High-performance porous pavement mixture and normal-temperature preparation method thereof

A mixture, high-performance technology, used in ceramic products, other household appliances, applications, etc., can solve problems such as insufficient performance, porous pavement mixture cannot be constructed at room temperature, etc., to achieve excellent mechanical properties, excellent performance, durability and compatibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

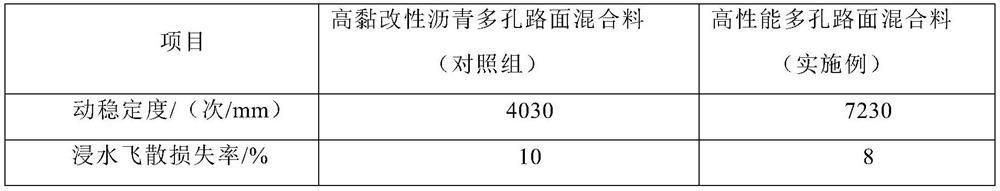

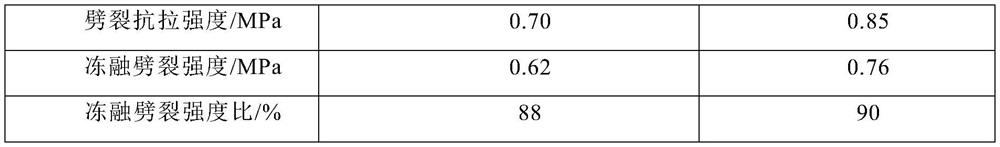

Examples

Embodiment 1

[0035] A kind of high-performance porous pavement mixture of the present invention, described high-performance porous pavement mixture is made up of the following components in parts by weight:

[0036] 100 pieces of mineral material,

[0037] 20 parts of water-based polyurethane emulsion,

[0038] Emulsified asphalt 13 parts.

[0039] The mineral material is composed of coarse aggregate, fine aggregate and filler; the coarse aggregate is basalt, and the fine aggregate and filler are limestone.

[0040] The weight ratio of the coarse aggregate, fine aggregate and filler is 85:10:8, and the gradation meets the gradation requirement of porous pavement.

[0041] The particle diameter of the coarse aggregate is >4.75mm, the particle diameter of the fine aggregate is ≤4.75mm, and the particle diameter of the filler is ≤0.075mm.

[0042] The emulsified asphalt is non-ionic emulsified asphalt.

[0043] The water-based polyurethane emulsion is an emulsion of water-based polyuretha...

Embodiment 2

[0052] The difference between embodiment 2 and embodiment 1 is: a kind of high-performance porous pavement mixture of the present invention, described high-performance porous pavement mixture is made up of the following components in parts by weight:

[0053] 100 pieces of mineral material,

[0054] 15 parts of water-based polyurethane emulsion,

[0055] Emulsified asphalt 10 parts.

[0056] The coarse aggregate is diabase.

[0057] The weight ratio of the coarse aggregate, fine aggregate and filler is 75:20:3, and the gradation meets the gradation requirement of porous pavement.

[0058] In order to control the water content of the mixture, the emulsified asphalt is commercially available cationic emulsified asphalt, and the solid content of the emulsified asphalt needs to be ≥ 50%.

[0059] The water-based polyurethane emulsion is a dispersion liquid of water-based polyurethane, and its solid content is 50%.

[0060] The aqueous polyurethane emulsion is a linear molecula...

Embodiment 3

[0068] The difference between embodiment 3 and embodiment 1 is: a kind of high-performance porous pavement mixture of the present invention, described high-performance porous pavement mixture is made up of the following components in parts by weight:

[0069] 100 pieces of mineral material,

[0070] 18 parts of water-based polyurethane emulsion,

[0071] Emulsified asphalt 15 parts.

[0072] The weight ratio of the coarse aggregate, fine aggregate and filler is 80:26:5, and the gradation meets the gradation requirements of porous pavement.

[0073] The emulsified asphalt is cationic emulsified asphalt.

[0074] The water-based polyurethane emulsion is an emulsion of water-based polyurethane, and its solid content is 30%.

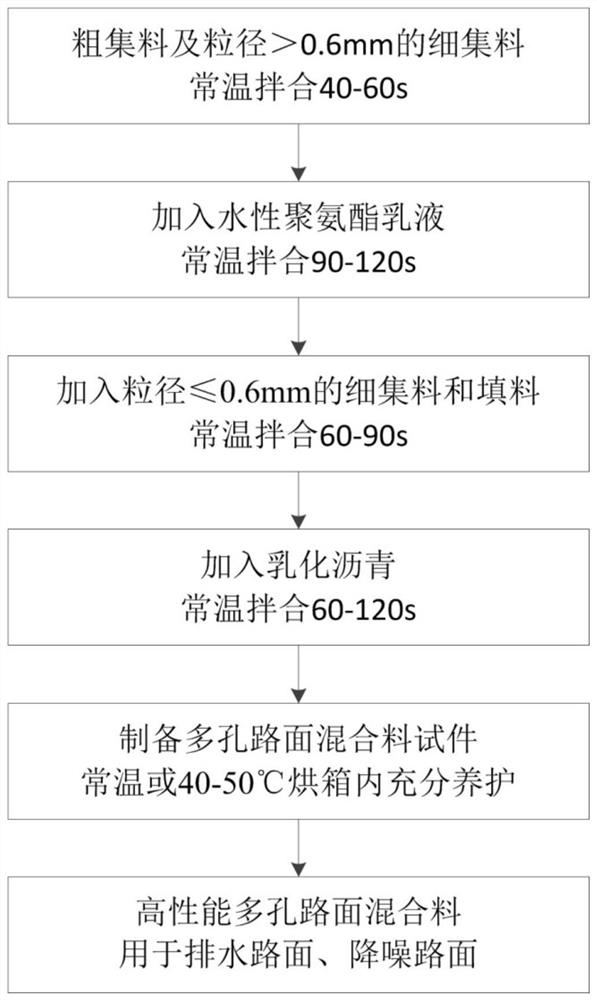

[0075] The present invention also provides a method for preparing the above-mentioned high-performance porous pavement mixture at normal temperature, comprising the following steps:

[0076] In step (1), the coarse aggregate and the fine aggregate with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com