Machine tool rotary table protection device and numerical control gear hobbing machine

A protection device and turntable technology, which is applied in the direction of gear cutting machine, gear tooth manufacturing device, gear teeth, etc., can solve the problems of eccentricity, chip removal, protective installation, etc., and achieve the effect of improving the fault tolerance rate and solving the problem of eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

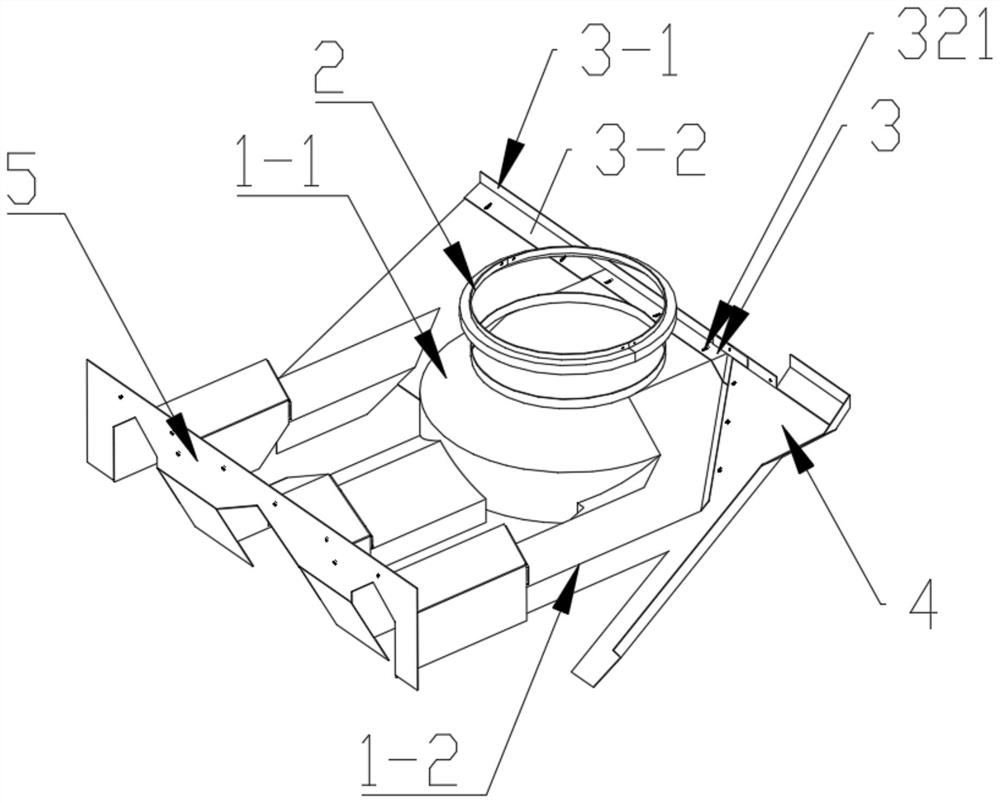

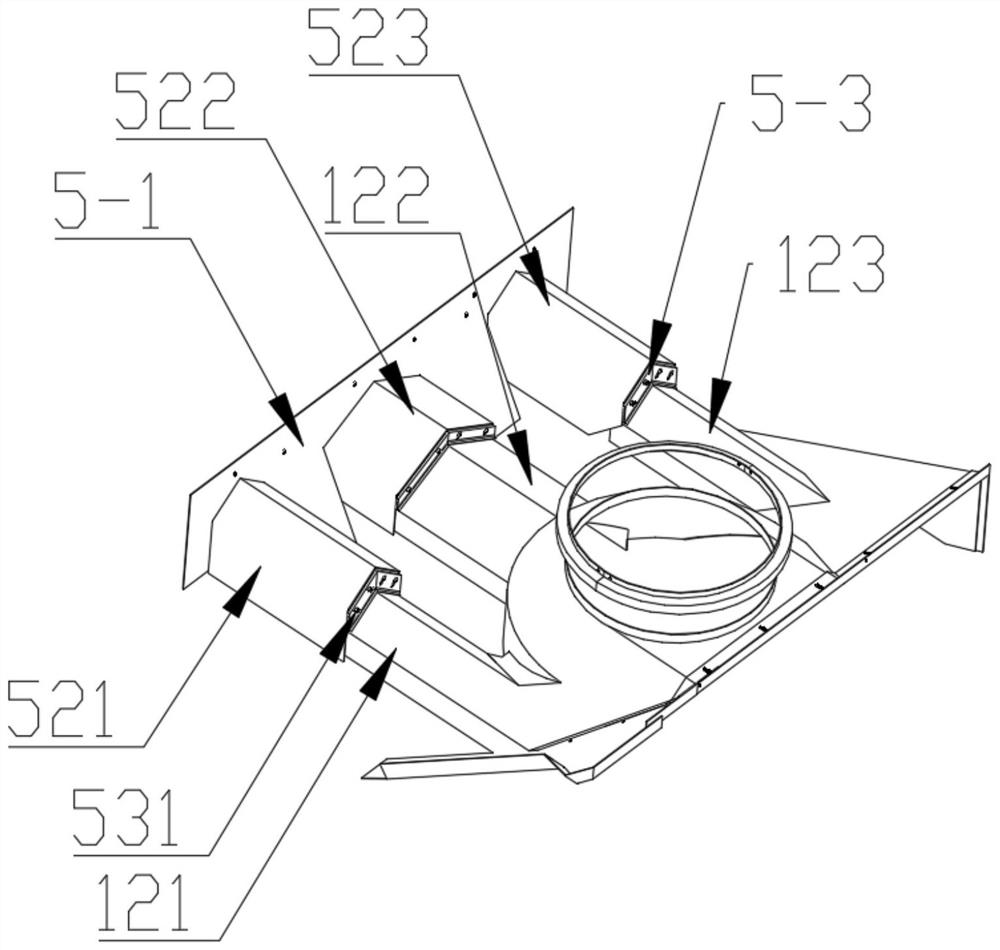

[0035] Such as Figure 1-2 As shown, a machine tool turntable protection device includes a turntable protective cover 1, a turntable support 2, a small column connecting plate 3 and a large column scraping plate structure 5, and the turntable protective cover 1 is provided with a circular arc for installing the turntable 10 The turntable bracket 2 on the surface, one end of the turntable protective cover 1 is fixedly connected with the small column connecting plate 3 and the other end is movably connected with the large column scraping plate structure 5, and the large column scraping plate structure 5 is used for scraping Turntable protective cover 1 is covered with iron filings.

[0036] On this basis, one side of the turntable protective cover 1 is also provided with a chip removal plate 4, one side of the chip removal plate 4 is connected to one side of the turntable protective cover 1 and the other side of the chip removal plate 4 is connected to the small The column conn...

Embodiment 2

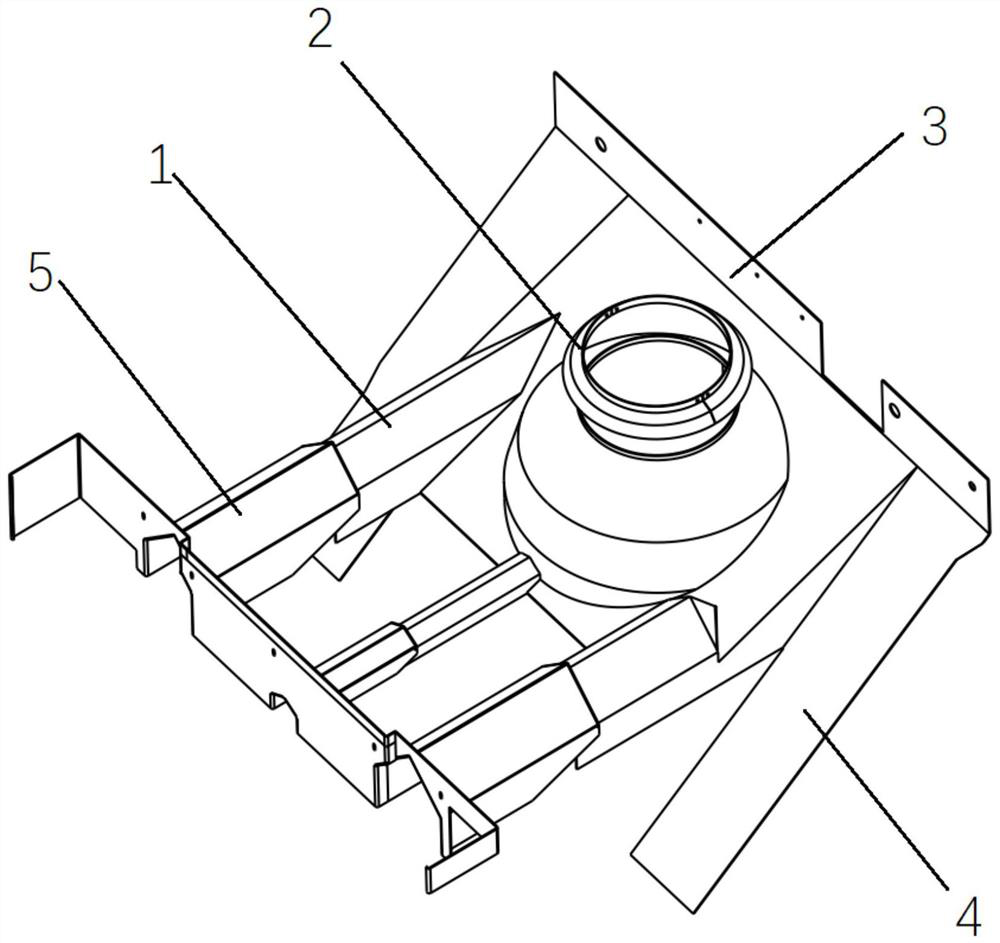

[0057] On the basis of Example 1, such as image 3 As shown, the turntable bracket 2 is in the shape of a top hat with the center of the turntable 10 as the center, the arc surface on which the turntable 10 can be installed as the inner circle radius, and the distance greater than the turntable 10 radius and not interfering with other components as the radius. The structure is installed on the arc surface of the turntable 10 by screws.

[0058] The purpose of this structure is to prevent iron filings from entering the interior of the turntable 10 from the gap existing at the connection between the arc surface of the turntable protective cover 1 and the turntable 10 .

Embodiment 3

[0060] On the basis of Embodiment 1 or 2, the protective device for the turntable of the machine tool is made of metal sheet metal materials, not limited to stainless steel and stainless iron materials.

[0061] The diameter of the circle in the turntable protective cover 1 is relatively large, so the problem of eccentricity will not occur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com