Lignin-containing organic-inorganic compound fertilizer prepared by ammonia-acid method as well as ammonia-acid production method

A technology of lignin and compound fertilizer, applied in fertilizer forms, fertilization devices, fertilizer mixtures, etc., to achieve the effects of reducing production costs, enhancing crop resistance, and reducing the addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

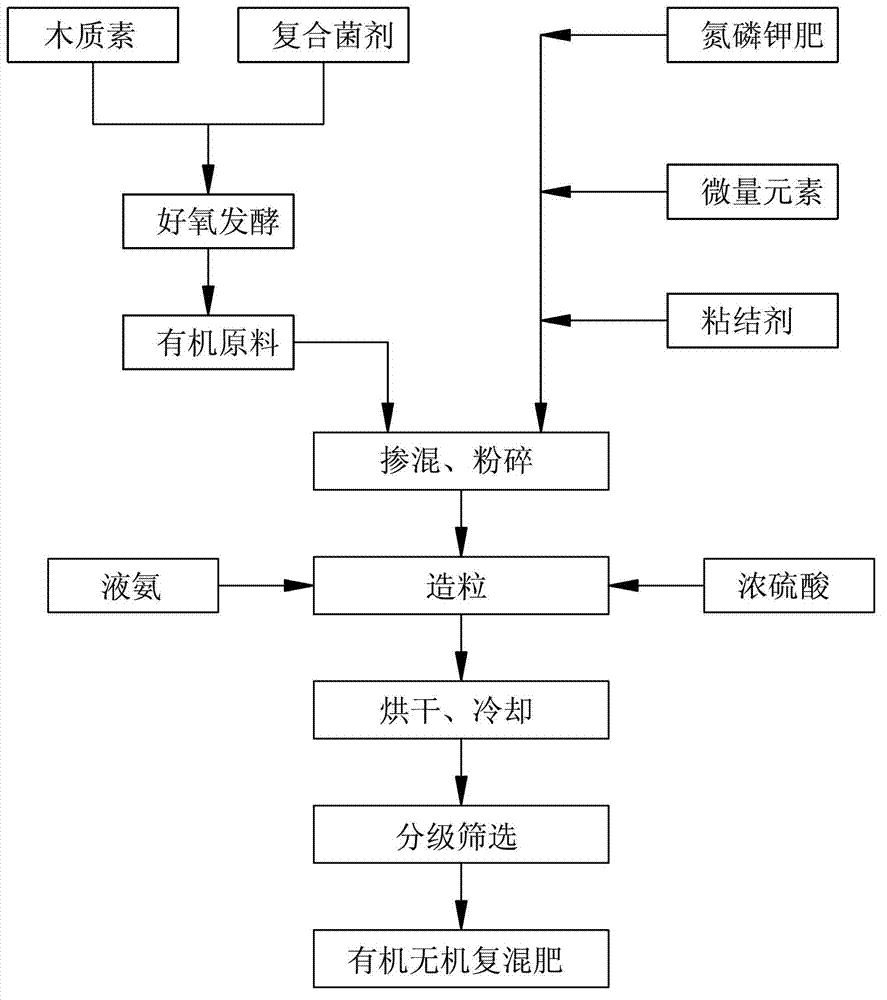

[0022] The method for producing the lignin-containing organic-inorganic compound fertilizer by the amino acid method is as follows:

[0023] (1) Take 2000kg of lignin and 40kg of compound bacterial agent (produced by Shandong Buuoda Biological Engineering Co., Ltd.) and fully mix, of which the compound bacterial agent includes: 6kg of photosynthetic bacteria, 2kg of actinomycetes, 4kg of yeast, and 8kg of phosphate solubilizing bacteria , Potassium-solving bacteria 8kg, nitrogen-fixing bacteria 12kg. Adjust the pH value of the material so that 7≤pH≤8, the material is moderately alkaline and easy to ferment, adjust the porosity of the material with sawdust or plant straw as needed, and then carry out forced aerobic static stack aerobic fermentation, and wait for the material to The temperature rises to 60°C and lasts for more than 7 days, and after the temperature is automatically lowered to 35°C, the decomposing and fermentation cycle is completed, and the powdery material is ...

Embodiment 2

[0028] The method for producing the lignin-containing organic-inorganic compound fertilizer by the amino acid method is as follows:

[0029] (1) Fully mix 2500kg of lignin with 50kg of compound bacteria agent (produced by Shandong Buuoda Biological Engineering Co., Ltd.), in which the compound bacteria agent includes: 7.5kg of photosynthetic bacteria, 2.5kg of actinomycetes, 5kg of yeast, phosphorus solubilizer 10kg of bacteria, 10kg of potassium-dissolving bacteria, and 15kg of nitrogen-fixing bacteria. Adjust the pH value of the material so that 7≤pH≤8, the material is moderately alkaline and easy to ferment, adjust the porosity of the material with sawdust or plant straw as needed, and then carry out forced aerobic static stack aerobic fermentation, and wait for the material to The temperature rises to 55°C and lasts for more than 8 days, and after the temperature is automatically lowered to 40°C, the decomposing and fermentation cycle is completed, and the powdery material...

Embodiment 3

[0034] The method for producing the lignin-containing organic-inorganic compound fertilizer by the amino acid method is as follows:

[0035] (1) Take 3000kg of lignin and 60kg of compound bacterial agent (produced by Shandong Buuoda Biological Engineering Co., Ltd.) and fully mix, in which the compound bacterial agent includes: 9kg of photosynthetic bacteria, 3kg of actinomycetes, 6kg of yeast, 12kg of phosphate solubilizing bacteria , Potassium-solving bacteria 12kg, nitrogen-fixing bacteria 18kg. Adjust the pH value of the material so that 7≤pH≤8, the material is moderately alkaline and easy to ferment, adjust the porosity of the material with sawdust or plant straw as needed, and then carry out forced aerobic static stack aerobic fermentation, and wait for the material to The temperature rises to 65°C and lasts for more than 6 days, and after the temperature is automatically lowered to 30°C, the decomposing and fermentation cycle is completed, and the powdery material is ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com