Heat energy storage test system and operation and control method thereof

A thermal energy storage and test system technology, applied in the direction of material thermal development, can solve the problems of manpower consumption, material and financial resources, poor flexibility, and high personnel costs, so as to reduce operation and maintenance costs, improve safety and accuracy, and improve human resources. effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

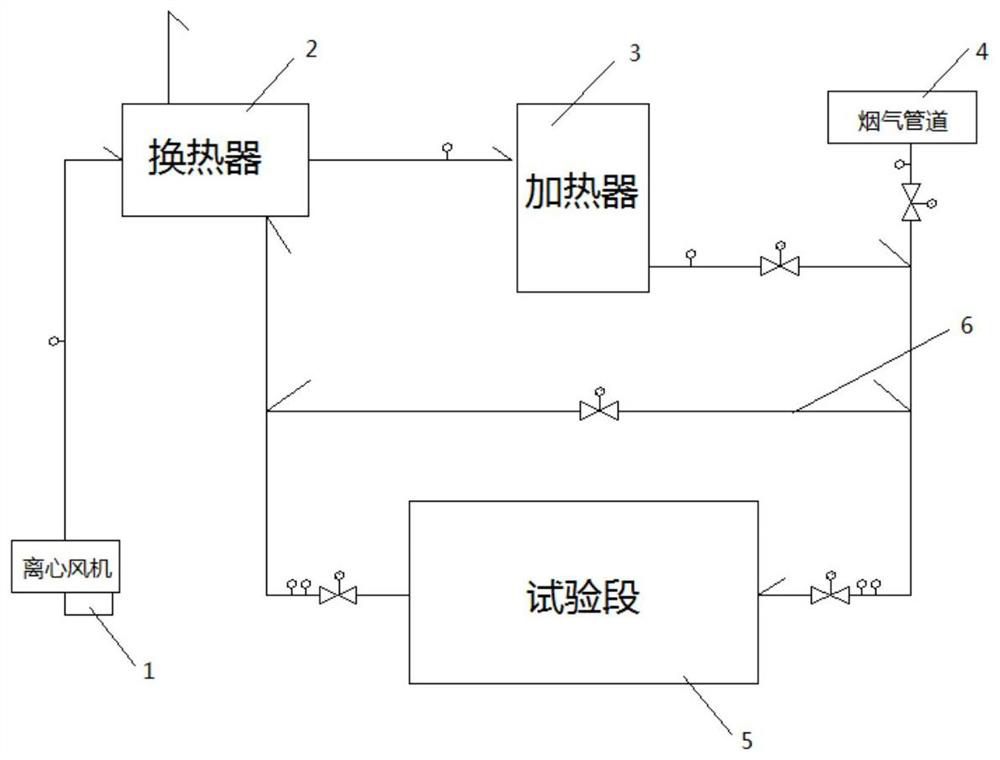

Method used

Image

Examples

Embodiment 1

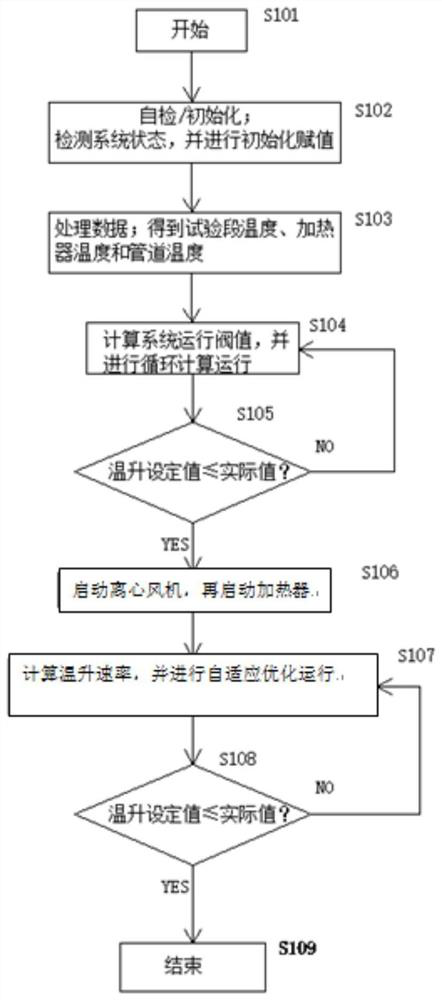

[0060] S101. Check the working status of each device, the working mode of the system and the initial logic of each switch are correct, and initialize and assign values to each status and each control parameter.

[0061] S102, assuming that the target temperature value of the test section 5 is TS S = 320°C;

[0062] S103. Collect the inlet temperature TS1 of the test section 5 = 100°C, the outlet temperature TS0 of the heater 3 = 125°C, and the temperature TS2 of each connecting pipe = 120°C;

[0063] S104, calculate the test start threshold T of the whole system 0 k, and perform cyclic calculation operation; T 0 k=TS1+H / 8=140°C, H is calibration time=320°C;

[0064] S105,T 0 k>TS0, execute S106;

[0065] S106, start the centrifugal fan 1, and then automatically start the heater 3; the start-up interval between the centrifugal fan 1 and the heater 3 can be 5s;

[0066] S107. Calculate the temperature rise rate ΔTem=5°C in the test section 5, then Q 风(i+1) =800;

[006...

Embodiment 2

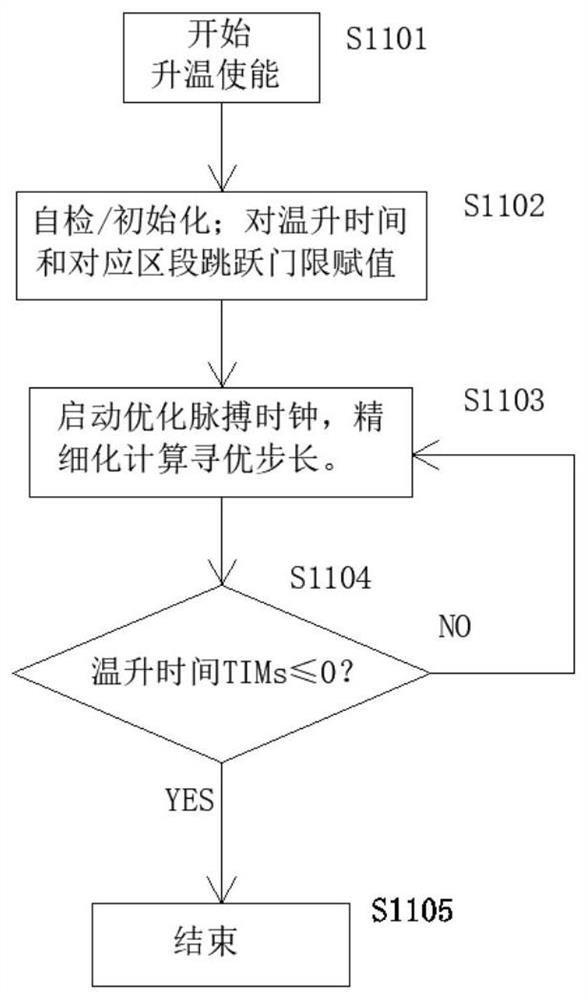

[0074] S1101, start, enable heating;

[0075] S1102. Set the temperature rise time of the test section 5 as section TIM 1 = 1h, TIM i =1h, the temperature rise section corresponding to each temperature rise time is TH 1 =130°C, TH i =135°C;

[0076] S1103. Start the self-learning optimization control pulse clock, and continuously calculate the dynamic temperature rise modulation step size ST according to the dynamic control refinement optimization self-applicable step size formula ki =0.08333°C / S, TIM i Enable ST ki action;

[0077] S1104. Continuously judge and update the control step size until the TIM of one test cycle ends and stops working.

[0078] The fourth technical solution provided by the present invention is a control method for refined cooling of the test section, based on a thermal energy storage test system, including the following:

[0079] S1201, start, enable cooling;

[0080] S1202, assuming that the cooling time of the test section 5 is respectivel...

Embodiment 3

[0084] S1201, start, enable cooling;

[0085] S1202, assuming that the cooling time of the test section 5 is respectively TIM 1 = 1h, TIM i =1h, the cooling section corresponding to each cooling time corresponds to TH 1 =135°C, TH i =130°C;

[0086] S1203, start the self-learning optimization control pulse clock, and continuously calculate the dynamic temperature modulation step size ST according to the dynamic control refinement optimization self-applicable step size formula k =-0.08333°C / S;

[0087] S1204 , continue to judge and update the control step size until the TIM of one test cycle ends and stops working.

[0088] The fifth technical solution provided by the present invention is an unattended automatic shift control method for the test section, based on a thermal energy storage test system, including the following:

[0089] S1301, start, enable the working system;

[0090] S1302, initialize the parameter setting, set the unattended running time TIM1 during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com