Rotating disc type feed drying equipment

A kind of drying equipment, turntable technology, applied in the field of turntable feed drying equipment, can solve the problems of poor drying effect, low efficiency of drying means, feed agglomeration, etc., so as to improve drying effect and efficiency, improve Contact effect, effect of accelerating drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

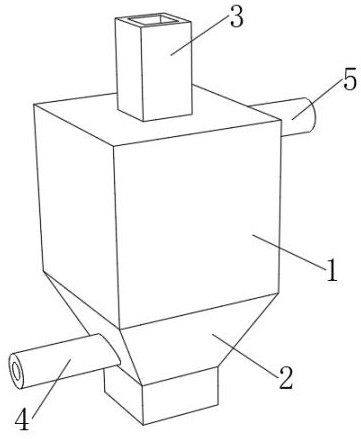

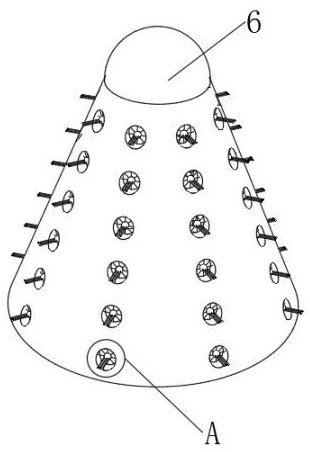

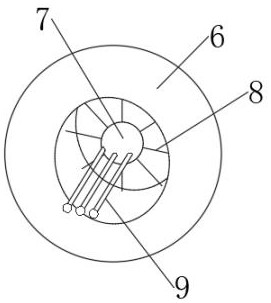

[0043] see Figure 1-4 , a turntable feed drying equipment, including a drying furnace 1, the upper and lower sides of the drying furnace 1 are respectively fixedly connected with a feed pipe 3 and a receiving hopper 2, the side ends of the receiving hopper 2 are equipped with an air inlet pipe 4, and the drying furnace 1 The side end is equipped with a suction pipe 5, and the inner side of the drying furnace 1 is provided with an outer casing 10, and a support column is fixedly connected between the outer casing 10 and the receiving hopper 2, and the upper end of the outer casing 10 is rotatably connected with a drying drum 6, and the drying drum A seal is embedded between the cylinder 6 and the outer disk 10, the inner end of the air inlet pipe 4 extends to the inner side of the receiving hopper 2 and is fixedly connected with the outer disk 10, the outer disk 10 is provided with an air inlet, and the air inlet pipe 4 passes through the air inlet The hole is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com