A method of preparing carbon-coated aluminum nanoparticles using wire electric explosion method

A nanoparticle, electric explosion technology, applied in metal processing equipment, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as reducing the safety of device operation, and achieve high product generation rate and energy utilization rate. , Simple preparation, less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

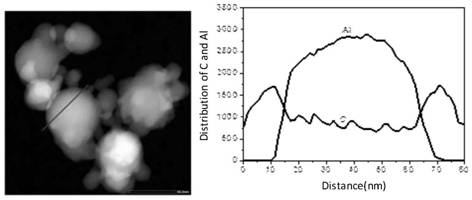

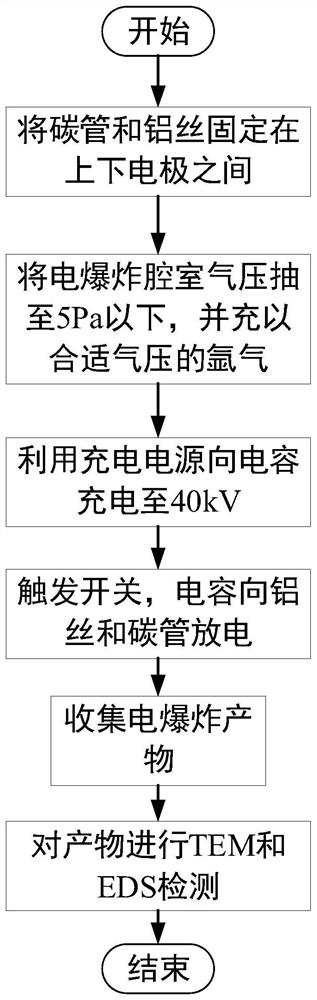

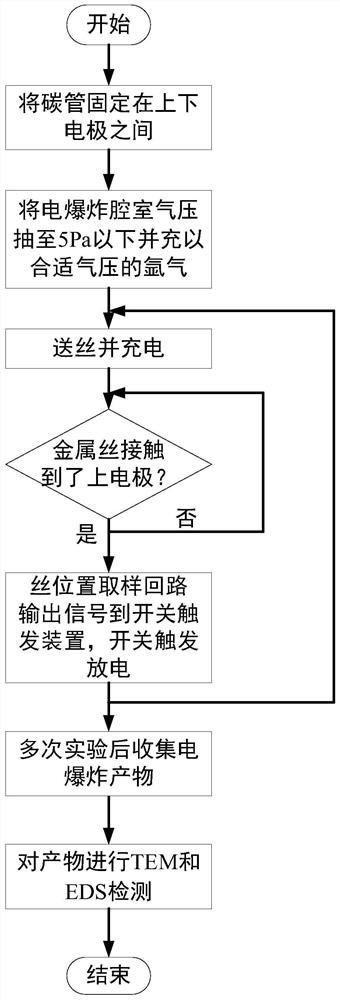

[0044] Example 1 (in single mode)

[0045] Step 1: Place the aluminum wire at the center of the carbon tube 1 with an inner diameter of 14mm, and fix the aluminum wire and the carbon tube 1 on the upper and lower electrodes of the electric explosion chamber;

[0046] Step 2: Seal the electric explosion chamber; after the electric explosion chamber is evacuated to a vacuum, it is filled with argon, and the air pressure is 100kPa;

[0047] Step 3: Charge the capacitor to the set voltage, trigger the switch, and discharge the capacitor through the metal wire 2 and the carbon tube 1;

[0048] Step 4: Place the aluminum wire in the carbon tube 1, and conduct an electric explosion experiment in an inert gas environment to obtain carbon-coated nanoparticles. The diameter of the carbon tube 1 is 14 mm; the argon gas in the electric explosion chamber is discharged, and the nanoparticles It is collected on the microporous filter membrane; multiple electric explosion experiments are car...

Embodiment 2

[0049] Example 2 (in single mode)

[0050] Step 1: Place the aluminum wire at the center of the carbon tube 1 with an inner diameter of 20mm, and fix the aluminum wire and the carbon tube 1 on the upper and lower electrodes of the electric explosion chamber;

[0051] Step 2: Seal the electric explosion chamber; after the electric explosion chamber is evacuated to a vacuum, it is filled with argon, and the air pressure is 100kPa;

[0052] Step 3: Charge the capacitor to the set voltage, trigger the switch, and discharge the capacitor through the metal wire 2 and the carbon tube 1;

[0053] Step 4: Place the aluminum wire in the carbon tube 1, and conduct an electric explosion experiment in an inert gas environment to obtain carbon-coated nanoparticles. The diameter of the carbon tube 1 is 20mm; discharge the argon gas in the electric explosion chamber, and the nanoparticles It is collected on the microporous filter membrane; multiple electric explosion experiments are carried ...

Embodiment 3

[0054] Example 3 (in single mode)

[0055] Step 1: Place the aluminum wire at the center of the carbon tube 1 with an inner diameter of 25mm, and fix the aluminum wire and the carbon tube 1 on the upper and lower electrodes of the electric explosion chamber;

[0056] Step 2: Seal the electric explosion chamber; after the electric explosion chamber is evacuated to a vacuum, it is filled with argon, and the air pressure is 100kPa;

[0057] Step 3: Charge the capacitor to the set voltage, trigger the switch, and discharge the capacitor through the metal wire 2 and the carbon tube 1;

[0058] Step 4: Place the aluminum wire in the carbon tube 1, and conduct an electric explosion experiment in an inert gas environment to obtain carbon-coated nanoparticles. The diameter of the carbon tube 1 is 25 mm; discharge the argon gas in the electric explosion chamber, and the nanoparticles It is collected on the microporous filter membrane; multiple electric explosion experiments are carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com