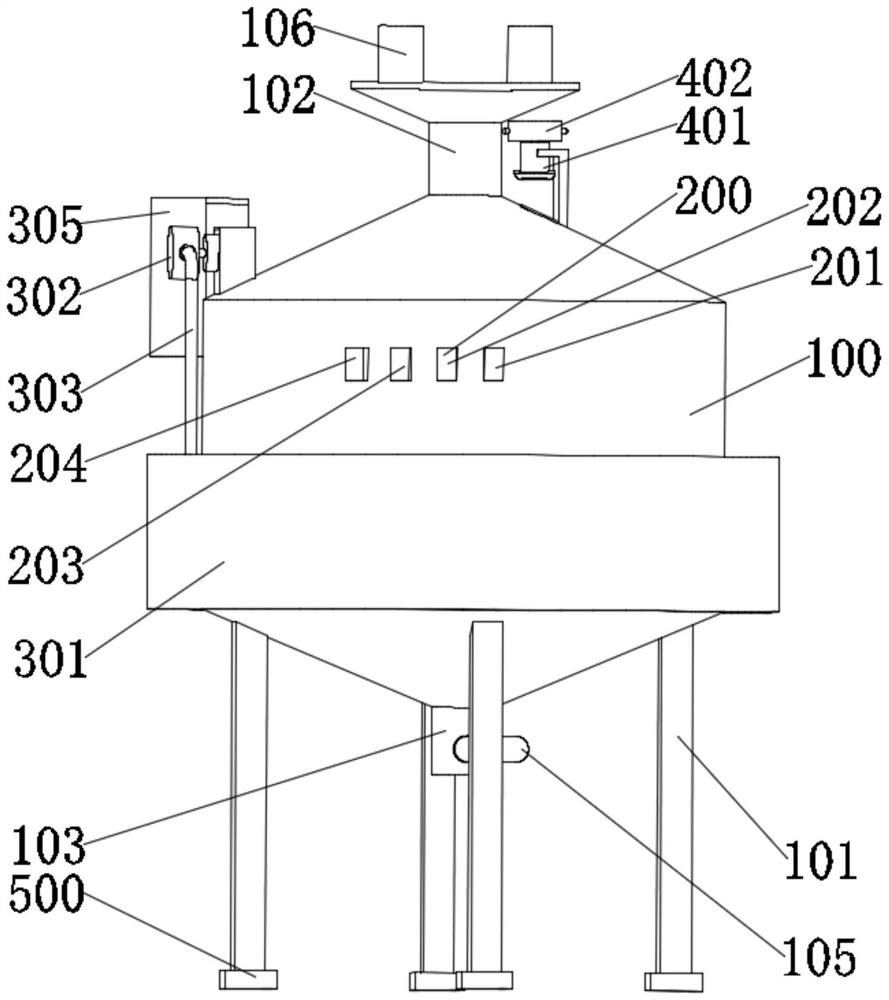

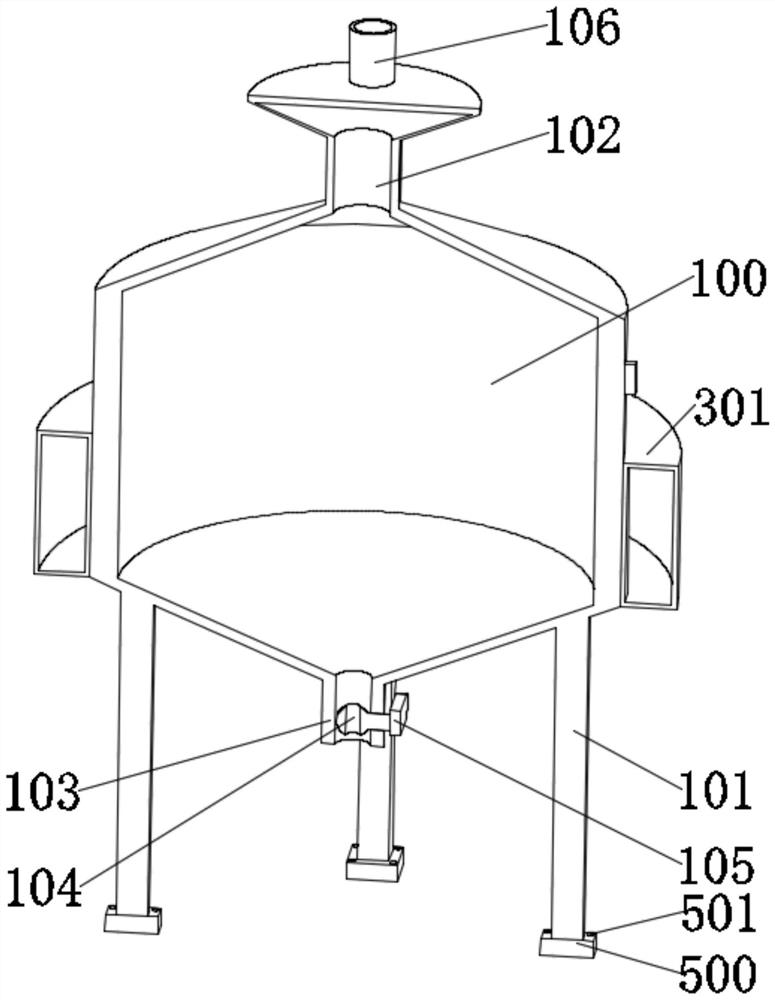

[0032] refer to Figure 1-4 As shown, an aging-resistant leather finishing agent processing device includes a reaction kettle 100, a supporting foot 101, a raw material inlet 102 and a discharge opening 103, and four sets of supporting feet are symmetrically fixed and fixed on the lower surface of the reaction kettle 100 near the edge 101, the upper surface of the reaction kettle 100 is fixedly installed with a raw material inlet 102 near the center, and the raw material inlet 102 communicates with the inside of the reactor 100, and the lower surface of the reactor 100 is fixed with a discharge outlet near the center. port 103, and the discharge port 103 communicates with the inside of the reactor 100, the inner wall of the discharge port 103 is fixedly installed with a ball valve 104, the end of the ball valve 104 is fixedly mounted with a handle 105, and the upper surface of the raw material inlet 102 is symmetrically fixed with two The raw material channel 106 and the raw m...

Embodiment 2

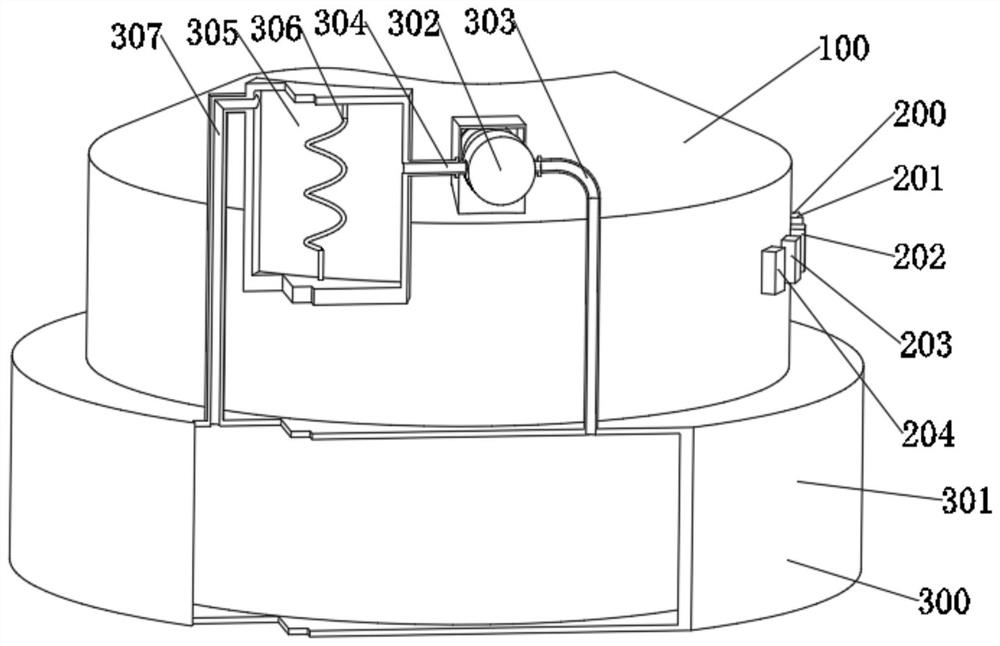

[0035] to combine figure 1 , figure 2 with image 3As shown, based on the above-mentioned embodiment 1, the control assembly 200 includes a temperature detector 201, a signal processor 202, a signal transmitter 203 and a control switch 204, and the outer surface of the reactor 100 is fixedly equipped with a temperature detector 201, and the A signal processor 202 is fixedly installed on the outer surface, a signal transmitter 203 is fixedly installed on the outer surface of the reactor 100, a control switch 204 is fixedly installed on the outer surface of the reactor 100, and the temperature detector 201, the signal processor 202 and the signal transmission The electrical connection between the devices 203, and the signal connection between the signal transmitter 203 and the control switch 204.

[0036] Based on the above structure, the temperature is detected by the temperature detector 201 , the signal is processed by the signal processor 202 , the signal is transmitted b...

Embodiment 3

[0038] to combine figure 1 , figure 2 with image 3 As shown, based on the above-mentioned embodiment 1 or 2, the heating assembly 300 includes a medium box 301, a water pump 302, a flow guide pipe 303 and a connecting pipe 304. The water pump 302 is fixedly installed by the fixed block, and the upper surface of the medium box 301 is fixedly equipped with a guide tube 303, and the inside of the guide tube 303 communicates with the medium box 301, and the guide tube 303 is fixedly connected with the water pump 302, and the water pump 302 The other end is fixedly connected with a connecting pipe 304, and the connecting pipe 304 communicates with the flow guide pipe 303 through the water pump 302, and a heating box 305 is fixedly installed on the outer surface of the reaction kettle 100 corresponding to the connecting pipe 304, and the connecting pipe 304 and the heating The inside of the box 305 is connected, and the heating wire 306 is fixedly connected between the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com