Low-temperature high-strain-rate superplastic medium manganese steel and preparation method thereof

A high strain rate, superplastic technology, applied in the field of high strength steel, can solve the problems of low forming speed and high forming temperature, achieve the effect of improving performance, realizing microstructure and inhibiting the growth of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

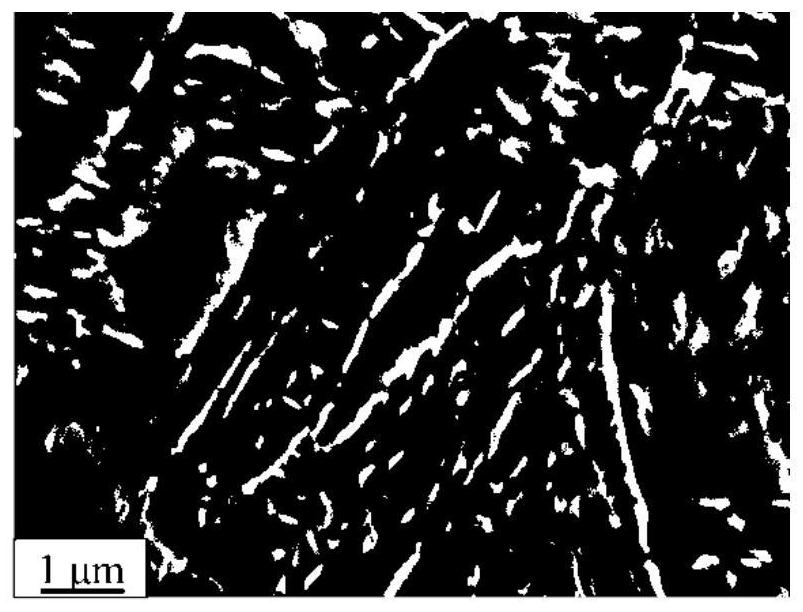

Embodiment 1

[0035] A low-temperature high-strain rate superplastic medium manganese steel, the chemical composition of which is calculated by mass percentage: C is 0.05wt%, Mn is 5.0wt%, Nb is 0.05wt%, V is 0.05wt%, and the balance is Fe and unavoidable impurities. The medium manganese steel has a duplex austenite and ferrite microstructure, the microstructure is uniform equiaxed austenite and ferrite grains, and the austenite and ferrite grains have the same size Below 0.3um.

[0036] The preparation method of above-mentioned medium manganese steel comprises the following steps:

[0037] Step 1, smelting: through vacuum smelting, the vacuum degree is about 80Pa, the raw materials are melted and micro-alloyed, and cast to obtain the required ingot;

[0038] Step 2, forging: heating the steel ingot to 1100°C, holding it for 3 hours, and forging it into a steel billet with a cross-sectional area of 100mm×40mm;

[0039] Step 3, low-temperature hot rolling: the steel billet is heated to ...

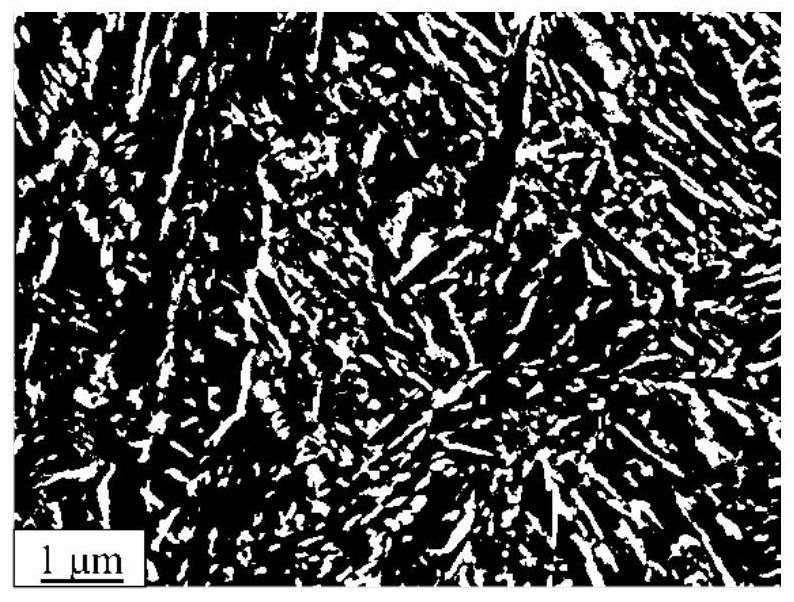

Embodiment 2

[0049] A low-temperature high-strain rate superplastic medium-manganese steel, the chemical composition of which is calculated by mass percentage: C is 0.15wt%, Mn is 8.0wt%, Al is 3.0wt%, Nb is 0.15wt%, V is 0.1wt% , the balance is Fe and unavoidable impurities. The medium manganese steel has a duplex austenite and ferrite microstructure, the microstructure is uniform equiaxed austenite and ferrite grains, and the austenite and ferrite grains have the same size Below 0.3um.

[0050] The preparation method of above-mentioned medium manganese steel comprises the following steps:

[0051] Step 1, smelting: through vacuum smelting, the vacuum degree is about 100Pa, the raw materials are melted and micro-alloyed, and cast to obtain the required ingot;

[0052] Step 2, forging: heating the steel ingot to 1200°C, holding it for 4 hours, and forging it into a steel billet with a cross-sectional area of 100mm×40mm;

[0053] Step 3, low-temperature hot rolling: the billet is heate...

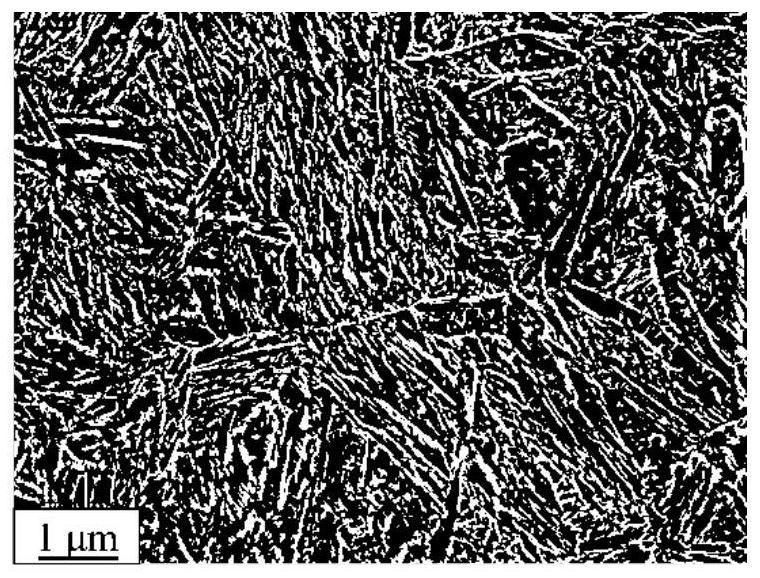

Embodiment 3

[0063] A low temperature high strain rate superplastic medium manganese steel, the chemical composition of which is calculated by mass percentage: C is 0.11wt%, Mn is 6.5wt%, Al is 1.4wt%, Nb is 0.05wt%, V is 0.08wt% , the balance is Fe and unavoidable impurities. The medium manganese steel has a duplex austenite and ferrite microstructure, the microstructure is uniform equiaxed austenite and ferrite grains, and the austenite and ferrite grains have the same size Below 0.3um.

[0064] The preparation method of above-mentioned medium manganese steel comprises the following steps:

[0065] Step 1, smelting: through vacuum smelting, the vacuum degree is about 100Pa, the raw materials are melted and micro-alloyed, and cast to obtain the required ingot;

[0066] Step 2, forging: heating the steel ingot to 1200°C, holding it for 3 hours, and forging it into a steel billet with a cross-sectional area of 100mm×40mm;

[0067] Step 3, low-temperature hot rolling: the steel billet i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com