Offshore wind generating set cooling system adopting heat pipe for cooling

A technology for wind turbines and cooling systems, applied in wind turbine combinations, wind turbines, wind power generation, etc., can solve the problems of demagnetization of the permanent magnets of the wind turbines, reduction of the service life and generation time of the generator, and increase of the temperature of the engine room. Short lifespan, simple and compact cabin structure, and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

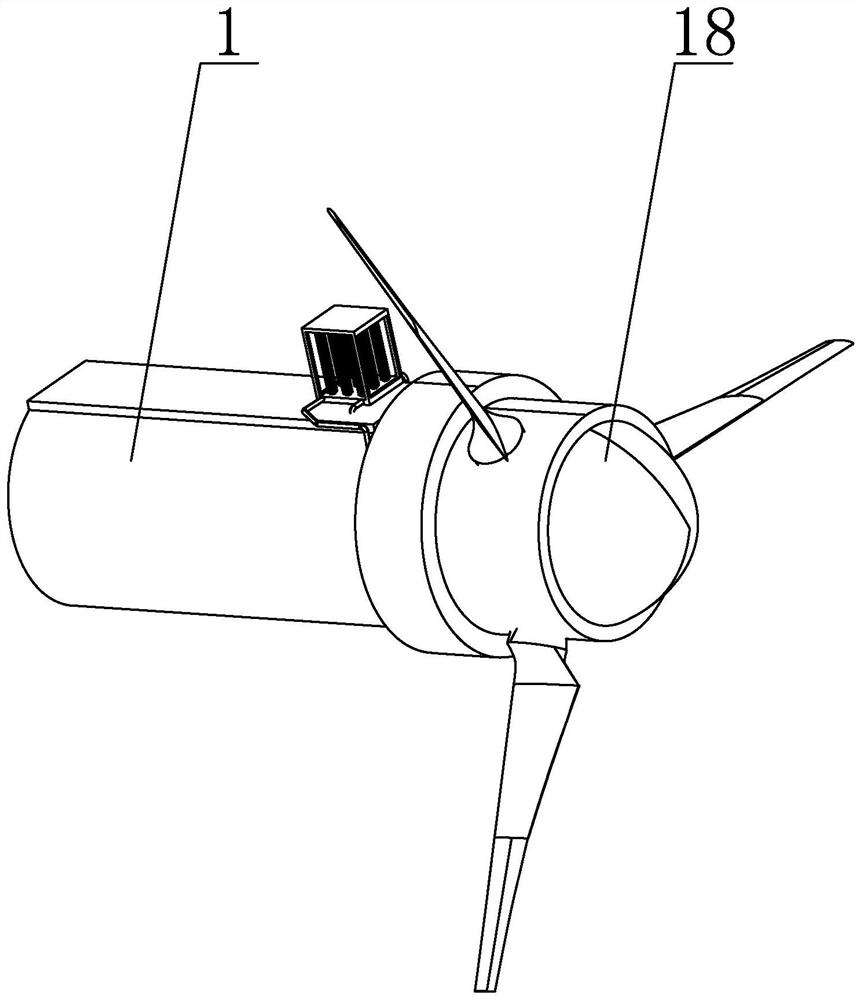

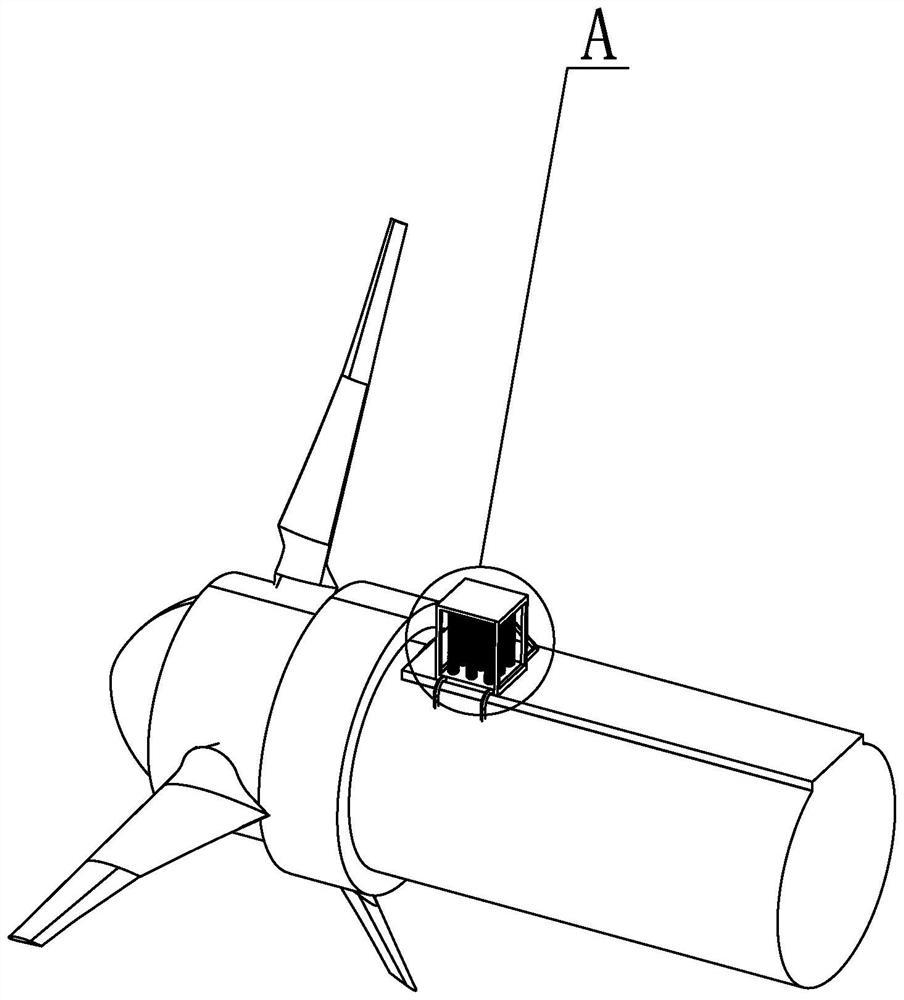

[0042] Specific implementation mode one: combine Figure 1 to Figure 8 This embodiment is described. In this embodiment, a cooling system for an offshore wind power generating set that adopts heat pipe cooling, the cooling system for an offshore wind generating set includes a generating set body, and the generating set body includes a cylindrical nacelle 1, a platform 2 and The direct-drive permanent magnet generator, the direct-drive permanent magnet generator includes the direct-drive permanent magnet generator stator 3, the cylinder cabin 1 is horizontally arranged, the platform 2 is horizontally arranged inside the cylinder cabin 1, and the platform 2 and The inner wall of the cylinder cabin 1 is fixedly connected, the direct-drive permanent magnet generator stator 3 is coaxially and fixedly installed on the front end of the cylinder cabin 1, and the stator 3 of the direct-drive permanent magnet generator is internally processed with a stator cooling circuit;

[0043] The ...

specific Embodiment approach 2

[0046] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the top end of the cylindrical nacelle 1 of this embodiment is provided with a nacelle boss along the length direction, and the heat pipe radiator 4 is fixedly installed on the upper end surface of the nacelle boss. In this way, in order to increase the internal space of the cylindrical nacelle 1 , the heat pipe radiator 4 is installed above the cylindrical nacelle 1 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

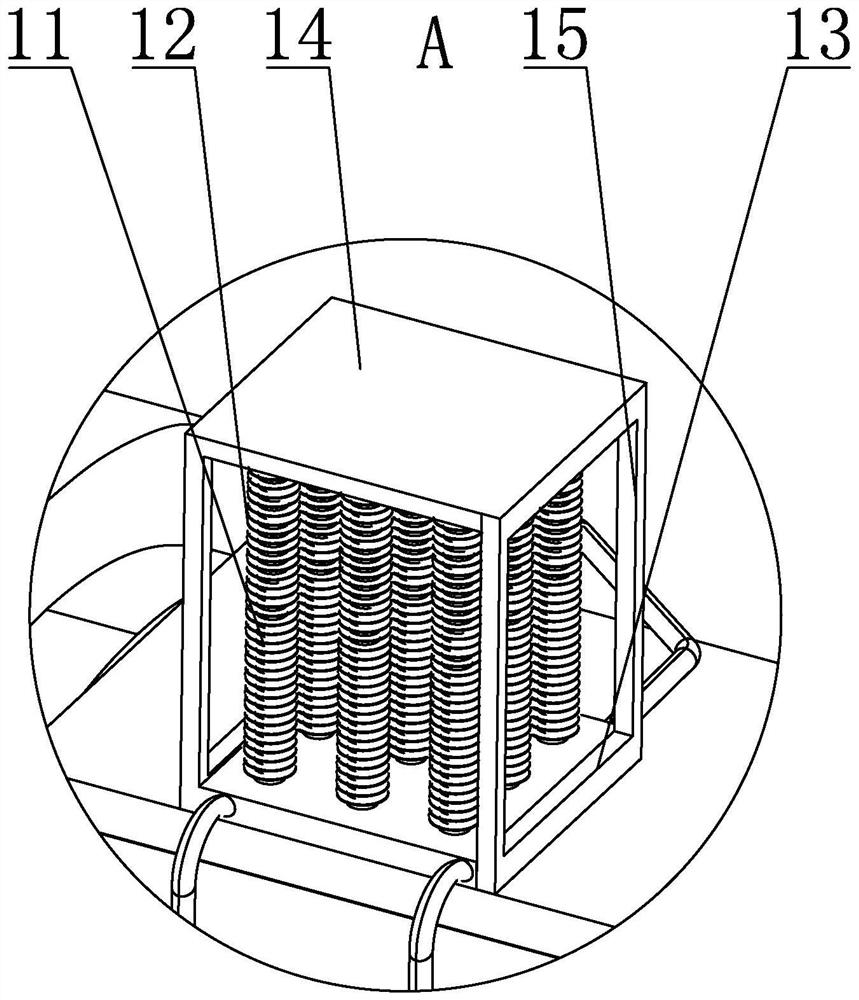

[0047] Specific implementation mode three: combination figure 2 and image 3 Describe this embodiment, the heat pipe radiator 4 of this embodiment includes a radiator body and a plurality of gravity heat pipes 11, a transition header is provided at the bottom of the radiator body, and a plurality of heat pipes connected to the transition header are processed on the upper end of the transition header. hole, a plurality of gravity heat pipes 11 are vertically arranged above the radiator body, and the gravity heat pipes 11 are condensing section, heat insulation section and evaporation section from top to bottom, and the evaporation section of gravity heat pipe 11 is inserted into the transition main pipe through the heat pipe assembly hole , the gravity heat pipe 11 is sealed and connected with the transition header. In this way, in order to make the heat dissipation efficiency of the external heat pipe radiator 4 not affected by seasons and weather, the gravity heat pipe 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com