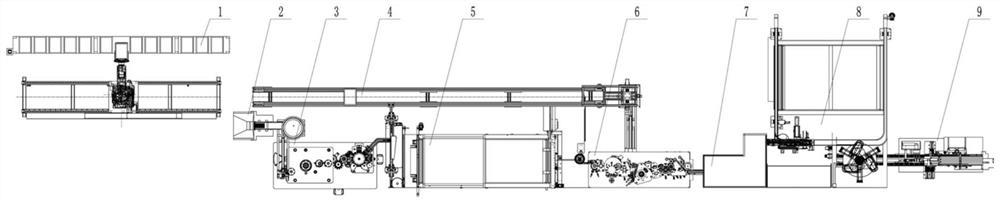

Automatic and continuous bullet assembling production line and assembling method

An assembly line and assembly device technology, which is applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve problems such as the inability to realize continuous assembly of bullets, achieve the effect of reducing labor demand and solving the effect of long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

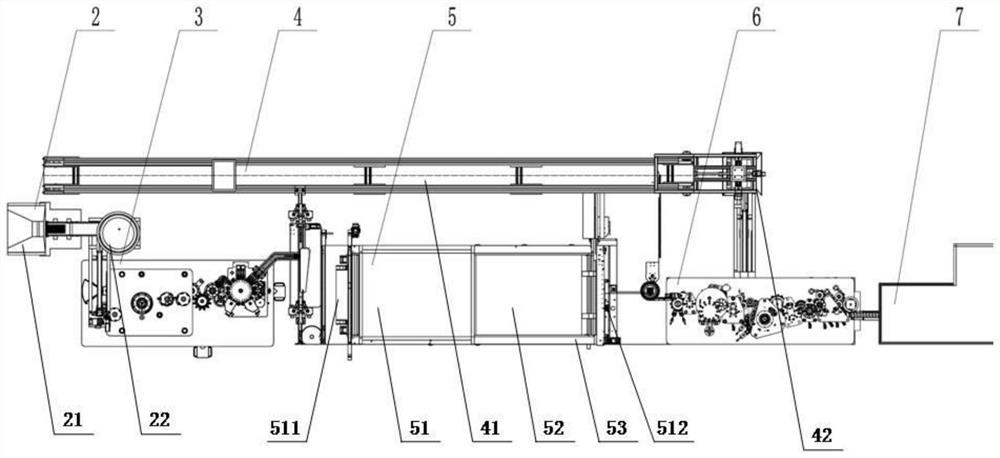

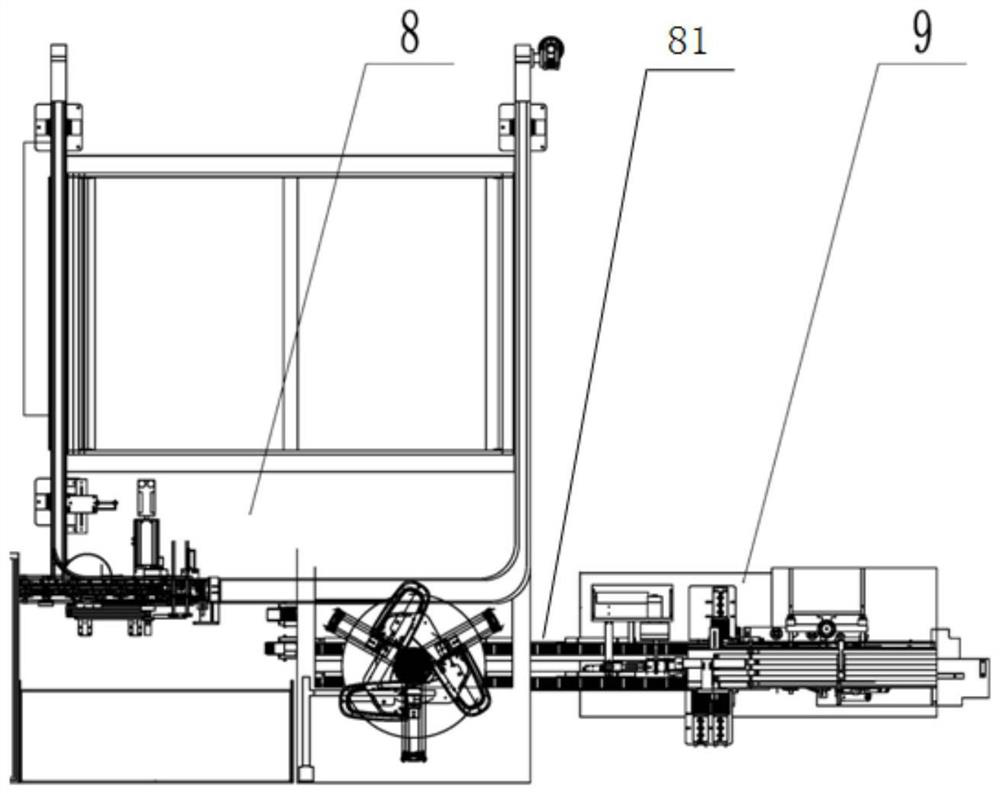

[0062] The existing bullet assembly and packaging technology is mainly based on single-process automation, and each process needs to be switched manually. The full-process automation and continuous assembly of bullets has not yet been realized, which makes the current bullet assembly efficiency low and the quality of bullets is low. Not high and the demand for assembly line staff is large. In view of this, this embodiment provides an automated and continuous bullet assembly production line, and reconstructs the bullet assembly generation mode. Because the existing bullet assembly process only realizes the assembly automation of a single process, that is, it is necessary to manually send the bullet parts into the shell assembly gluing device 3. After the assembly and gluing is completed, then manually send the bullet case and bullet into the full bullet assembly device 6 Synthesize the full bomb, and finally manually transfer the full bomb to the full bomb detection coating dev...

Embodiment 2

[0105] Corresponding to Embodiment 1, this embodiment provides a full-process automated and continuous bullet assembly method, including the following steps:

[0106] S1: Load the shells into the shell loading and sorting device, load the warheads into the warhead transmission and sorting device, and load the propellant into the full bomb assembly device;

[0107] S2: Start the CNC system, and drive each device on the production line to work through the drive module;

[0108] S3: Set the feeding and sorting rate of the shell case, the glue application rate of the shell case assembly and the drying time of the shell case through the shell case assembly control module, and set the bullet transmission and sorting rate through the bullet transmission sorting control module;

[0109] S4 uses the cartridge case loading and sorting device to take out a plurality of cartridge cases from the cartridge material temporary storage device, then sorts the taken out plurality of cartridge ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com