Production device and method of feed and feed additive

A feed additive and production device technology, which is applied in feed, chemical instruments and methods, transportation and packaging, etc., can solve the problems affecting the quality and production and processing efficiency of new feed and feed additives, and the difficulty in controlling and matching the ratio of feed and feed additives. Problems such as poor mixing effect, to achieve the effect of convenient and fast control, accurate feeding, and simplified device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

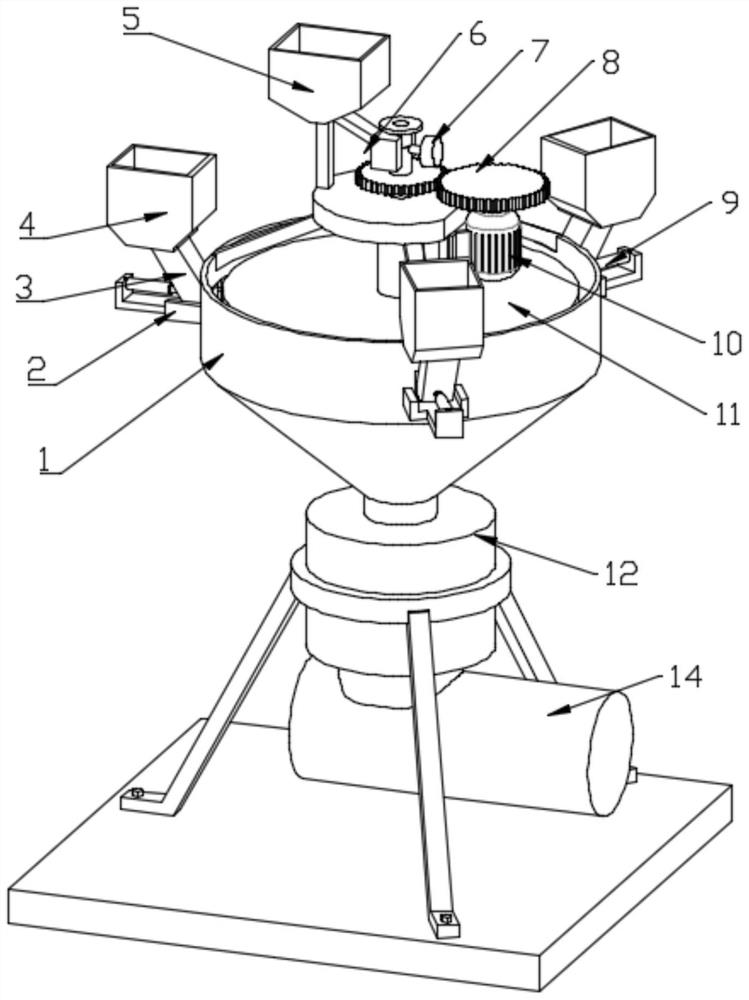

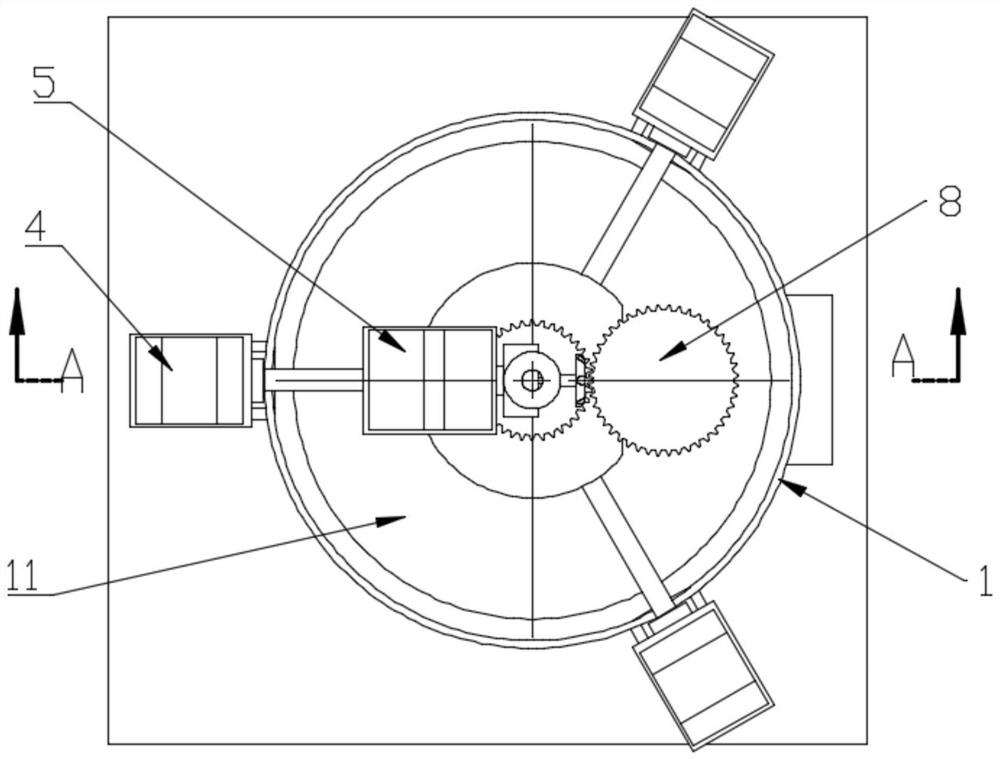

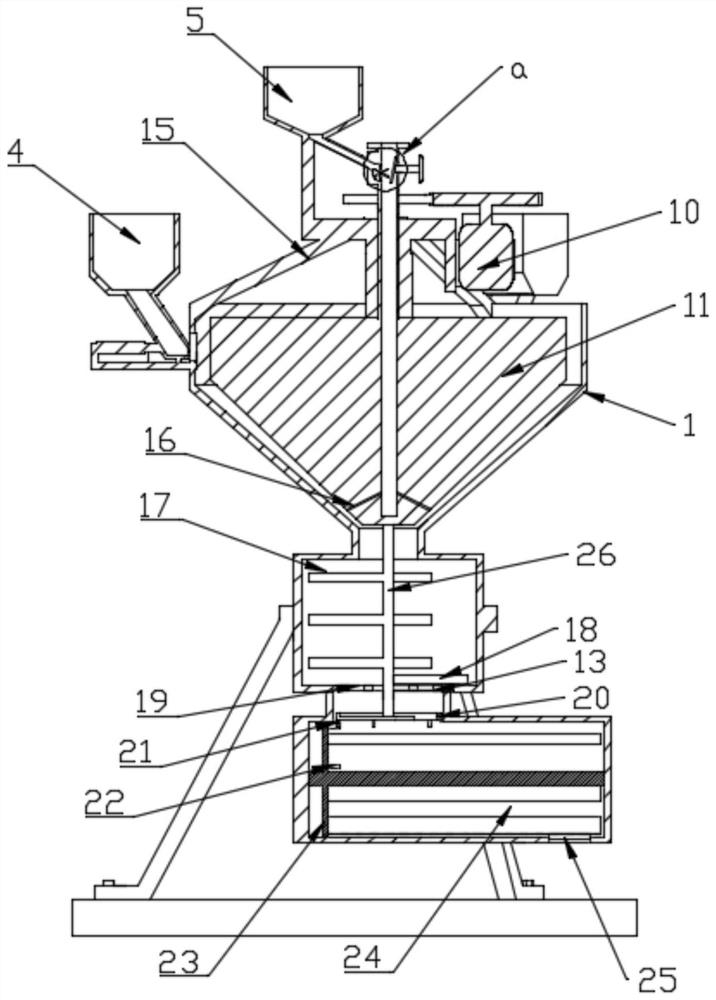

[0051] refer to Figure 1 ~ Figure 3 In this embodiment, a production device for feed and feed additives is proposed, which is used to grind and mix feed raw materials and additives and form granules. The production device for feed and feed additives includes: a grinding bucket 1, a mixing box 12 and drying box 14.

[0052]The grinding bucket 1 is a funnel-shaped structure, that is, an upper cylinder and a lower conical connected structure. The grinding bucket 1 can be made of stainless steel, so as to ensure a certain rigidity and avoid deformation of the grinding bucket 1 during operation.

[0053] The mounting frame 15 is fixedly connected to the grinding bucket 1 for support and installation. The mounting frame 15 includes a number of mounting rods and mounting tables, the outer ends of the mounting rods are fixedly connected to the top of the grinding bucket 1, and the mounting table is fixedly connected to the mounting rod inner end.

[0054] The grinding pestle 11 is ...

Embodiment 2

[0070] refer to Image 6 , a kind of production method of feed and feed additive is proposed in the present embodiment, comprises the steps:

[0071] S1. The camera takes pictures of the raw materials inside the feed hopper 4 .

[0072] S2. Analyzing the picture of the raw material to obtain the particle size characteristics of the raw material.

[0073] S3. Find a preset feature-gap information table to obtain the feed gap.

[0074] S4. Pushing the driving member 9 to drive the material guiding channel 3 to slide, so that the gap between the material guiding channel 3 and the grinding pestle 11 corresponds to the feeding gap.

[0075] S5. The material inside the feed hopper 4 enters into the inside of the grinding hopper 1 for grinding by gravity.

[0076] S6. Find a preset material, additive-flow rate comparison table to obtain the water flow rate.

[0077] S7. The adjusting part 7 adjusts the flow rate of the water pipe to correspond to the flow rate of the water flow. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com