Degradable food packaging material and preparation method thereof

A technology for food packaging and raw materials, applied in the field of packaging materials, can solve the problems of high dependence on staff, no recycling value, and inability to degrade food packaging materials, and achieve the effect of increasing overall toughness and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

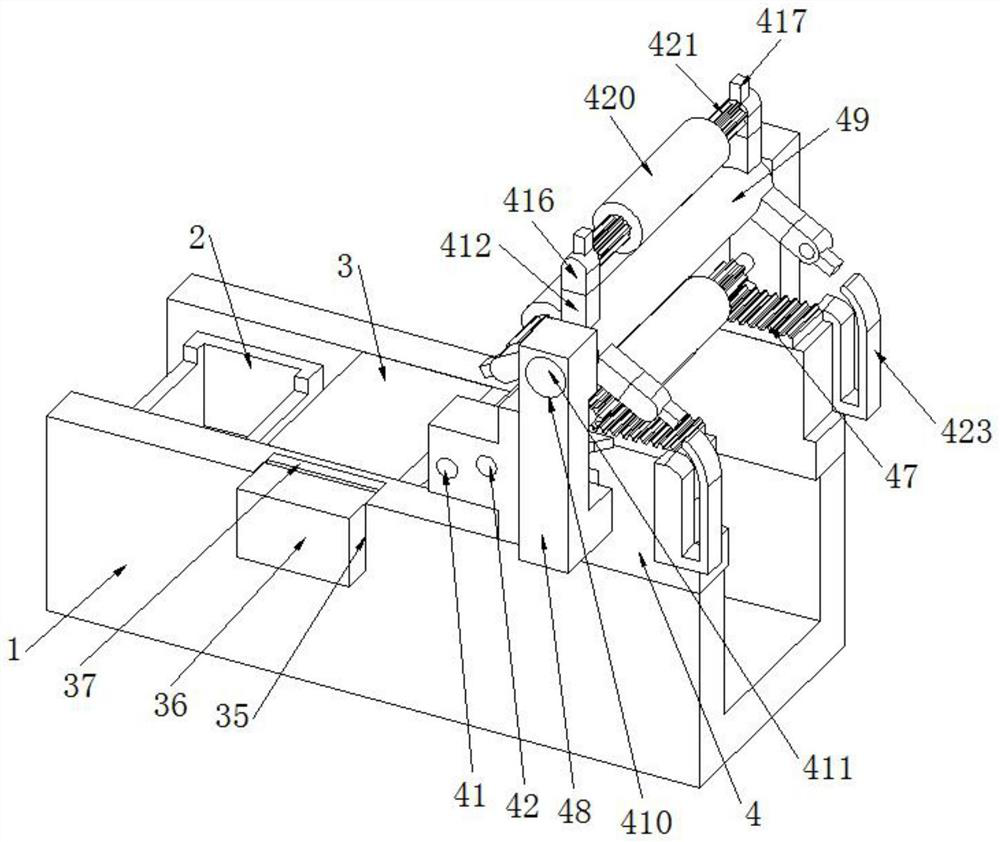

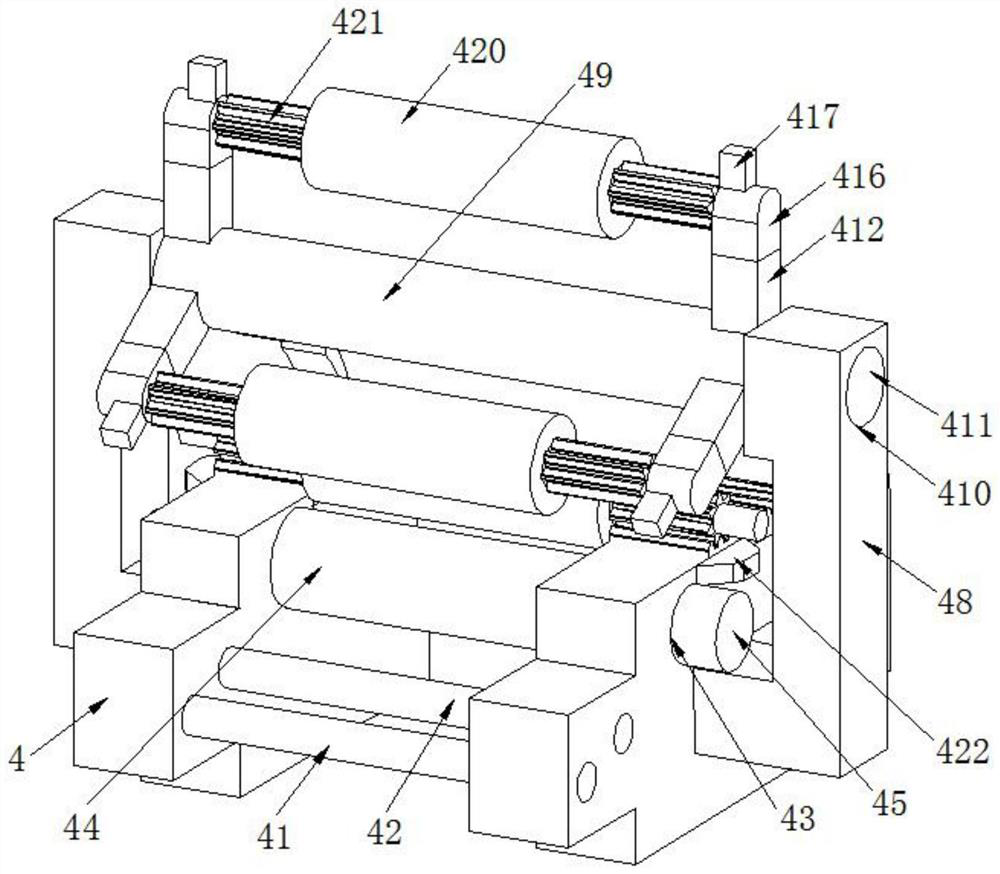

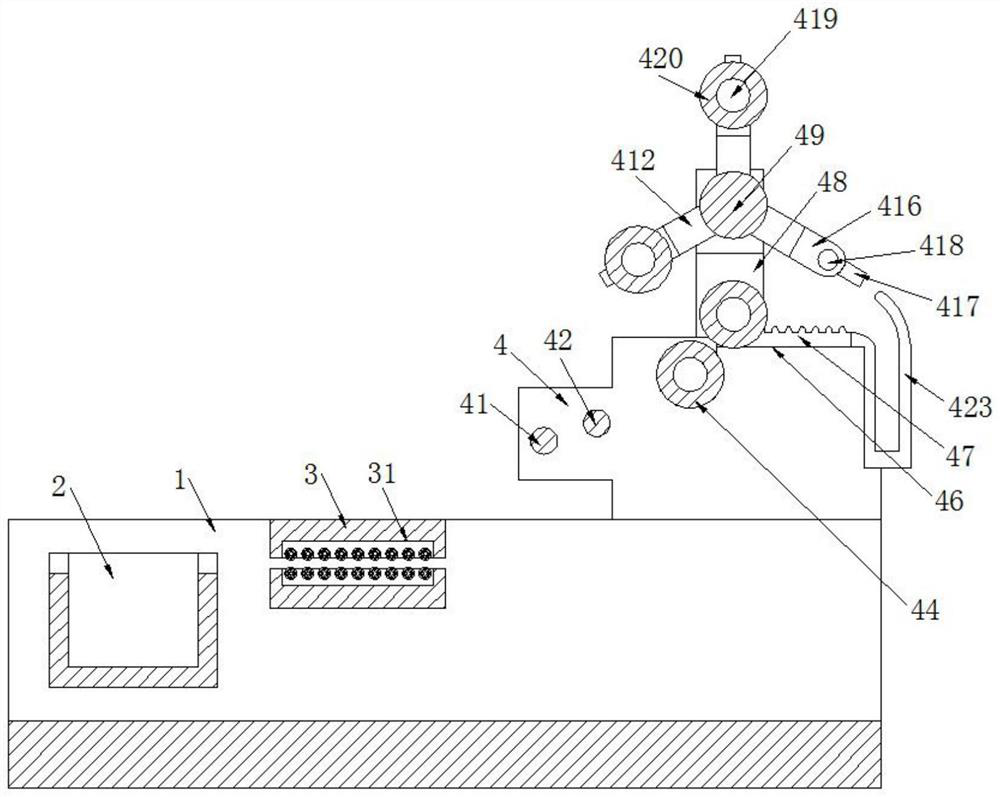

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0030] refer to Figure 1-6 , a degradable food packaging material and a preparation method thereof, comprising preparation of raw materials including polyvinyl alcohol, starch, commercial peach gum, gelatin, water, egg curd, chitin, polylactic acid and flax.

[0031] The mass percent content of each component is respectively: the weight portion of polyvinyl alcohol is 30%, the weight portion of starch is 20%, the weight portion of commercial peach gum is 8%, the weight portion of gelatin is 12%, the weight portion of water 8%, the weight portion of egg curd is 5%, the weight portion of chitin is 8%, the weight portion of polylactic acid is 4%, and the weight portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com