Fatigue-resistant flame-retardant PC/ABS alloy and preparation method thereof

A technology of fatigue resistance and alloy, which is applied in the field of fatigue resistance flame retardant PC/ABS alloy and its preparation, can solve the problems such as fatigue resistance research of flame retardant PC/ABS materials that have not been seen, and meet the requirements of processing fluidity , excellent flame retardancy, the effect of less terminal hydroxyl content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-6

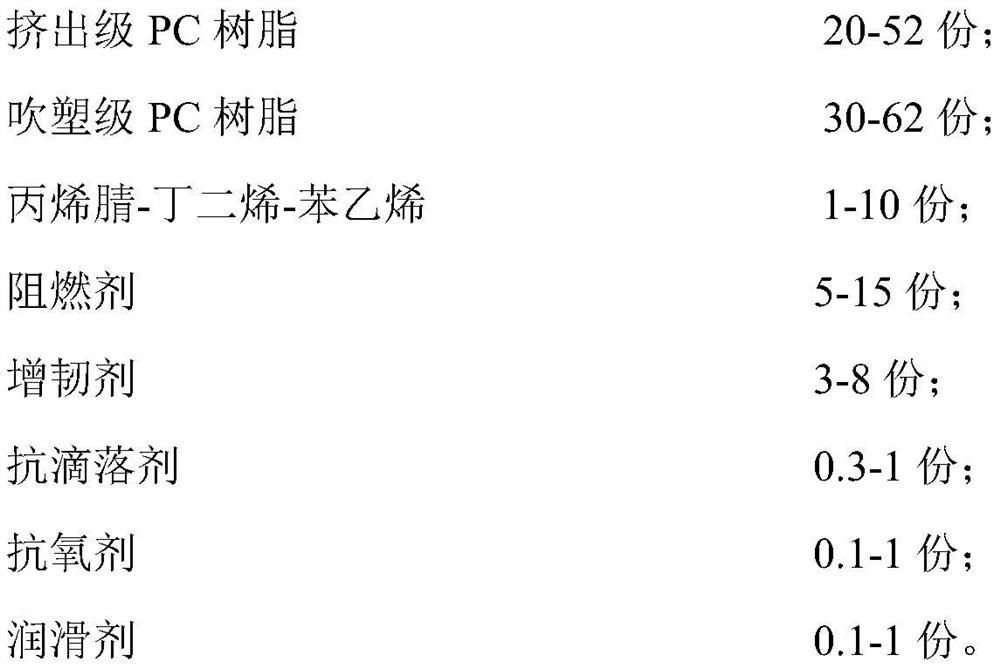

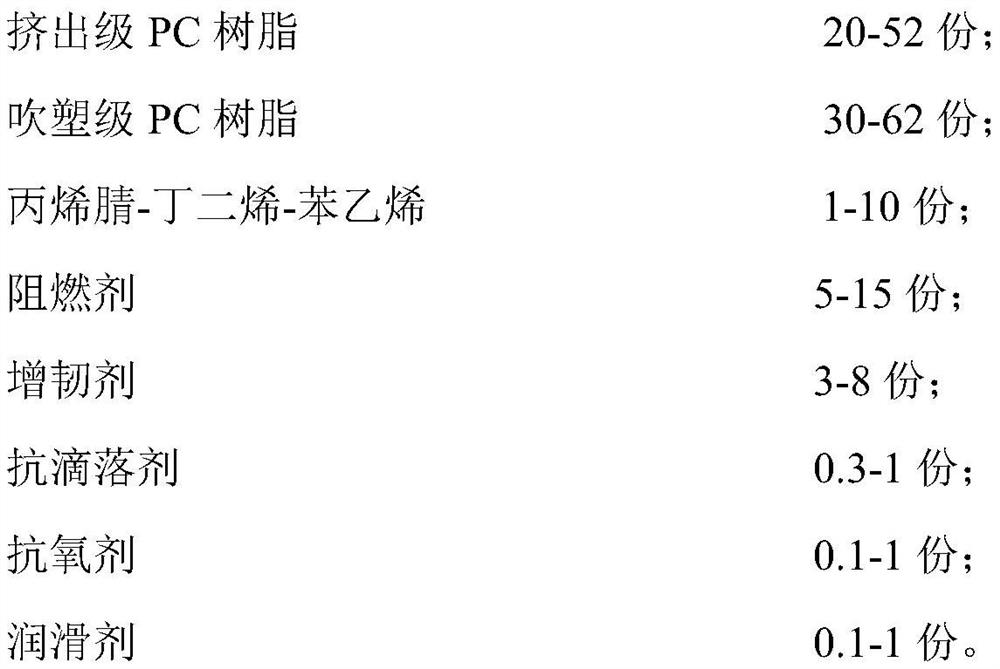

[0037] The alloys of Examples 1-4 and Comparative Examples 1-6 were prepared according to the components and contents in Table 1 respectively.

[0038] Table 1 embodiment 1-4 and comparative example 1-6 each component and component content (by weight)

[0039]

[0040] The alloy of above-mentioned each embodiment and comparative example is prepared by following method:

[0041] The fatigue resistance flame-retardant PC / ABS alloy in embodiment 1-2 is prepared by the following method:

[0042] Put each raw material in a high-speed mixer according to the formula in Table 1 and stir it. After mixing evenly, it is sent into the twin-screw extruder through a metering device. The temperature of the twin-screw extruder is controlled at 230 ° C. Under kneading, the materials are melted and compounded, melted and extruded at a screw speed of 400 r / min, cooled and granulated to obtain a fatigue-resistant flame-retardant PC / ABS alloy composition.

[0043] The fatigue resistance flame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com