Pulsed arc particle planting method for particle mixed powder-cored welding wire

A pulsed arc, planting method technology, applied in the direction of arc welding equipment, welding medium, welding equipment, etc., to achieve a wide range of options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

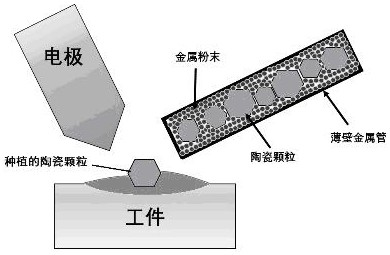

[0027] Using 304 stainless steel as the substrate, the surface to be planted is polished and smoothed to remove scale and other impurities, and after scrubbing with absolute alcohol, it is dried with hot air for later use.

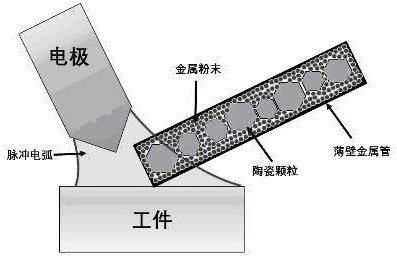

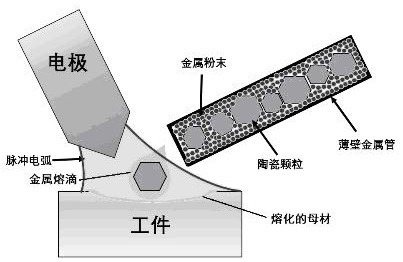

[0028] A 304 stainless steel tube with an inner diameter of 3 mm and a wall thickness of 0.2 mm is used as the outer skin of the welding wire. SiC coarse particles and MCrAlY alloy powder are mixed with a rosin-based synthetic resin binder at a mass ratio of 5:1, and packed into the stainless steel tube to fill it tightly. SiC coarse particle size is 1000~3000μm, MCrAlY alloy powder particle size is 45~105μm, and the port is sealed.

[0029] Set welding parameters: pulse current 50A, pulse frequency 1Hz, pulse width 50ms.

[0030] Put the prepared powder-cored wire mixed with particles flat on the surface of the workpiece, and use DC positive connection, that is, the workpiece is connected to the positive electrode, and the tungsten electrode is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com