A local defect whisker or flake reinforcement repair method and repair coating of carbon/carbon composite coating

A carbon composite material, local defect technology, applied in the repair coating of reinforced composite structure and its related fields, can solve the problems of inconvenient on-site operation, inability to repair in layers, difference in coating performance, etc., to improve consistency, reduce Equipment dependence, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0048] The method for repairing local defect whiskers or flakes of carbon / carbon composite material coatings provided by the present invention comprises the following steps:

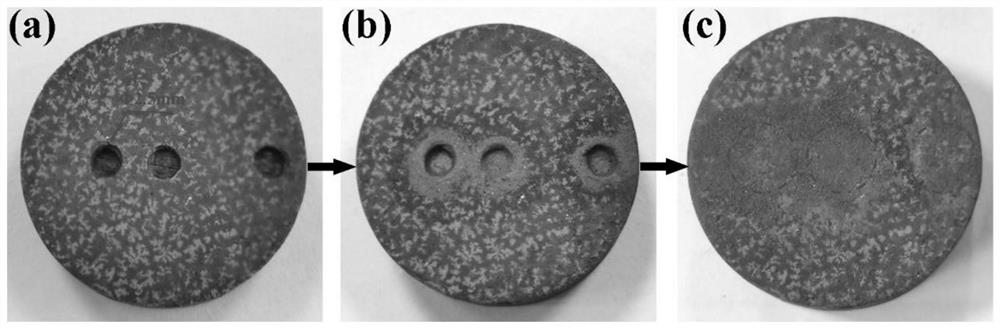

[0049] (1) First, clean up the local defects (natural damage or man-made damage) of the carbon / carbon composite coating, such as figure 1 As shown in (a), the diameter of the surface depression at the damaged part is about 2.5mm. Use 400-grit sandpaper to polish the peeled surface of the coating, then use ethanol to clean the peeled surface of the coating, and finally use a handheld heating device to bake at 80 °C. Dry;

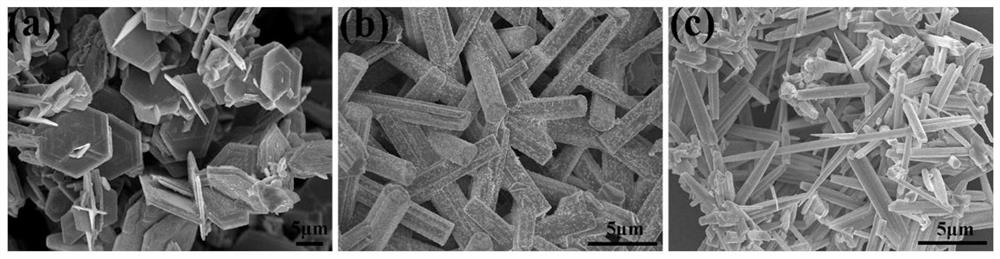

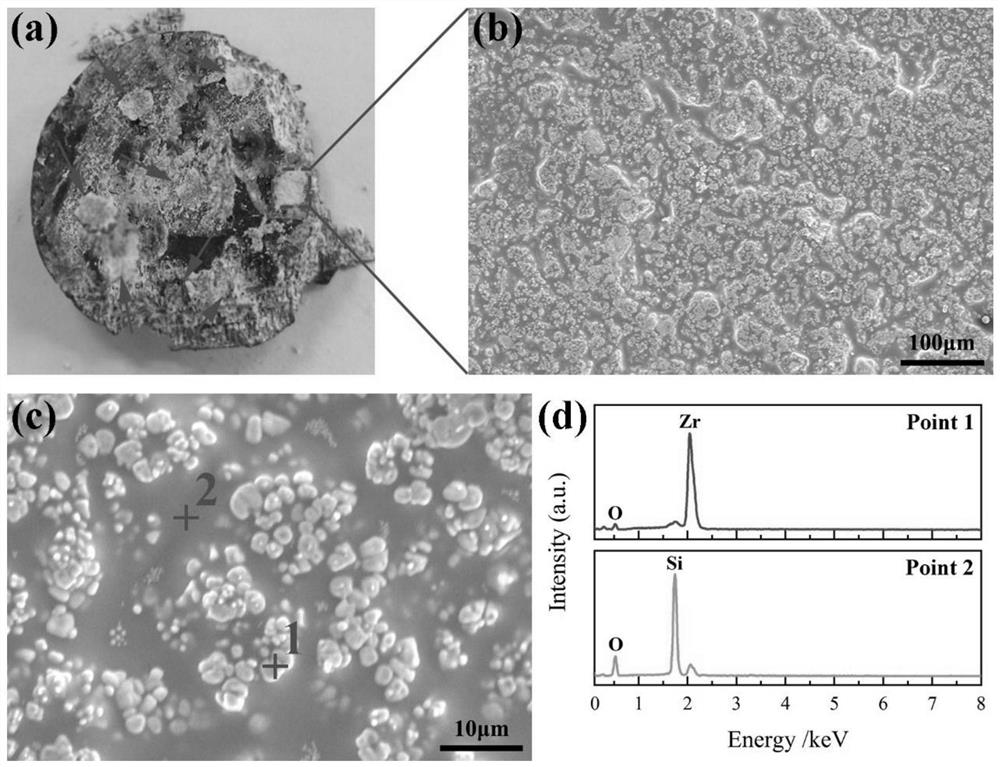

[0050] (2) Mix 300 mesh silicon powder and liquid polycarbosilane in a mass ratio of 4:5, and then magnetically stir evenly to obtain the coating slurry of the inner coating, and then use the brushing method to brush the slurry on the surface where the coating has fallen off. , using hand-held heating equipment to cure at 250 ℃ for 20min, to obtain the inner coating transition layer su...

specific Embodiment 2

[0055] The method for repairing local defect whiskers or sheet-like reinforcement of the carbon / carbon composite material coating provided in the embodiment of the present invention and the repairing coating are basically the same as those in Embodiment 1, and the differences are:

[0056] (1) First, use 400-grit sandpaper to polish the surface of the local defect (damage) of the carbon / carbon composite coating, and then use ethanol to clean the surface of the coating. Finally, use a handheld heating device at 80 ℃ drying;

[0057] (2) Mix 300 mesh silicon powder and liquid polycarbosilane in a mass ratio of 4:6, stir magnetically evenly to obtain the coating slurry of the inner coating, and then apply the slurry to the surface where the coating falls off by brushing. , using a hand-held heating device to cure at 250 ° C for 20 min to obtain an inner coating;

[0058] (3) The drying and curing transition layer is subjected to low temperature plasma treatment for 4 minutes to im...

specific Embodiment 3

[0063] The local defect whisker or sheet-like reinforcement repair method and repair coating of the carbon / carbon composite material coating provided in the embodiment of the present invention are basically the same as those in Embodiments 1 and 2, and the differences are:

[0064] (1) First, use 400-grit sandpaper to polish the surface of the local defect (damage) of the carbon / carbon composite coating, and then use distilled water to clean the surface of the coating. Finally, use a handheld heating device at 80 ℃ drying;

[0065] (2) Mix 300 mesh silicon powder and liquid polycarbosilane in a mass ratio of 4:7, stir magnetically evenly to obtain the coating slurry of the inner coating, and then apply the slurry to the surface where the coating falls off by brushing. , using a hand-held heating device to cure at 250 ° C for 20 min to obtain an inner coating;

[0066] (3) The drying and curing transition layer is subjected to low temperature plasma treatment for 5 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com