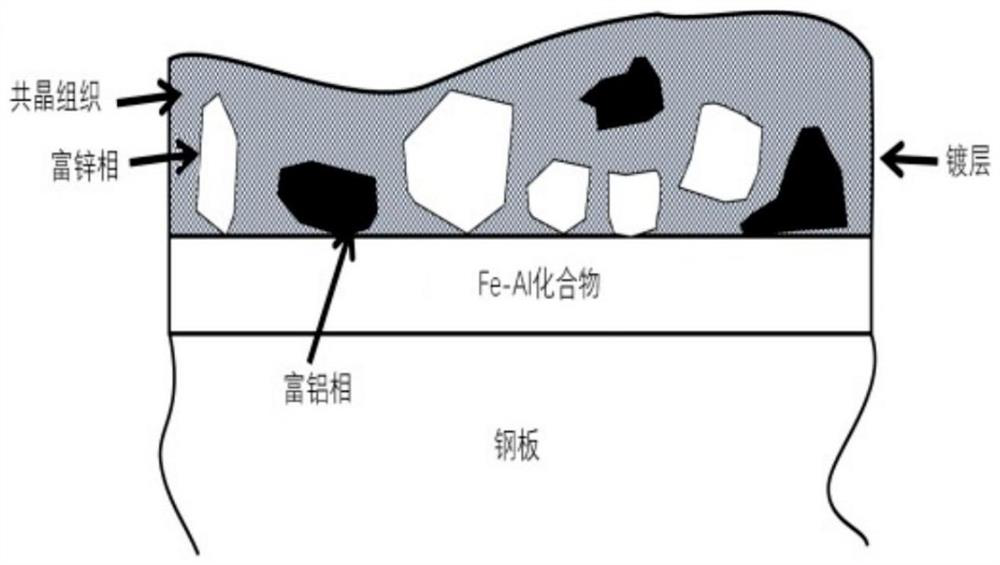

Hot-dip galvanized coated steel sheet and preparation method thereof

A technology of coated steel sheet and hot-dip galvanizing, which is applied in hot-dip galvanizing process, coating, metal material coating process, etc., and can solve the problem that the corrosion resistance and coating thickness cannot be balanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

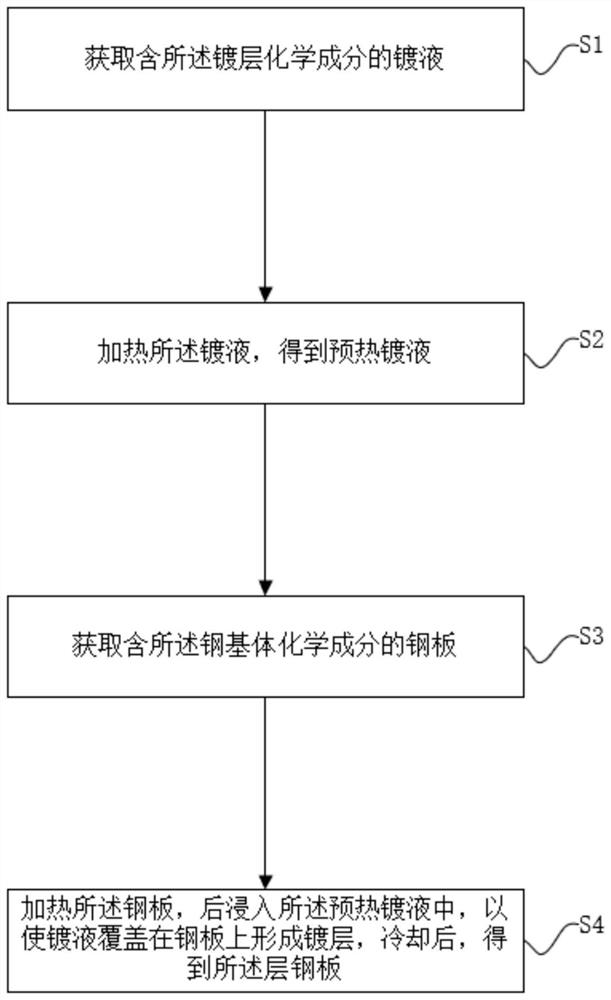

[0048] Second aspect, such as figure 2 Shown, the application provides a kind of preparation method of hot-dip galvanized steel plate, and described preparation method comprises:

[0049] S1. Obtain a plating solution containing the chemical composition of the coating;

[0050] S2. heating the plating solution to obtain a preheated plating solution;

[0051] S3. Obtain a steel plate containing the chemical composition of the steel matrix;

[0052] S4. Heating the steel plate, and then immersing it in the preheated plating solution, so that the plating solution covers the steel plate to form a coating, and after cooling, the steel plate of the layer is obtained.

[0053] As an optional embodiment, the temperature of the preheated plating solution is within 400°C-480°C.

[0054] In this application, the effect of limiting the temperature of the preheating bath to 400°C-480°C is that the temperature of the bath reaches the temperature range capable of reacting with the steel ...

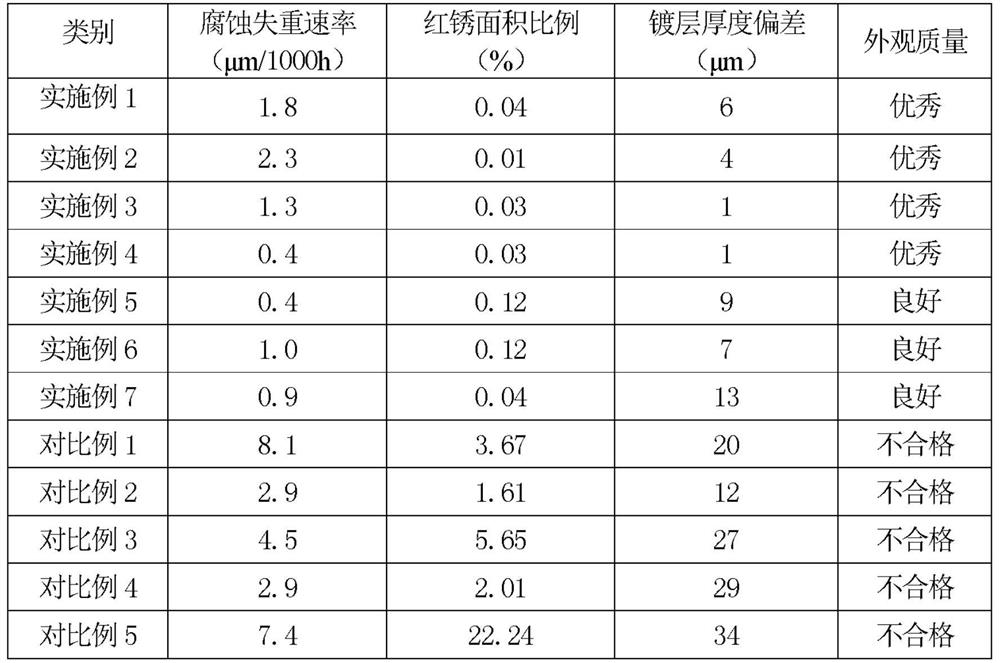

Embodiment 1

[0067] Select a 2mm steel plate, the chemical composition of the steel matrix includes: C: 0.05%, Mn: 0.02%, Si: 0.3%, Cr: 0.02%, B: 0.0001%, Al: 0.05% in terms of mass fraction;

[0068] The chemical composition of the coating includes: Mg: 1%, Al: 5%, rare earth elements: 0.02%, and the rest is Zn and unavoidable impurities in terms of mass fraction;

[0069] Among the rare earth elements, the mass fraction of La is 0%, the mass fraction of Ce is 0%, the mass fraction of Er is 0.02%, and the mass fraction of Y is 0%;

[0070] The equivalent diameter of the aluminum-rich phase is 5 μm;

[0071] In the preparation method, the temperature of the preheating bath is 480°C;

[0072] In heating the steel plate, the heating temperature is controlled to be 10°C lower than the temperature of the preheated plating solution, so the heating temperature is 470°C;

[0073] In heating the steel plate, the atmosphere temperature at the leakage point is -40°C;

[0074] The average surface ro...

Embodiment 2

[0076] Select a 2.4mm steel plate, the chemical composition of the steel matrix includes: C: 0.1%, Mn: 0.8%, Si: 0.4%, Cr: 0.1%, B: 0.0004%, Al: 0.4% in terms of mass fraction;

[0077] The chemical composition of the coating includes: Mg: 1%, Al: 6%, rare earth elements: 0.101%, and the rest is Zn and unavoidable impurities in terms of mass fraction;

[0078] Among the rare earth elements, the mass fraction of La is 0%, the mass fraction of Ce is 0.001%, the mass fraction of Er is 0%, and the mass fraction of Y is 0.1%;

[0079] The equivalent diameter of the aluminum-rich phase is 5 μm;

[0080] In the preparation method, the temperature of the preheating bath is 425°C;

[0081] In heating the steel plate, the heating temperature is controlled to be 15°C lower than the temperature of the preheated plating solution, so the heating temperature is 410°C;

[0082] In heating the steel plate, the atmosphere temperature at the leakage point is -50°C;

[0083] The surface averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface average roughness | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com