Nano-silver wrapped one-dimensional linear electrode material and preparation method thereof

An electrode material, nano-silver technology, applied in conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve problems such as high resolution and difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

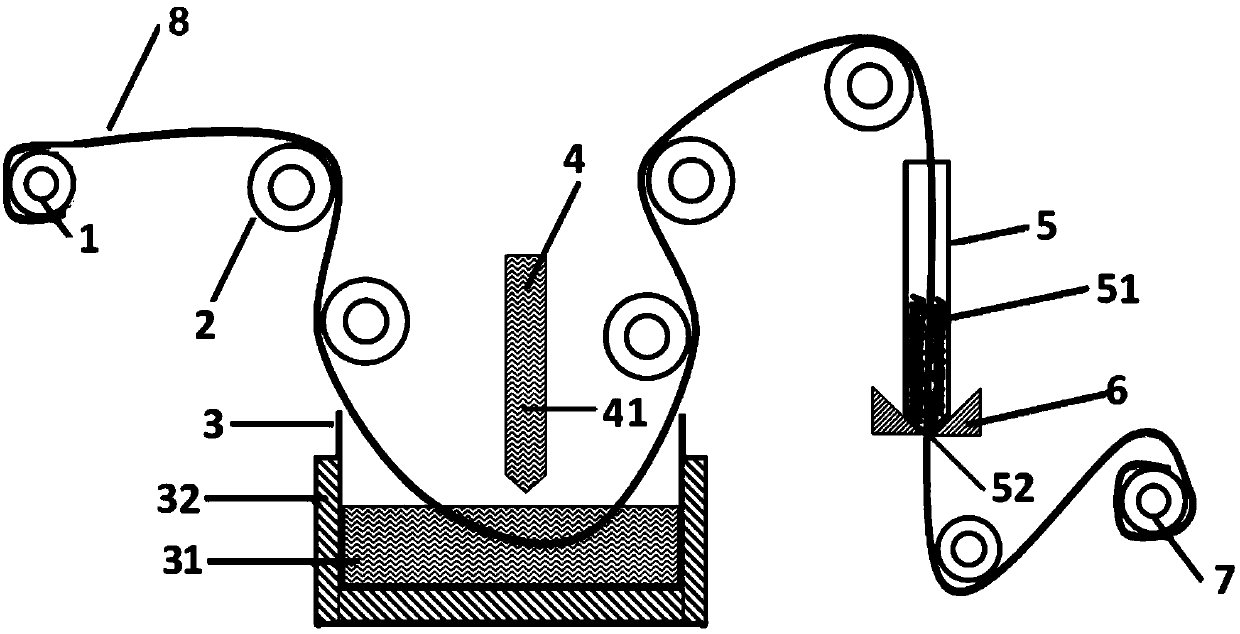

[0091] Choose copper wire with a width and diameter of 10-12μm, in such as figure 1 Wrapping is carried out on the device shown, and it is transported to the online chemical reaction tank by unwinding and rollers, and the reaction precursor solution reacts with the reducing agent, and the electroless plating method is used to prepare 20-50nm thick nano-silver on the surface of the copper wire for the first time The granular layer, wherein the reaction precursor solution is silver nitrate aqueous solution, the reducing agent is lauric acid, and the molar concentration ratio of the two added is 1:5.

[0092] Then, in the silver paste wrapping device, a wire drawing method is used to coat the surface of the material for the second time and then wrap a layer of silver paste material. The proportion of conductive filler in the silver paste material is 82%; the proportion of inorganic paste is 4% bismuth oxide, 1% silicon oxide, and 2% low-melting glass powder; the proportion of org...

Embodiment 2

[0096] The back electrode aluminum for silicon-based solar cell packaging has a bandwidth of 0.3mm and a thickness of 0.02mm. In order to obtain higher conductivity and adhesion, such as figure 1 Wrapping is carried out on the device shown, and it is transported to the online chemical reaction tank by unwinding and rollers, and the reaction precursor solution reacts with the reducing agent, and the surface chemical plating method is used to coat the surface of the 0.1mm wide aluminum foil for the first time. A rough silver film with a thickness of about 50nm, which has strong adhesion. Wherein, the reaction precursor solution is silver sulfate aqueous solution, the reducing agent is ethylene glycol, and the molar concentration ratio of the two is 1:2.

[0097]Then, at the front end of the installation line where the electrode is installed on the aluminum strip, a layer of silver paste material is applied on the surface of the aluminum strip after the second coating by the roll...

Embodiment 3

[0100] Choose copper wire in such as figure 1 Wrapping is performed on the device shown, and it is transported to the online chemical reaction tank by unwinding and rollers, and reacts with the reducing agent through the reaction precursor solution, and uses a chemical replacement reaction to wrap a layer of high-adhesion film after the first coating on the surface of the copper wire. Focus on silver nanoparticles, wherein the reaction precursor solution is silver nitrate aqueous solution, the reducing agent is tetrabutylammonium bromide, and the molar concentration ratio of the two is 1:8.

[0101] Then, in the silver paste wrapping device, a layer of silver paste material is coated on the surface of the material for the second time. The proportion of conductive filler in the silver paste material is 80%, and the conductive filler is silver nanoparticles with a size of 20-50nm; the proportion of inorganic paste is 5% nanometer Ag3Sn; the proportion of organic paste is 15% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com