Stacking system of railway vehicle

A rail vehicle and stacking technology, which is applied in the field of stacking systems, can solve the problems of low logistics turnover speed and efficiency, and achieve the effect of improving logistics turnover speed and efficiency and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

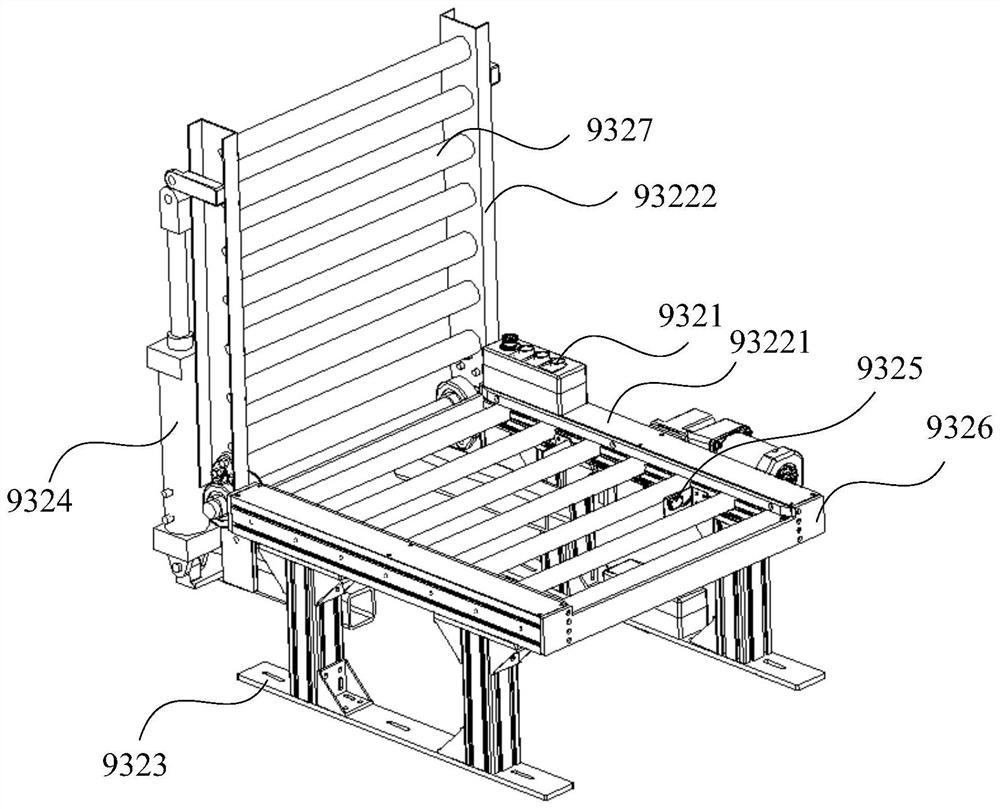

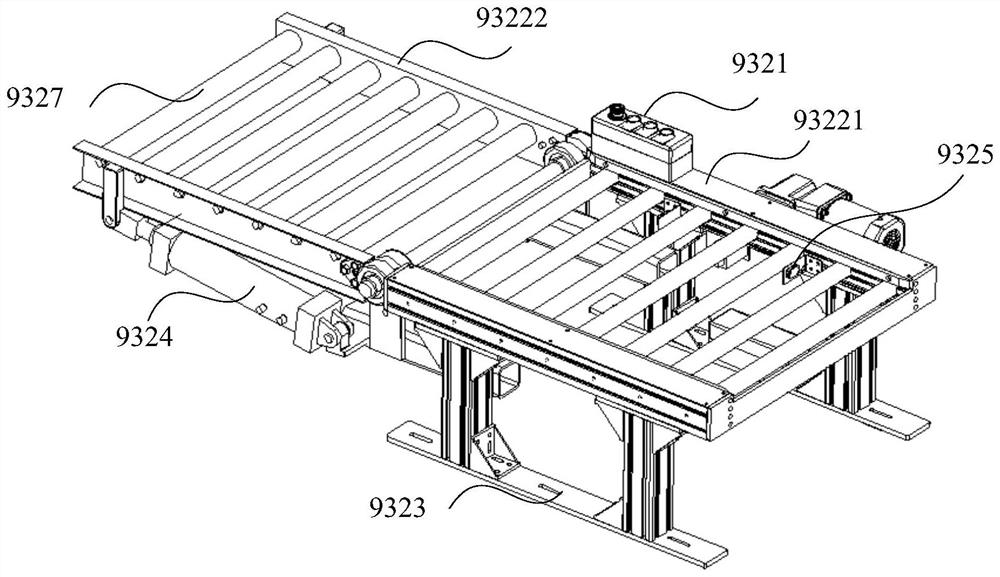

[0118] see Figure 5-7 , Figure 5 A schematic diagram of an axonometric structure of a stacking system for a rail vehicle provided in an embodiment of the present application; Image 6 for Figure 5 Schematic diagram of the main view structure; Figure 7 for Figure 5 Schematic diagram of the lateral structure.

[0119] A stacking system 91 provided by the present application includes a stacker frame 911 , a fork 912 , a stacker traveling drive device and a control device 913 . The stacker frame 911 is preferably a rectangular frame, and the edges of the rectangular frame can be detachably connected to facilitate production and processing. The forks 912 are located on the stacker frame 911 and are used to pick and place the ULD. The stacker traveling drive device is also located on the stacker frame 911, and is used to drive the stacker to travel in the rail vehicle. There are preset tracks on the floor of the stacker, such as slide rails, which cooperate with the trav...

Embodiment 2

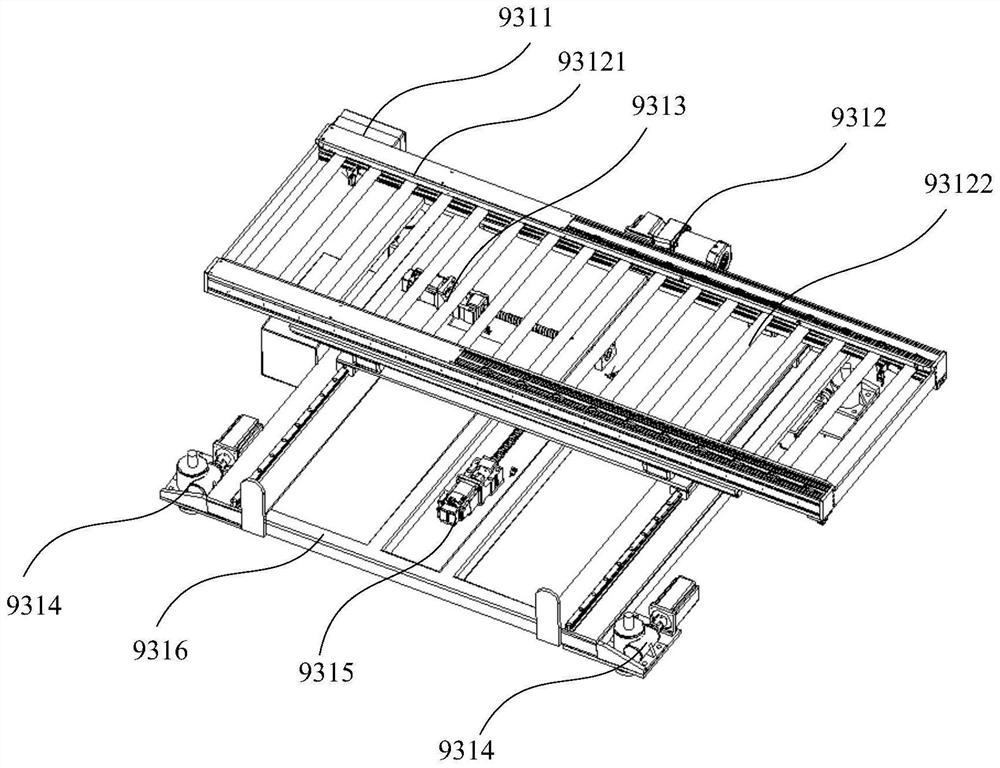

[0148] In one embodiment, the platform conveying system 931 includes a platform conveying device connected to the master control device, and the device includes a platform conveying assembly 9312 and a position adjusting assembly. Among them, the platform conveying assembly 9312 is used for conveying goods, one end of the platform conveying assembly 9312 is located on the platform, and the other end is used for docking with the conveying system 932 at the door; for example, it is configured as a conveyor belt, a conveyor chain or other conveying equipment. The position adjustment assembly is connected with the platform conveying assembly 9312, and the position adjustment assembly is used to drive the platform conveying assembly 9312 to adjust the spatial position; the master control device is respectively connected with the platform conveying assembly 9312 and the position adjustment assembly, and can be connected by wired or wireless communication. The device controls the acti...

Embodiment 3

[0177] like Figure 21 as shown, Figure 21 It is a schematic flowchart of a storage management method for rail vehicles provided in the embodiment of the present application. In a specific embodiment, the storage management method for rail vehicles provided by the application includes:

[0178] S941: Obtain the ULD information of the ULD to be put into storage;

[0179] Among them, ULD information generally includes ULD information including cargo on-station information, cargo arrival information, cargo attribution information and cargo characteristic information. Cargo attribution information such as the identity information of the belonging passenger, seat number and other information; cargo characteristic information such as storage conditions (such as storage temperature, humidity, etc.), cargo attributes, and other cargo identification information, etc. The acquisition method can be obtained by scanning the electronic label on the container through the code scanning d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com