Uniform TP316H austenitic stainless steel electroslag ingot composition and structure process method

A technology of austenitic stainless steel and process method, applied in the field of iron and steel metallurgy, can solve the problems of increased Al at the bottom of the steel ingot, longitudinal composition of the steel ingot, uneven structure, etc., and achieve the effect of large slag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

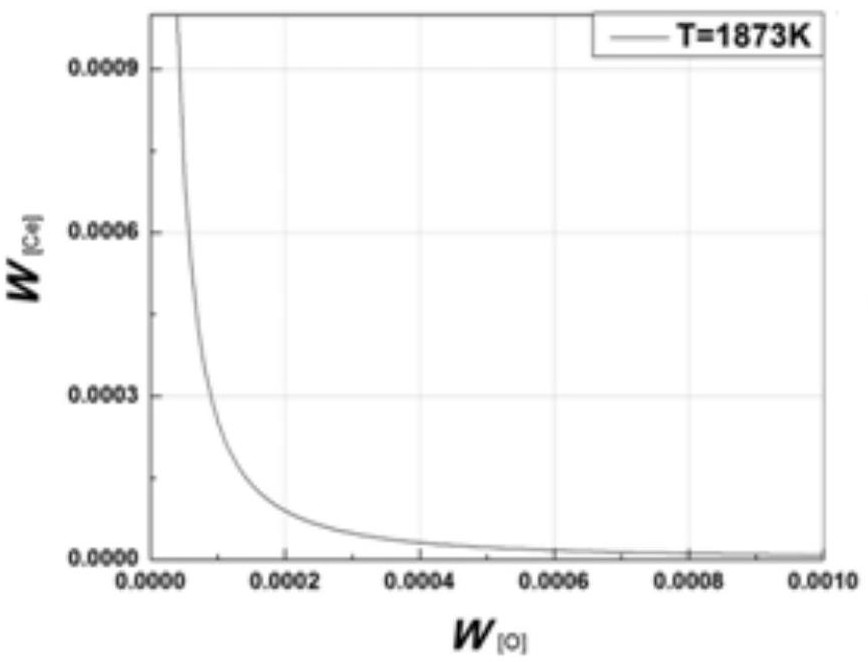

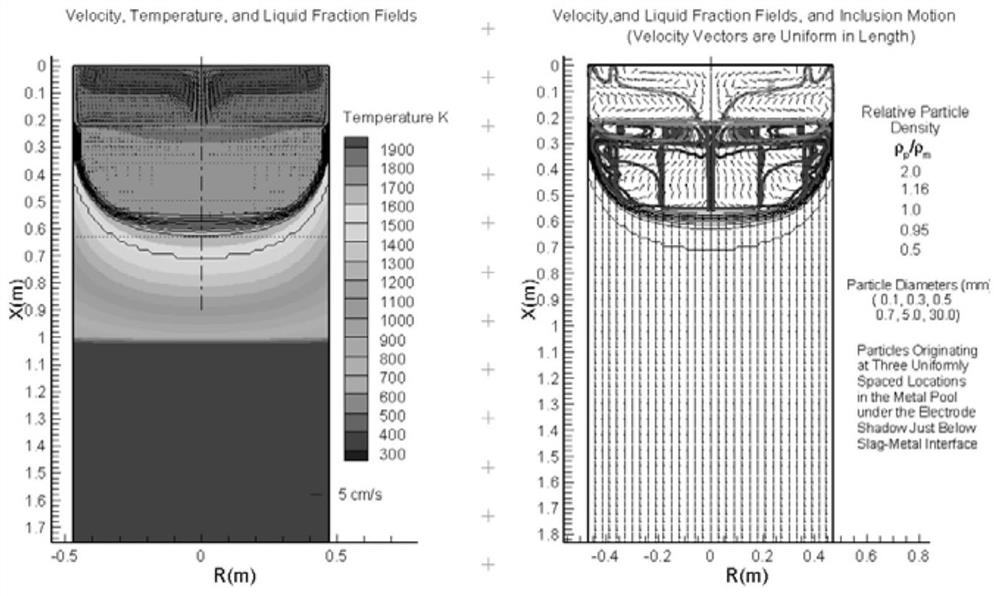

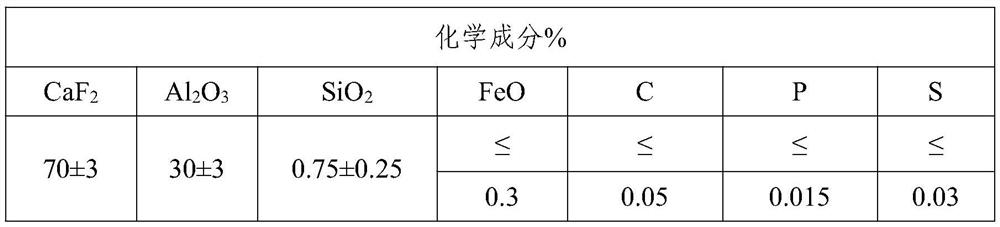

[0024] 1. During the electric furnace smelting process, the carbon content of the steel is controlled, and the P content is reduced below 0.003%. The steel is tapped in the electric furnace, and the silicon, aluminum, barium and calcium are added for pre-deoxidation, and the refining temperature is guaranteed; the refining process adopts the diffusion deoxidation method to reduce the oxygen content and decarburize , To create conditions for reducing inclusions, use VOD to remove C, control the C content at 0.30-0.40%, VD for degassing, and add 150ppm rare earth alloy when the composition and gas content meet the technical requirements. Molten steel with qualified composition and gas content is poured with an argon protection device; impurities on the surface of the electrode billet are removed by grinding to avoid entering the slag pool during electroslag remelting, destroying the slag system, and affecting the oxidizable elements at the bottom of the TP316H steel ingot. burn o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com