Movable steam-injection boiler and moving method thereof

A steam injection boiler and mobile technology, applied in steam boilers, steam generation, earthwork drilling and production, etc., can solve the problems of large steam injection needs in heavy oil blocks, long steam injection time for single wells, and affecting oil production speed, etc., to achieve The effect of reducing the transportation size, occupying a small area, and increasing the output of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

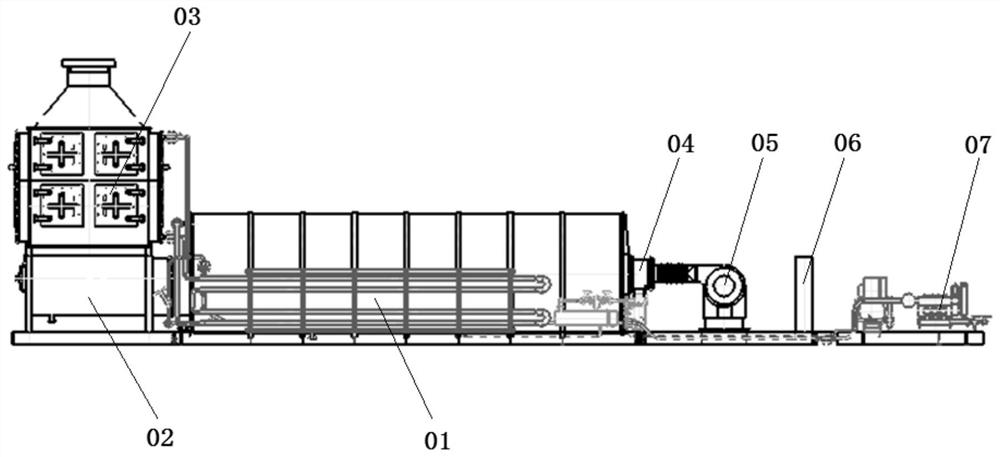

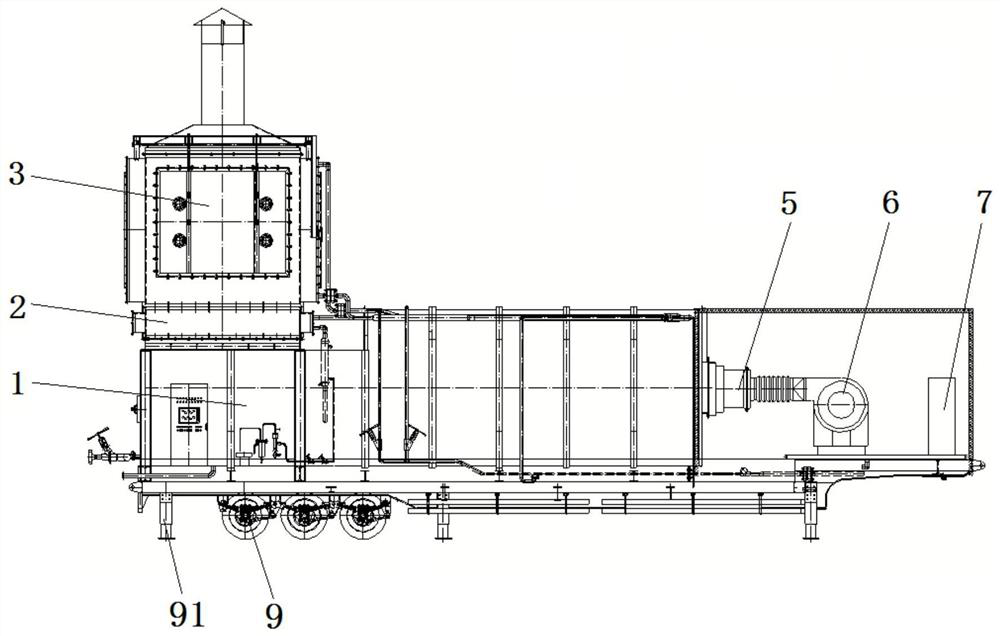

[0048] Such as Figure 3 to Figure 11As shown, this embodiment provides a mobile steam injection boiler, including a first module, a second module, a third module, a fourth module and a fifth module.

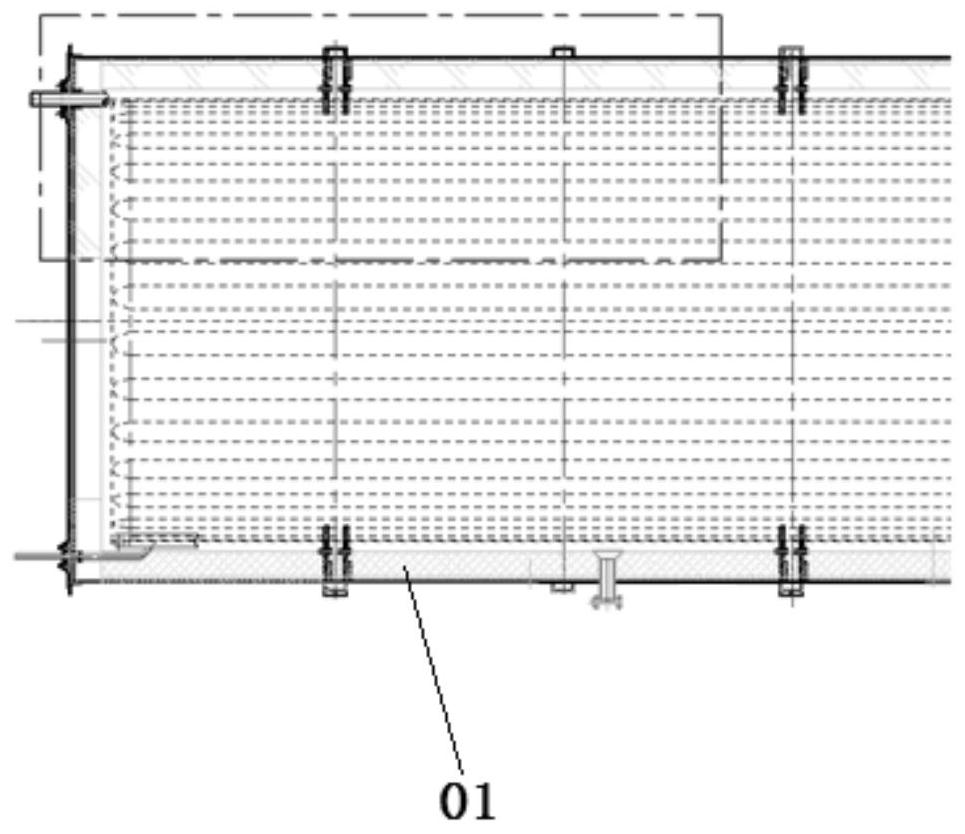

[0049] Among them, the first module includes boiler operation panel 7, burner 5, blower 6, radiation section 1 and water-water heat exchanger 4, the second module includes convection section 3, and the third module includes plunger pump 8 and air compressor , the fourth module includes the power distribution system, and the fifth module includes the venting equipment. The first module is installed on the first transport vehicle 9, the convection section 3 is installed above the tail of the radiation section 1, and the first module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com