Buoyancy box type flap valve and automatic opening and closing method thereof

A floating box and door panel technology, applied in marine engineering, construction, barrage/weir, etc., can solve the problem that the gate cannot be automatic, and achieve the effect of prolonging the service life, reducing noise and prolonging the overall service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

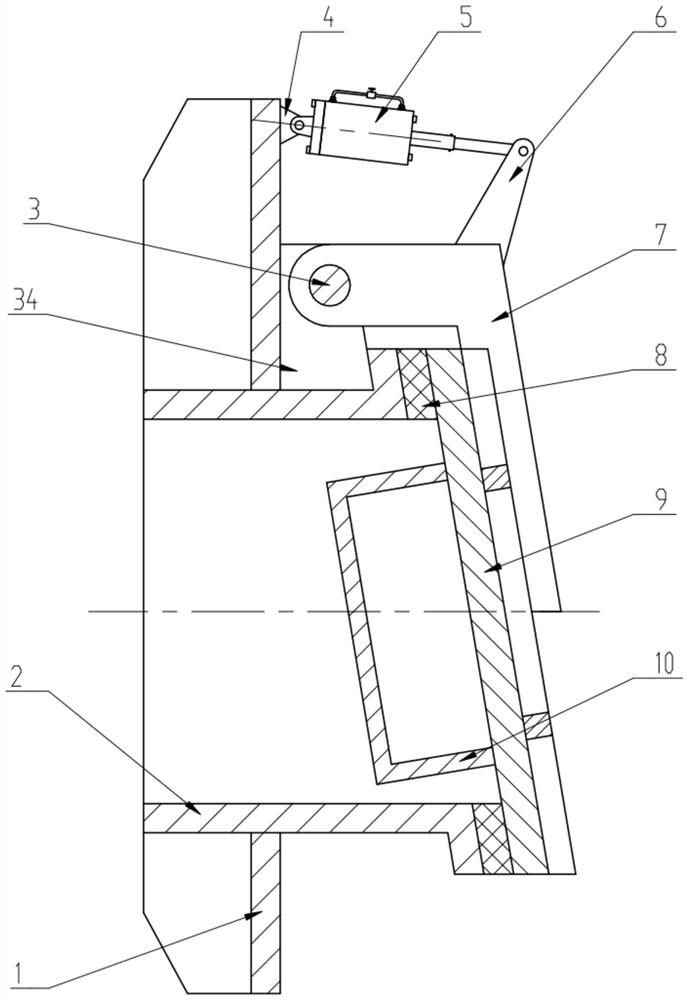

[0033] Such as figure 1 As shown, a buoyant box-type flap door and its self-opening and closing method include a vertical rectangular mounting plate 1, a cylindrical overflow pipe 2 that is fixed and fixed on the mounting plate 1 through a vertical Door panel 9 at outlet of flow tube 2. The door panel 9 and the flow pipe 2 are sealed and matched by the gasket 8 embedded in the right end surface of the flow pipe 2. The inside of the door panel 9 is welded with a closed circular box 10, and the outside of the door panel 9 is provided with 7 Glyph swing arm 7, the outer side of the door panel 9 is welded with reinforcing ribs, the lower end of the swing arm 7 is welded on the reinforcing ribs, and the left end of the swing arm 7 is hinged with the first lug 34 welded on the mounting plate 1, so The installation plate 1 is also provided with a slow closing device for slowly closing the door panel 9 , and the slow closing device is arranged above the overflow pipe 2 .

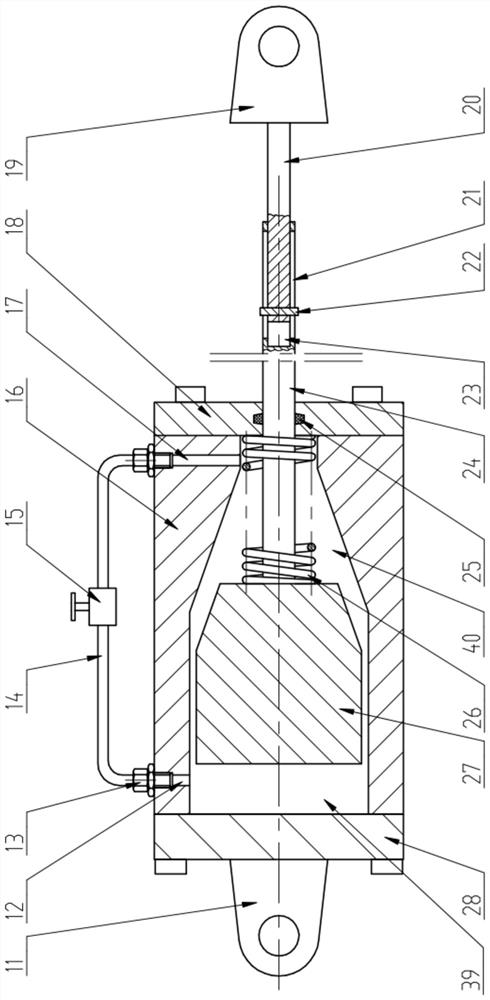

[0034] Su...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

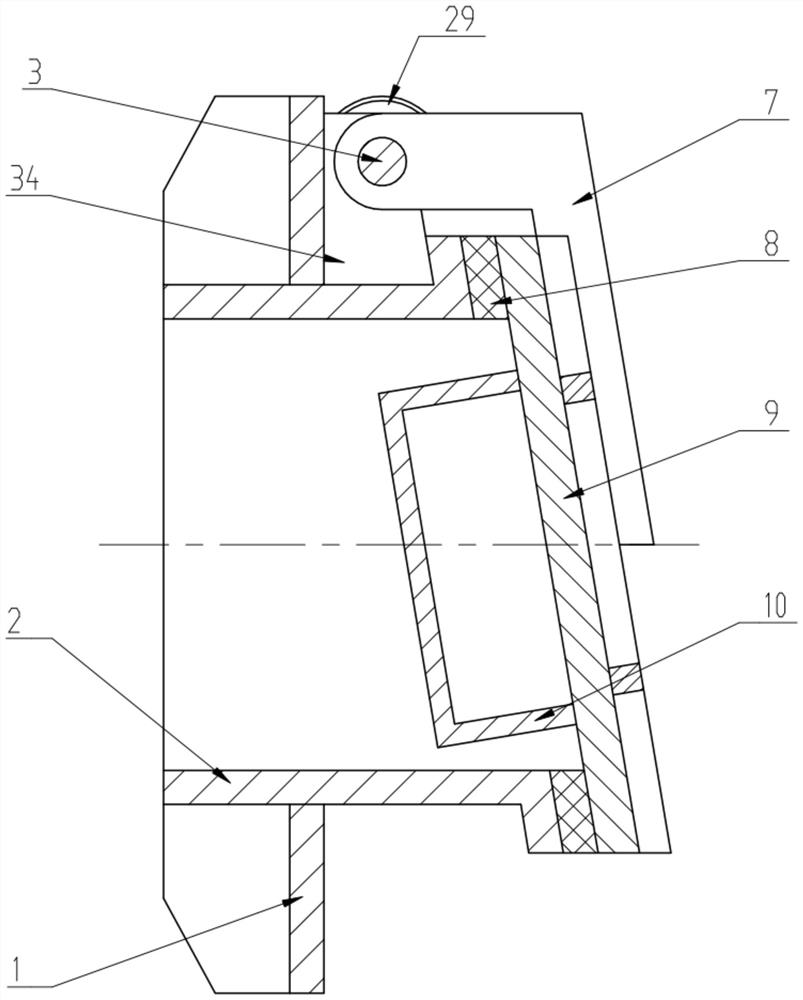

[0047] Such as image 3 The slow closing device shown is a disc damper 29 fixedly connected to the mounting plate 1, the shell of the disc damper 29 is fixedly connected to the mounting plate 1, and the upper left end of the swing arm 7 is fixedly provided with a hinge shaft 3. The hinge shaft 3 is rotatably connected to the first lug 34 .

[0048] Such as Figure 4 As shown, the hinge shaft 3 is provided with a disc-shaped first toothed plate 31, the first toothed plate 31 and the hinge shaft 3 are slidingly fitted, and the first toothed plate 31 and the hinge shaft 3 are connected by a sliding key . A disk-shaped second tooth plate 30 is provided on the right side of the first tooth plate 31 . The right side of the first tooth plate 31 has inclined first teeth 36 evenly distributed along the circumference, and the left side of the second tooth plate 30 has inclined second teeth 37 uniformly distributed ...

Embodiment 3

[0052] Such as Figure 5 Shown, the difference between this embodiment and embodiment 1 is:

[0053] The upper position of the door panel 9 is provided with a water injection screw plug 41 for injecting water into the box body 10 , and the lower position of the door panel 9 is provided with a water discharge screw plug 42 for releasing the water in the box body 10 .

[0054] Unscrew the water injection screw plug 41 to inject water into the casing 10, or unscrew the waterproof screw plug 42 to discharge the water in the casing 10, and adjust the water yield in the casing 10, thereby adjusting and increasing the downward force applied to the door panel 9, Thereby, the closing speed of the door panel 9 and the close force of the door panel 9 and the sealing gasket 8 are adjusted, so that the opening and closing of the door panel 9 can make the force adjustable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com