A kind of mold high temperature resistant pvd coating and preparation method thereof

A technology of high temperature resistance and mold, which is applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of mold scrapping and inability to be reused, and achieve the goal of reducing yield loss and production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

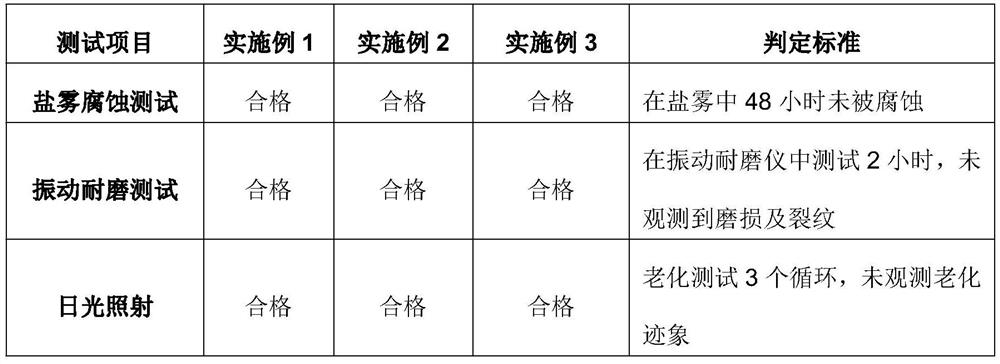

Examples

preparation example Construction

[0022] The present invention also provides a method for preparing a mold high temperature resistant PVD coating, comprising the steps of:

[0023] (1) Purify the surface of the mold, finely grind and polish the corroded or scratched mold to make the mold surface reach a mirror state, and then use acetone and alcohol to ultrasonically clean and dry the mold;

[0024] (2) Use the arc power bombardment method to make a layer of AlCrN on the mold surface; the bias voltage of the arc power bombardment method is controlled at 220~360V, and the time is controlled at 5~8 minutes; preferably, the arc power bombardment method bias is controlled at 280V, the time is controlled at 6 minutes;

[0025] (3) Using vapor deposition method to use SiO2 and TiN to carry out intermediate multi-layer transition on the bottom layer; the equipment vacuum degree of the vapor deposition method is required to be above 3×10-5Torr, the bias value is set at 70V-120V, and the target material The current is...

Embodiment 1

[0029] A method for preparing a mold high temperature resistant PVD coating:

[0030] (1) Purify the surface of the mold, finely grind and polish the corroded or scratched mold to make the mold surface reach a mirror state, and then use acetone and alcohol to ultrasonically clean and dry the mold;

[0031] (2) use the arc power bombardment method to make a layer of AlCrN on the mold surface; the arc power bombardment method bias is controlled at 220V, and the time is controlled at 5 minutes;

[0032] (3) Use vapor deposition method to use SiO2 and TiN to carry out intermediate multi-layer transition on the bottom layer; the vacuum degree of the equipment of the vapor deposition method is required to be 3 × 10-5Torr, the bias value is set at 70V, and the target current is set In 4A; the number of layers in the middle layer is controlled at 10 layers; the single-layer deposition time of the vapor deposition method is controlled at 15 minutes;

[0033] (4) Put a protective layer...

Embodiment 2

[0035] A method for preparing a mold high temperature resistant PVD coating:

[0036] (1) Purify the surface of the mold, finely grind and polish the corroded or scratched mold to make the mold surface reach a mirror state, and then use acetone and alcohol to ultrasonically clean and dry the mold;

[0037] (2) use the arc power bombardment method to make a layer of AlCrN on the mold surface; the arc power bombardment method bias is controlled at 280V, and the time is controlled at 6 minutes;

[0038] (3) Use vapor deposition method to use SiO2 and TiN to carry out intermediate multi-layer transition on the bottom layer; the equipment vacuum degree of the vapor deposition method is required to be 4×10-5Torr, the bias value is set at 90V, and the target current is set In 6A; the number of layers in the middle layer is controlled at 11 layers; the single-layer deposition time of the vapor deposition method is controlled at 20 minutes;

[0039] (4) Put a protective layer CrN on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com