Vacuum silver coated glass and preparation process thereof

A vacuum silver plating and preparation technology, applied in the direction of glass/slag layered products, chemical instruments and methods, layered products, etc., can solve the problems of general anti-oxidation and water vapor resistance, low reflectivity, and easy oxidation of the film layer etc. to achieve better appearance, soft and bright surface gloss, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

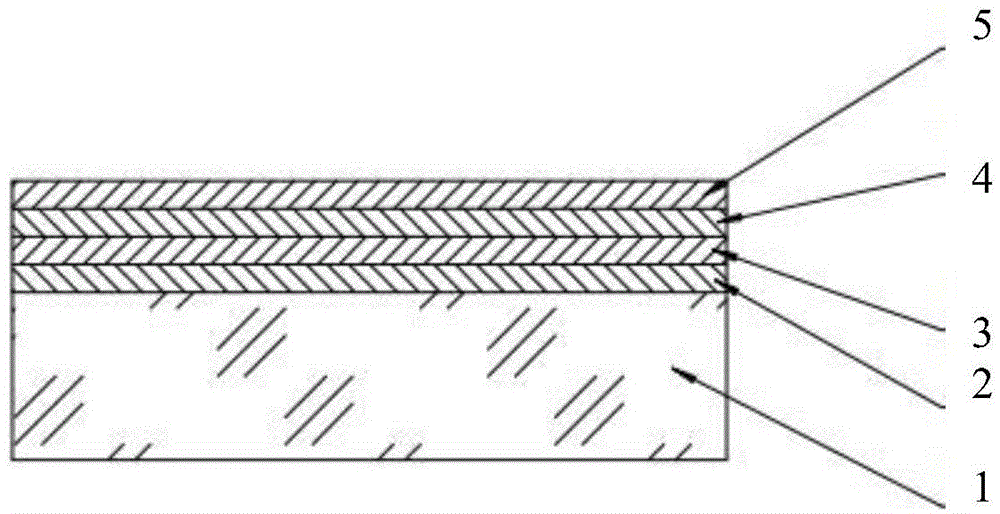

[0025] Such as figure 1 As shown, the vacuum silver-coated glass of the present invention includes a glass substrate 1, and a first reflective film layer 2, a second reflective film layer 3, and a first protective film layer sequentially placed on the surface of the glass substrate 4 and the second protective film layer 5. The first reflective film layer 2 is a pure silver layer, the second reflective film layer 3 is a pure aluminum layer, and the first protective film layer 4 is a pure titanium layer. The second protective film layer 5 is a titanium oxide layer.

[0026] In the present invention, the thickness of the first reflective film layer 2 is in the range of 0.1 to 0.4 microns, and the thickness of the second reflective film layer 3 is in the range of 0.6 to 1.6 microns.

[0027] The thickness of the first protective film layer 4 ranges from 0.05 to 0.1 microns, and the thickness of the second protective film layer 5 ranges from 0.02 to 0.1 microns.

[0028] In addition, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com