Modified aggregate as well as preparation method and application thereof

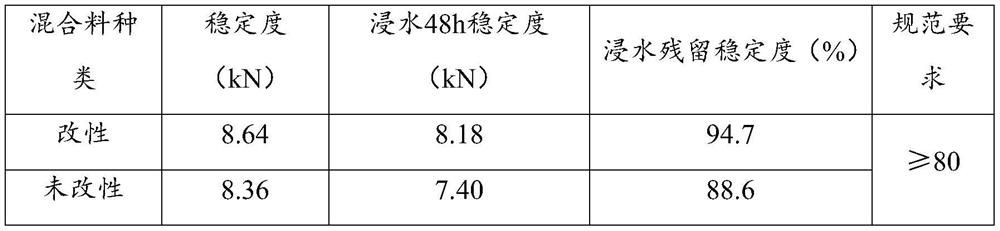

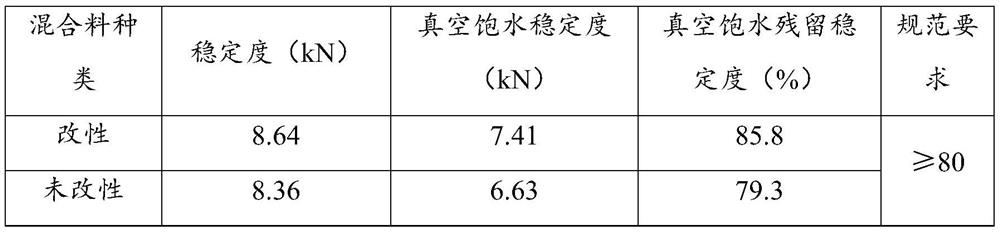

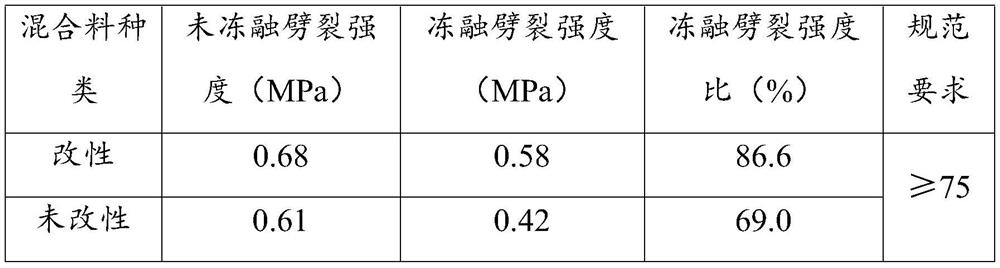

An aggregate and modification technology, applied in the field of modified aggregate and its preparation, can solve the problems of reduced strength and fatigue resistance of the mixture, easy segregation, poor thermal stability, etc., and achieves the effect of good water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] This specific embodiment proposes a kind of preparation method of modified aggregate, comprising the following steps:

[0021] The ethoxysilane coupling agent aqueous solution is 2%-3% of the mass of the aggregate, and the ethoxysilane coupling agent aqueous solution is sprayed on the aggregate surface; wherein, the ethoxysilane coupling agent aqueous solution contains ethoxy The volume concentration of the silane coupling agent is 0.1-1%, further, the volume concentration of the ethoxysilane coupling agent is preferably 0.5%; the aggregate includes one or more of crushed stones, pebbles and sand kind;

[0022] The modified aggregate is obtained by curing the aggregate sprayed with an ethoxysilane coupling agent at 150-180° C. for 2-3 hours. Treating the aggregate at this temperature can improve the curing efficiency of the ethoxysilane coupling agent on the aggregate.

[0023] This specific embodiment also includes a modified aggregate prepared by the above preparati...

Embodiment 1

[0034] A preparation method of modified aggregates, comprising the following steps:

[0035] (1) Spraying the aqueous solution of ethoxysilane coupling agent: prepare an aqueous solution of ethoxysilane coupling agent with a volume fraction of 0.5%, and put the solution into a watering can after standing at room temperature for 20 minutes. Then, according to the requirements of the test specification, weigh a certain mass of aggregate and pour it into an enamel plate, then evenly spray the solution on the surface of the aggregate with 2% of the mass of the aggregate, and stir evenly with a small shovel.

[0036] (2) Dry and cure the modified aggregates: turn on the oven, set the temperature to 170°C, then place the aggregates sprayed with ethoxysilane coupling agent in the oven, and dry and cure for 2 hours.

Embodiment 2

[0038] A preparation method of modified aggregates, comprising the following steps:

[0039] (1) Spraying the aqueous solution of ethoxysilane coupling agent: prepare an aqueous solution of ethoxysilane coupling agent with a volume fraction of 0.5%, and put the solution into a watering can after standing at room temperature for 20 minutes. Then, according to the requirements of the test specification, weigh a certain mass of aggregate and pour it into an enamel plate, then evenly spray the solution on the surface of the aggregate with 3% of the mass of the aggregate, and stir evenly with a small shovel.

[0040] (2) Drying and curing the modified aggregate: turn on the oven, set the temperature to 150°C, then place the aggregate sprayed with ethoxysilane coupling agent in the oven, and dry and cure for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com